New Arrival

Big Promotions

Recommend

About iPharMachine™

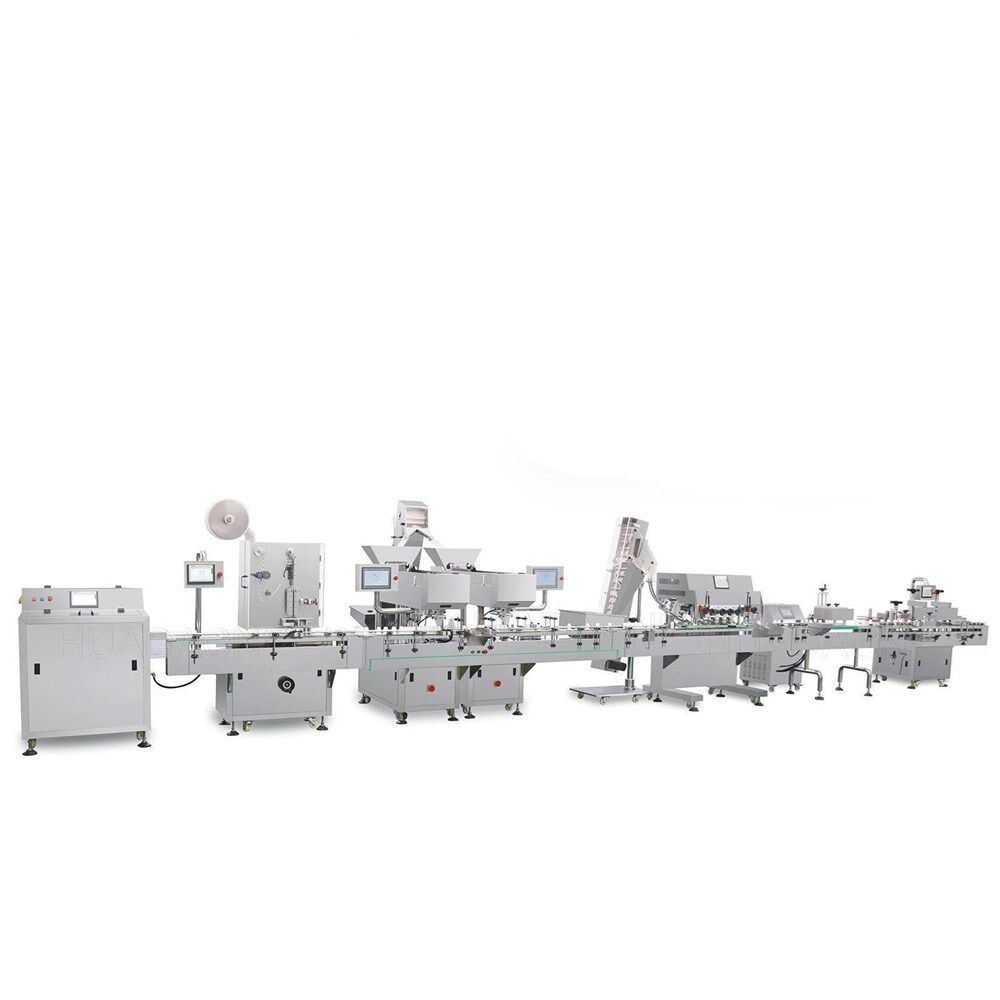

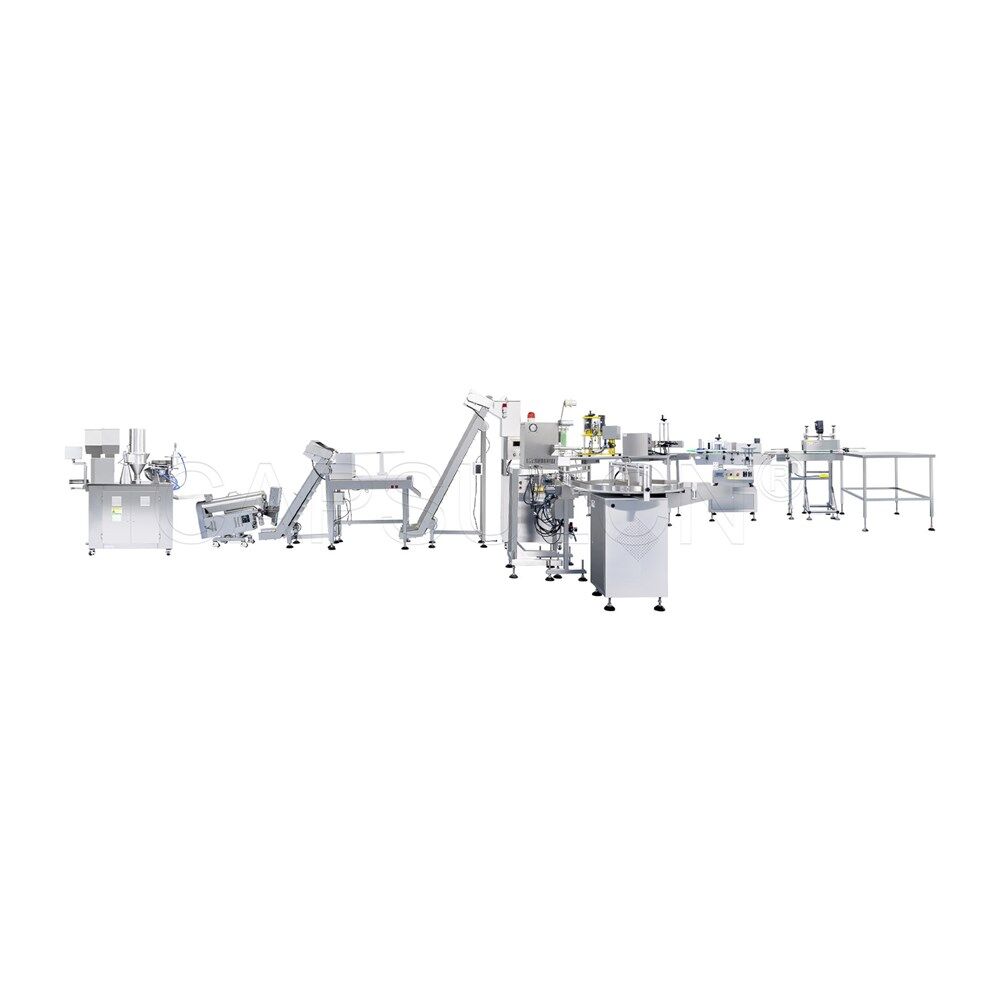

Capsule Production Equipment mainly consists of capsule filling machine and capsule polishing machine, using empty capsule and powder to produce finished capsule. The machine can process most capsules including softgel, gelatin capsule, vegetarian capsule.

If you are looking for machinery that can skyrocket your pharmaceutical productivity, feel free to check out our large-scale pharmaceutical equipment.

Featured products

Bestsellers

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche

News

iPharmachine at Vitafoods Asia 2023 in Thailand

Thursday, September 21, 2023

Professional Pharmaceutical Packaging Solution in Vitafoods Asia 2023! Wait you at Queen Sirikit National Convention Center. Contact us Now!

Join Us at CPHI South East Asia 2023

Monday, July 10, 2023

CapsulCN will participate in CPHI South East Asia 2023. We will be at booth #D06 to serve any visitors interested in our pharmaceutical equipment solutions.

CapsulCN sent its elite-level sales and tech pros to the U.S. for field service

Wednesday, October 19, 2022

On October 8, 2022, a team of CapsulCN’s sales and technicians headed to the U.S.

Resource

What is a Labeling Machine: An Ultimate Guide

Do you want to know what a labeling machine is and why it is important for your project? Check out this post and get to learn everything about labeler machine!

Thursday, March 21, 2024

Top 10 Cartoning Machine Manufacturers in the World 2024

Looking to take your packaging business to the next level in 2024? Here’s a list of the top 10 global cartoning machine manufacturers worth working with.

Thursday, March 21, 2024

Advantages of Carton Packaging You Didn’t Know

Are you considering purchasing a carton packaging machine? Read this article now! Find out what advantages carton packaging has over other packaging methods.

Friday, March 15, 2024

Top 9 Cartoning Machine Parts You Didn't Know Before

Are you curious about the important parts of a carton sealing machine? Check out this blog! It covers everything you need to know about cartoning machine parts.

Thursday, March 14, 2024

Exploring the Cartoning Machine Working Principle

Looking to get the most out of your cartoner? Understanding the cartoner principle is crucial. This post will discover the inner workings of the machine.

Thursday, March 7, 2024

All You Need to Know about Cartoning Machines

Cartoning machines are the most common packaging equipment. What is a cartoner? How does it work? Why use it? Read our post to get all the answers you need.

Thursday, March 7, 2024