Video

Introduction

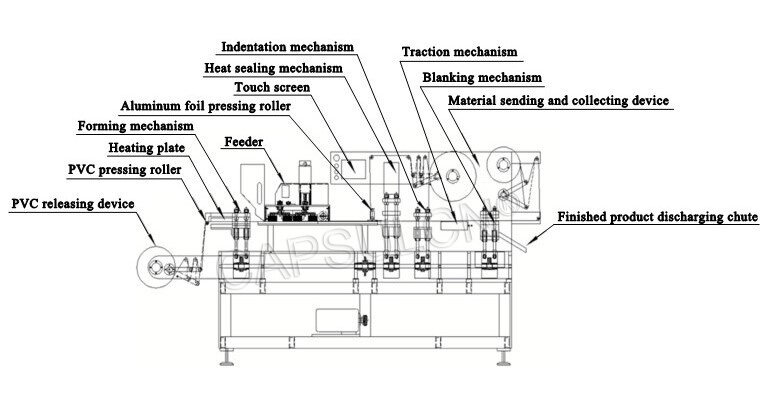

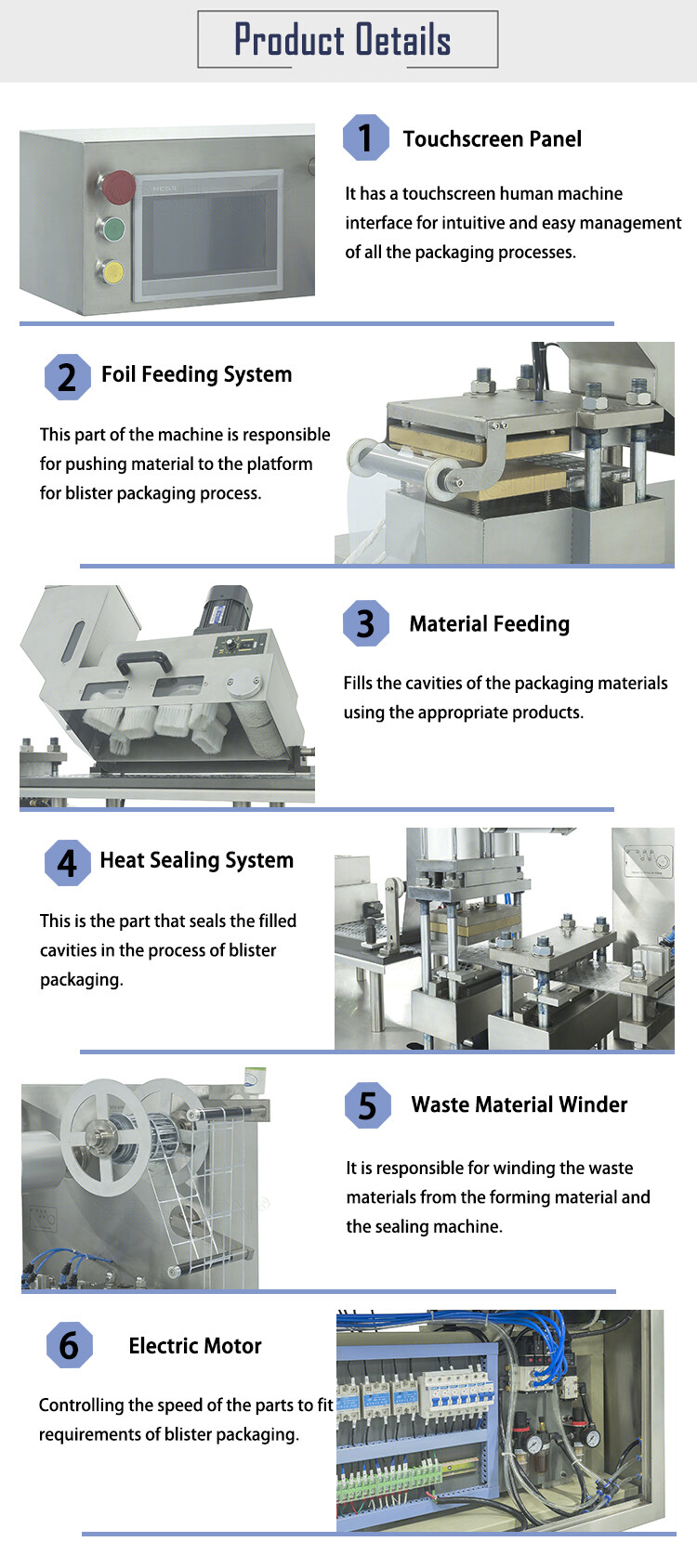

The product is specially designed for hospital dosage room, laboratory institute, health care product, middle-small pharmacy factory, and featured by compact machine body, easy operation, multi-function, stroke adjustable, long durability etc, it is suitable for the Alu-PVC package of medicine, food, electric parts etc. Aided forming Pre‐cutting Inspection and rejecting control systems. Print mark registration Automatic feeder

Features:

2. It utilizes frequency conversion stepless speed regulation, with blanking frequency 10~55 times/min.

3. It adopts the screw rod drive device. The packaging size of various sheets can be adjusted on the guide rail of the machine base at will.

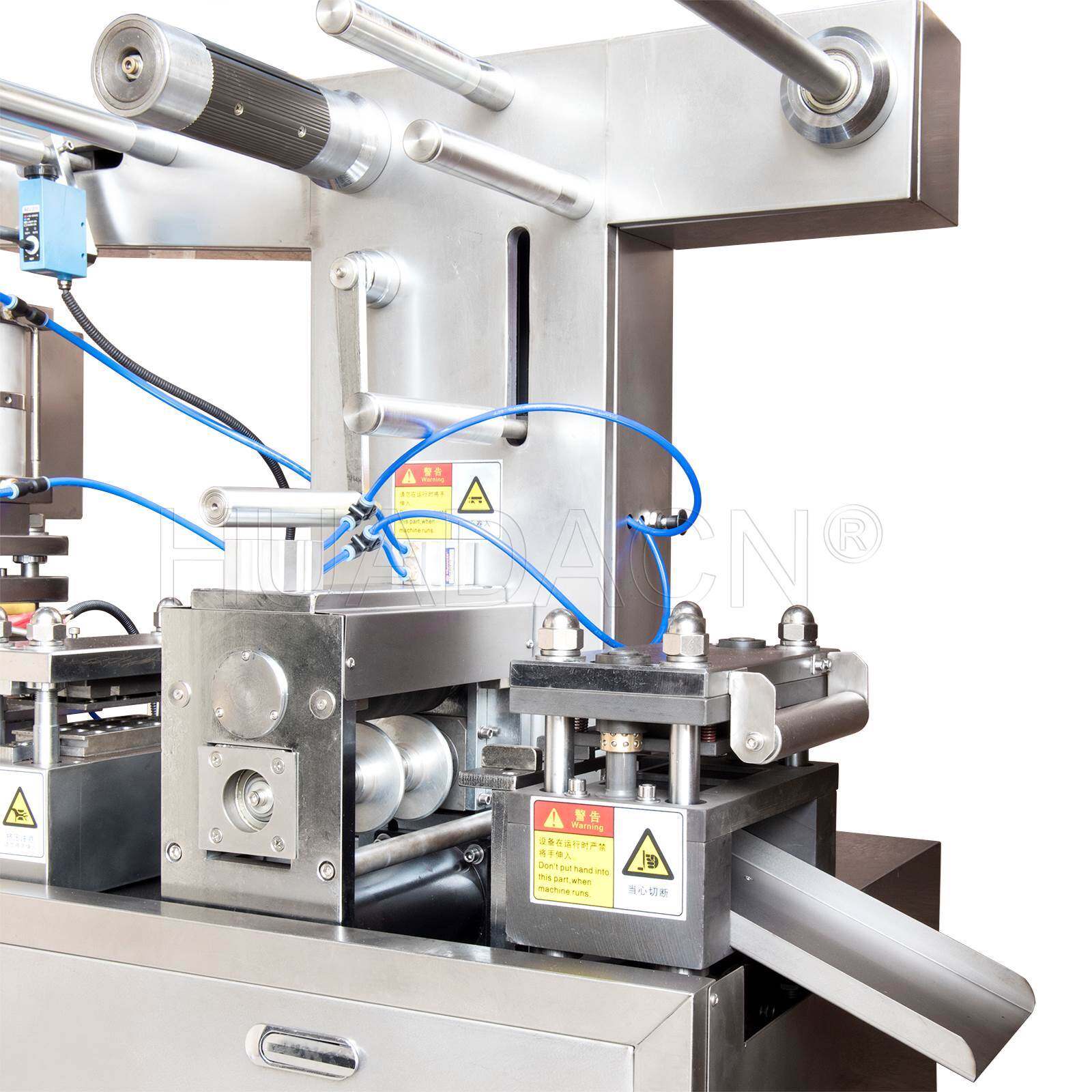

4. The pneumatic roller traction device is controlled by PLC, with simple structure and accurate operation. The traction stroke can be adjusted within the range of 10 to 500mm, which expands the application range of the machine.

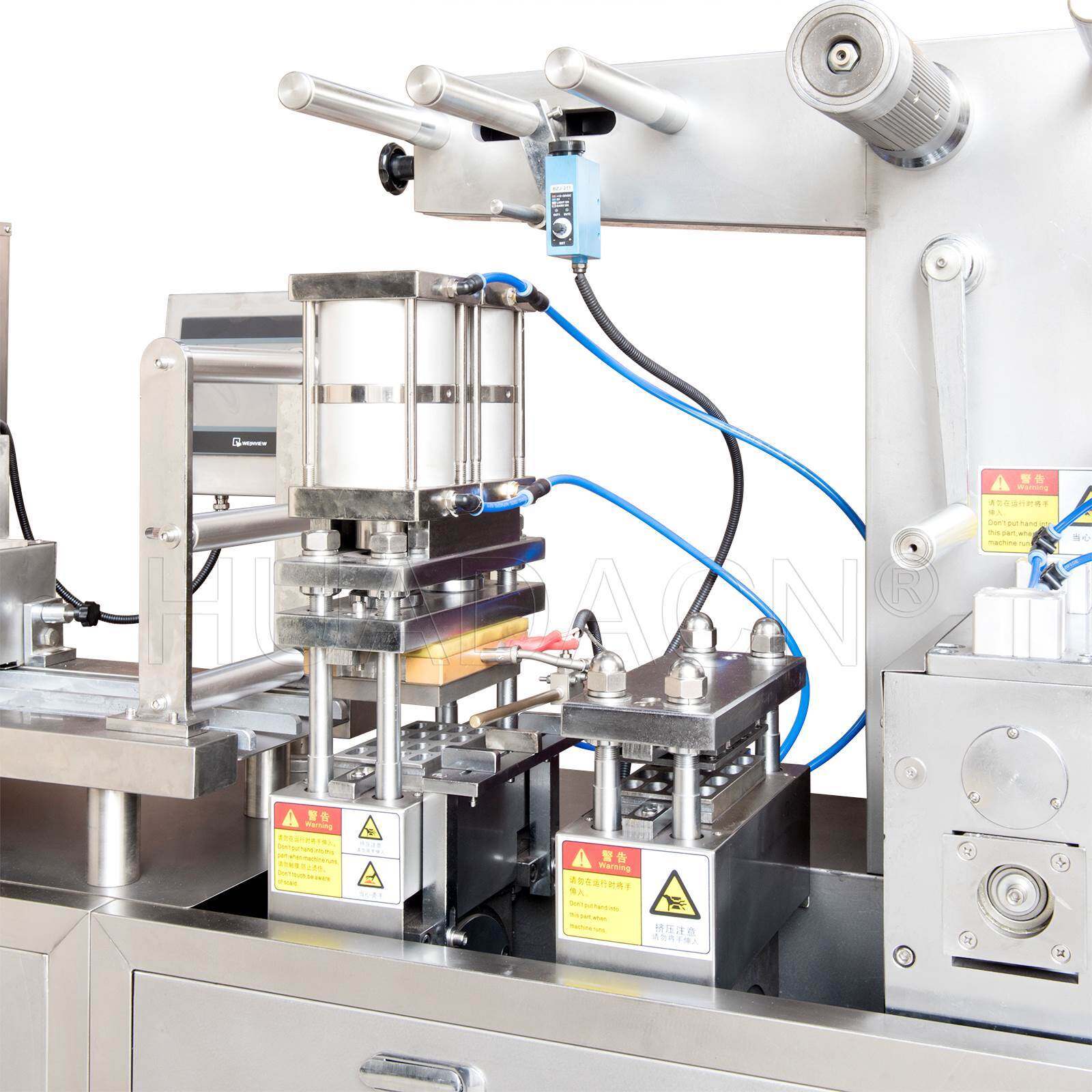

5. The molds for positive gas forming, heat sealing and indentation are fixed by pressing plate, with reliable positioning and convenient replacement.

6. If it is equipped with a universal feeder, the filling rate can reach over 99.5%. A dust suction interface can be installed to clean away dust caused in the process of feeding tablets.

7. The machine base and the machine body are separable. The whole machine is small in size and it has advantages of light weight, compact structure, simple operation, convenient transportation and maintenance.

Specifications

| Model | DPP-88 | DPP-140 | DPP-250 |

|---|---|---|---|

| Cutting frequency | 10-40 times/min | 10-50 times/min | 10-50 times/min |

| Capacity | 1980strip/h | 7200strip/h | 9600strip/h |

| Max shaping areas and depth | 130x90x16mm | 140x120x28mm | 270x150x28mm |

| Air pressure | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Power supply | 380V/220V 50Hz | 380V/220V 50Hz | 380V/220V 50Hz |

| Main motor power | 0.75kw | 1.1kw | 1.5kw |

| PVC hard pieces | 0.25-0.5*130mm | 0.15-0.5*140mm | 0.15-0.5*250mm |

| PTP aluminum foil | 0.02-0.035*130mm | 0.02-0.035*140mm | 0.02-0.035*250mm |

| Dialysis paper | 50-100g*130mm | 50-100g*140mm | 50-100g*250mm |

| Mould cooling | tap water or back water | tap water or back water | tap water or back water |

| Machine dimensions | 2070×650×1060 mm | 2050mm×526mm×1320mm | 3360X610X1670mm |

| Net weight | 560kg | 960Kg | 1500kg |

(Don't Worry! We have several Models. We can recommend you according to your requirement. Just Tell Us: Capacity, packing machine and Capsule Size.)

Remarks

- Best option for small batches, pharmaceutical R&D and pilot plants.

- It allows forming thermoplastic and cold forming materials (Alu-Alu).

- It stands out for its simple operation, high reliability and compact design. Its main structure is made of stainless steel.

- Automation by PLC and operation through touch screen control panel.

- It has pneumatic drives, which lend it high robustness and low maintenance.

- It is suggested for R&D departments, considering that its easy operation and maintenance makes it user-friendly to personnel that are not familiar with the use of blister machines.

review(s)

Strong durability

The mechanical durability is strong, and the products made are easy to use.

From: ruixue | Date: 3/2/2021 12:40 AM

Write your own review

Also Offers

Related products

Blister Packing Machine BM-Ⅳ

Blister Packing Machine DPP-140

Blister Packing Machine DPP-88

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche