Introduction

This processing line is an advanced continuous equipment for producing candies of different sizes. It is an ideal equipment for producing high-quality products and saving manpower and space.

Syrup dissolving kettle——Gummy depositing machine——De-molding machine——Mould

1.Semi-automatic Tiltable Syrup Dissolving Kettle

This is using for cooking the syrup.

| Model | CndCN-Pot S100L |

| Temperature | 0-145℃ |

| Capacity | 100L |

| Power | 13kw |

| Size(mm) | 1300*800*1250 |

| Weight | 200 kg |

| Reduction ratio | 1:60 |

| Temperature control table | Omron |

| Motor | Siemens |

| Heating style | Electic |

2.Semi-automatic Pedaled Gummy Depositing Machine

This is a semi-automatic candy depositing machine that can deposit various shapes of candies. Put the mold under the depositing hopper by hand, then deposit it, and take out the mold after depositing.

| Model | CndCN-Mol S20 |

| Power | 4 kw |

| Size(mm) | 800*800*1700 |

| Weight | 200 kg |

| One-time depositing | 20 pcs (candy quantity can be customized) |

| Depositing Speed | 10-30n/min |

| Material | SUS 304 |

| Capacity | 30L |

| Production Capacity | 30 - 50 kg / h |

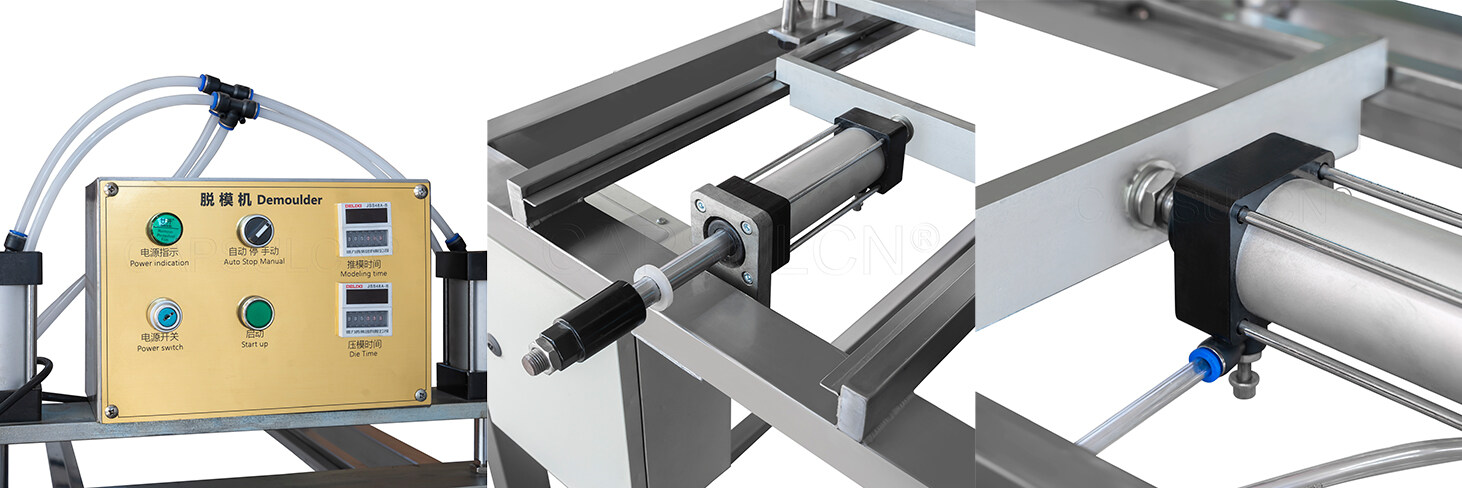

3.Semi-automatic Candy/Gummy Demolder

This is an optional device to improve production efficiency.The device is suitable for semi-automatic production line.

| Model | CndCN-Dem S |

| Size(mm) | 420*220*500 |

| Weight | 15 kg |

| Material | aluminum alloy |

| Production Capacity | 30 - 50 kg / h |

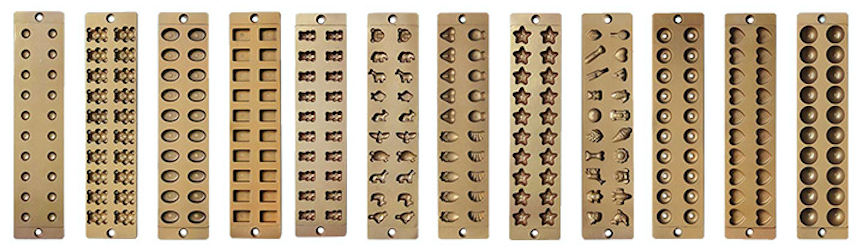

Mould (shape can be customized)

Main Application

Candy shape can be customized.

Write your own review

Also Offers

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche