Also bought

Introduction

This machine is used mainly in such trades as pharmacy, chemical industry, food, pottery and plastics extensively, making moist powder material particle. Make cylinder swing reciprocatly, extruding material from screen mesh for granulation. It also can be used for crushing the agglomerate materials into small granules directly.

It is very suitable for materials of high viscosity.

It has the characteristics of simple and reasonable structure, advanced granulating method and energy saving. Due to its effect of even granules, little powder content, long service life and compliance with the GMP standard, the machine is suitable for manufacturing granules of various specifications in pharmaceutical, chemical, food and other industries.

Structure

Machine body

The machine body is an independent cuboid, which is composed of bearing support, speed reduction gearbox and machine base. It can be placed in the room directly without installation.

Granule manufacturing device

The rotary roller is just below the hopper, and there are bearing supports at the front and rear. It is driven by the rack to rotate clockwise and then anticlockwise at regular intervals. The front bearing seat on the end face is movable. Simply by unscrewing three screws on the seat, the front bearing seat and the rotary roller can be pulled out in turn.

Clamping tubes of screen mesh

They are made of stainless-steel tubes and installed on both sides of the rotary roller. There is a long groove in the middle. The two ends of the screen mesh are embedded in the groove. Rotate the handle to wrap the screen mesh on the outer circle of the rotary roller. The ratchet is used to support the hand wheel. The tightness can be adjusted.

Reduction gearbox

It utilizes worm drive. Machine oil can be stored in the box to ensure the good lubrication and no noise of gear rod, gear and worm gear.

Machine base and motor

The motor mounting plate is hinged with the machine base, and its other end is hinged with the adjusting nut.

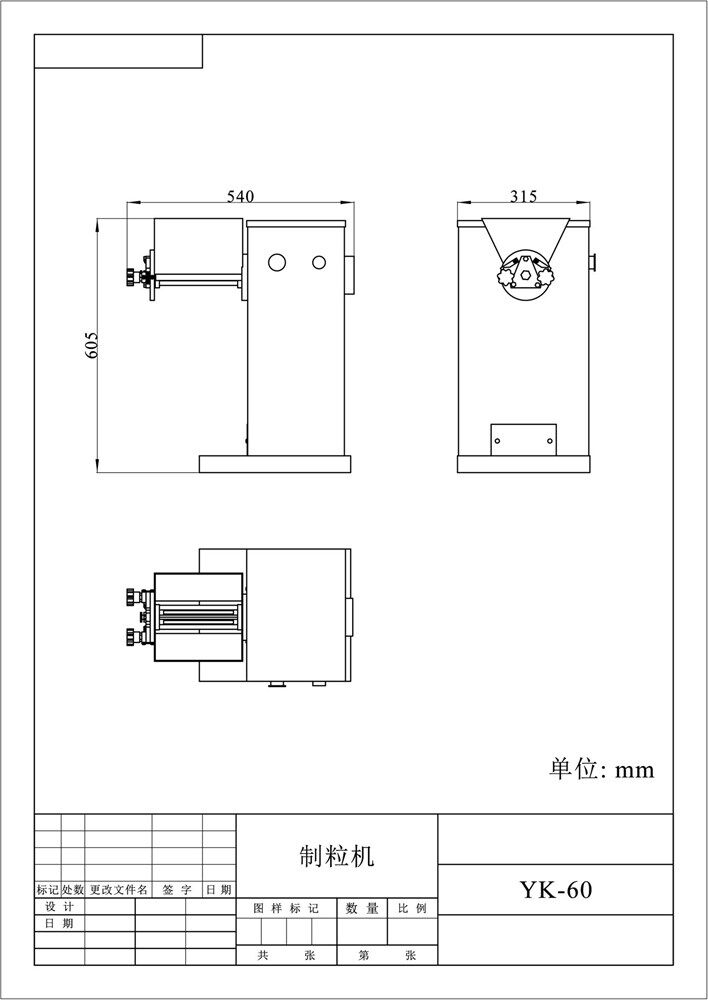

Specifications

| Model | CYK60 | CYK90 | CYK160 |

|---|---|---|---|

| Production capacity |

Dry materials: 30 kg/h; Wet materials (12mesh): 20kg/h |

Dry materials: 100kg/h; Wet materials (12mesh): 30kg/h |

Dry materials: 700 kg/h; Wet materials (12mesh): 300kg/h |

| Diameter of roller (mm) | 60 | 90 | 160 |

| Effective length of roller (mm) | 184 | 270 | 360 |

| Roller speed (r/min) | 46 | 46 | 46 |

| Hopper inlet (L*W) (mm) | 210*210 | 300*270 | 410*380 |

| Power(kw) | 0.55(220V) | 1.1(220V) | 5.5(380V) |

| Machine weight | 70 kg | 150 kg | 260 kg |

| Overall dimension (L*W*H) (mm) | 330*550*570 mm | 750*460*840mm | 970*750*1240 mm |

Remarks

- It is not suitable for solid, fluid medium, paste or pulverizing.

- The mesh number of meshed sieve should be prepared by users themselves according to the size of granule.

review(s)

Like

I like this machine very well. Give me some time to see if it is durable.

From: Jack | Date: 3/1/2021 1:52 AM

Write your own review

Also Offers

Related products

Vibrating Granulator CYK Series

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche