All You Need To Know About Dosator Capsule Filling Machines

When it comes to capsule filling machines, you'll find they employ various dosing systems for a wide variety of applications, from commercial production to R&D laboratory use. The dosing systems are designed for different material fills to match the specific requirements of pharma products.

If you're going to fill solid dosage products, go for the auger fill method, mechanical vibration filling method, dosator method, and tamping pin/dosing disc method. The last two are currently the most popular filling systems used in the pharmaceutical industry.

As you can see, the working principle of automatic encapsulators are diverse. But in this article, I'd like to focus on the machine using the dosator system—Dosator Capsule Filling Machine. Let's read on to figure out what exactly the machine is and how it works.

What Is A Dosator Capsule Filling Machine?

Though many people don't know who invented the dosator capsule filling machine, it is likely that the concept originated in Italy. This machine has been available on the market for over half a century, and its work performance has greatly improved over time. Today, some machines can fill up to 250,000 capsules per hour.

These versatile machines are capable of filling powder, pellets, granules, and micro-tablets for large-scale production, lab use, and clinical trials. Also, it's worth mentioning that they can provide you with an accurate and reliable filling of dry powder inhalers (DPIs).

As its name implies, a dosator capsule filling machine distinguishes itself from its siblings by the core part—the dosator system. This system features several mechanisms—we'll get to them later—that are specifically designed to pick up accurate doses and fill them into the capsule bodies.

For further reading, check these two articles, and you will have a clear view of another type of capsule filler - the tamping pin capsule filling machine, and the difference between tamping pin and dosator capsule fillers.

Dosator Capsule Filling Principle

Let's now take a look at the working principle of the dosator-type machine.

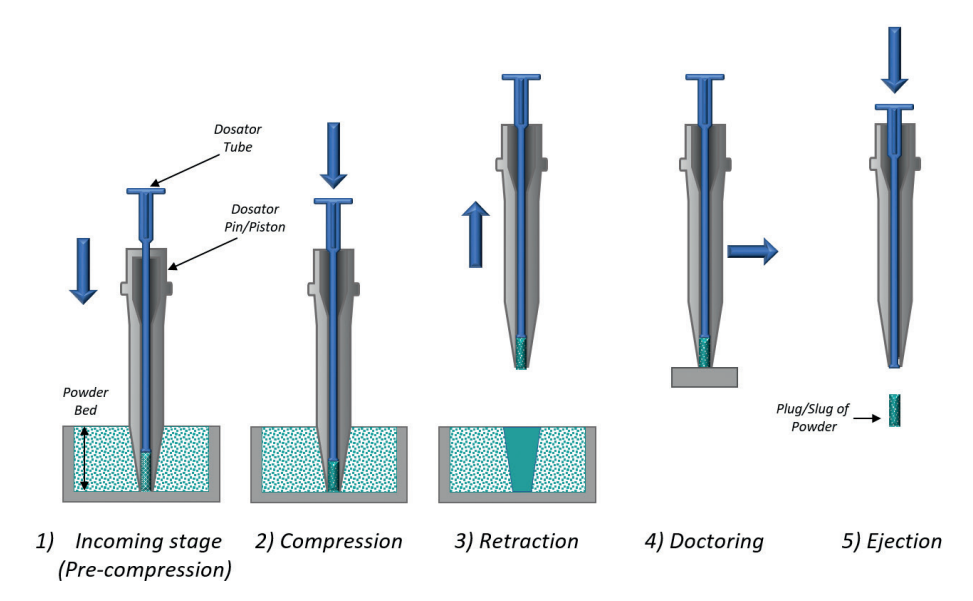

As mentioned previously, the dosator system plays a key role in the production process of this machine. It comprises the dosator tube and the dosator pin or piston to capture a dose. Here, let’s take the powder as the solid dosage form. The dosing operation is divided into five stages as follows:

1. The dosator descends into the rotating powder bed until its nozzle reaches the bottom of the vessel. This action enables the powder to flow into and to be held in the dosator cavity. In this stage, the powder inside the dosator is pre-compressed.

2. In stage 2, the dosator pin or piston moves down to compress the powder to form a plug. The compression should be sufficient to lock the powder within the dosator.

3. The dosator tube and piston are now retracted from the powder bed. The slug of powder is retained in the cavity.

4. Since the powder is cohesive, unwanted powders may adhere to the dosator nozzle. So, the doctoring stage is necessary.

5. The dosator aligns over the capsule body in the final stage. The piston descends to eject the powder plug. And then, the dosator moves back to the start position.

Apparently, the working principle of this system is fairly straightforward. If you've ever wondered how it works, I hope the description above will help.

So, what are the critical parts you need to know before running this machine?

The Most Important Parts of the Dosator Capsule Filling Machine

As with many automatic encapsulation machines, a dosator capsule filling machine is constructed with an array of mechanisms. Below, you'll find a slew of important parts that enable this machine to function efficiently.

Rotating Powder Bed

This open-top unit is designed for storing materials such as powder, granules, pellets, and micro-tablets. It works in a rotary motion with a defined height of fills.

Dosator System

The dosator comes in a cylindrical dosing tube with a pin or piston inside. As the critical part of the dosator capsule filling machine, this tool obtains doses at controlled weights from the powder bed and then transfers them to the capsule bodies.

Pneumatic System

The pneumatic system is commonly powered by compressed air to create linear or rotary motions of the machine. Driven by this system, the dosator pin or piston compresses the dose to form a plug and then locks it in the tube.

Vacuum System

Since most dosator capsule filling machines are fully automated, the vacuum system plays a big part in the production process. It allows for segment separation and tooling cleaning without manual intervention.

Lubrication System

The lubrication system is used to help the moving machine parts slide smoothly. To keep the machine running efficiently and reduce downtime, do not forget to equip your dosator capsule filling machine with an automatic lubrication system.

PLC Control System and HMI

The programmable logic controller (PLC) is in charge of all the machine operations by playing the role of a computer. Combining it with the human-machine interface (HMI) touch screen can greatly level up automation and efficiency.

Safety door

The safety door is one of the most important parts of the dosator capsule filling machine. Firstly, it protects operators from injuries during normal operations. Also, it ensures containment to some extent since the fills are exposed in the powder bed.

Read more: 10 critical capsule filling machine parts for high production

Why Dosator Capsule Filling Machine?

Having said all of the above, how can this machine benefit your business? Below are some of the biggest advantages of using the dosator capsule filling machine for your pharma manufacturing.

Filling Versatility

The dosator is not always designed for one single product. It's capable of filling hard capsules with a variety of solid dosage forms, including powder, pellets, granules, and micro-tablets. Recently, more dosators have been used to dose for DPIs. Further, this system can handle different capsule sizes as and when required.

Consistency & Precision

As a fully automatic capsule filler, the dosator can ensure, during the entire process, that each capsule carries the same dose based on the specific production requirements. Also, it can achieve precise filling of low-dose dry powder for inhalers at high speed.

Flexibility

The dosator features weight control, allowing for desired dosing volumes by adjustment of the plug length. So, it enables you to handle any dosage form in any fill volume based on your needs.

Integration

This automatic capsule filling machine can be integrated into a production line to boost production efficiency and save costs.

Scalability

Scalability is of great importance in pharma manufacturing. The dosator technology allows for the scalability of the filling process. If you want to take your company to the next level, this system can help scale up your manufacturing operations from the lab stage to high-performance production.

Conclusion

The information presented in this article will help you gather a better understanding of the dosator capsule filling machine. For people who plan to purchase an automatic capsule filler, the dosator is a solid choice to gain a higher ROI. At iPharMachine, we provide a selection of flexible encapsulation machines. Visit our website today to find the solutions you seek.

Leave your comment

Also Offers

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche