Used in pesticides, veterinary drugs, food, chemical, biological, breeding industry, ceramics, refractory material, plastic, compound ferilizer, such as solid - solid (powder and powder) solid - plasma (i.e., powder and rubber slurry) mix,specifically adapted to viscous material mix.

Introduction

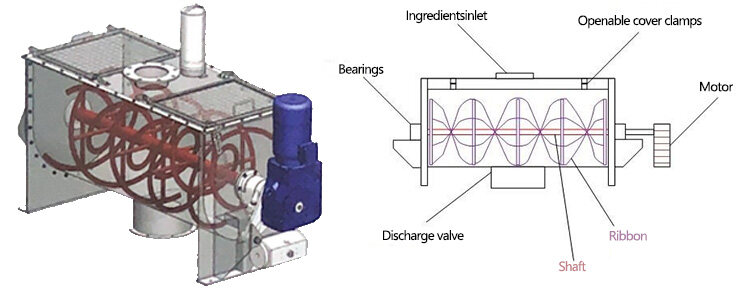

Ribbon Blenders consist of a U-shaped horizontal trough, transmission parts and ribbon agitating blades which usually have double or triple layers with outside screw gathering the material from sides to center and inside screw transmitting the material from center to sides to form convection mix and a specially fabricated ribbon agitator.

The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction. The ribbons rotate at approx. 300 fpm moves materials both radially and laterally to insure thorough blends in short cycle times.

Ribbon blenders are commonly used in nutraceutical, chemical, food and related industries. It is excellent for mixing both wet and dry products.

WLDH- Horizontal Spiral Ribbon Mixer Structure And Features :

Discharging mode:

Details Images

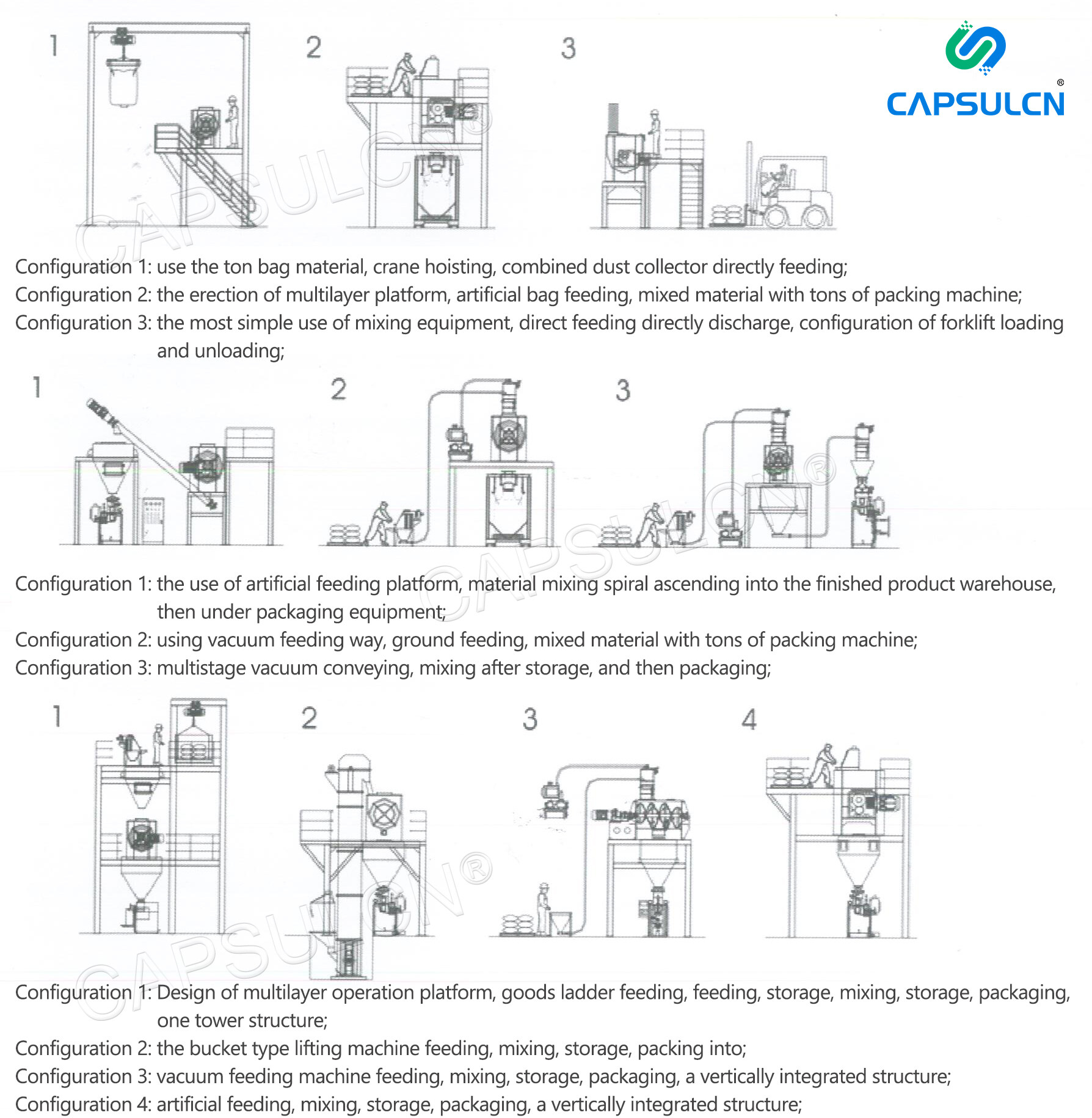

FIOW CHART :

Specifications

| Model | Total Volume(L) | Load Coefficient | Power(KW) | Dimensions(mm) | Weight (kg) |

|---|---|---|---|---|---|

| WLDH-100 | 100 | 0.4-0.8 | 3 | 1190x740x770 | 380 |

| WLDH-300 | 300 | 0.4-0.8 | 4 | 2320x730x1130 | 560 |

| WLDH-500 | 500 | 0.4-0.8 | 7.5 | 2800x920x1320 | 680 |

| WLDH-1000 | 1000 | 0.4-0.8 | 11 | 3180x1020x1550 | 1200 |

| WLDH-1500 | 1500 | 0.4-0.8 | 11 | 3310x1120x1640 | 1600 |

| WLDH-2000 | 2000 | 0.4-0.8 | 15 | 3750x1290x1820 | 2200 |

| WLDH-3000 | 3000 | 0.4-0.8 | 18.5 | 4220x1400x1990 | 3300 |

| WLDH-4000 | 4000 | 0.4-0.8 | 22 | 4220x1500x2100 | 3800 |

| WLDH-5000 | 5000 | 0.4-0.8 | 22 | 4420x1610x2260 | 4300 |

| WLDH-6000 | 6000 | 0.4-0.8 | 30 | 4700x2150x2470 | 5500 |

| WLDH-8000 | 8000 | 0.4-0.8 | 37 | 5520x2360x2720 | 6800 |

| WLDH-10000 | 10000 | 0.4-0.8 | 45 | 5720x2520x2740 | 7900 |

Remarks

- The machine is fully integrated and flexible.

- The stainless steel vessel is non- corrosive and allows dense liquids to turn freely and mix thoroughly without fading.

- Materials are poured manually.

- Operator- friendly.

review(s)

My brother

This machine is just like my brother and helped me make a lot of money

From: sevide | Date: 3/1/2021 1:20 AM

Write your own review

Also Offers

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche