Also bought

Introduction

This machine is a kind of special equipment for pharmacy. It is driven by variable speed control, polish and clean powder on pills or tablets to get smooth products and meet hygeian standard of pharma industry. It is suitable for various kinds of pills and tablets.

The performance of the whole machine is good. The machine is made of stainless steel, and the mesh cartridge and the brush are connected by compression fitting, easy to assemble and disassemble, and can be cleaned thoroughly. Also, the motor speed is controlled by the inverter and can withstand large starting torque, which makes the machine run smoothly and reliably. In addition, equipped with flexible rollers, it is convenient for the machine to move. Hence, the machine is easy to operate, reliable, high in production efficiency and the polishing cleanliness.

Remarks

- This machine includes pedestal, machine frame, canister, brush and electrical system. Adopts special DC motor, import polishing brush and spiral feeding in-and-out accessory. This machine is light weight, novelty structure, good appearance, simple operation and high efficiency.

- Before electrifying, turn around the main shaft manually to ensure the shaft is under good condition.

- Before polishing different kinds of capsules, please clean the brush, net, and hopper completely.

- Clean the filter bag of the dust-collector.

Specifications

| Model | YPJ-III |

|---|---|

| Capsule Model No. | 00# 0# 1# 2# 3# 4# |

| Output Capacity | 10000 pcs/min |

| Power Supply | 220V 50Hz/110V 60Hz |

| Power | 0.18kw |

| Dimension | 1025*550*900 (mm) |

| Weight | 40kg |

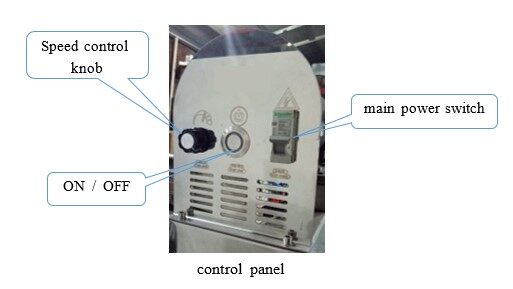

Main structure

review(s)

Best

The pills and capsules are cleaned up very clean and can meet hygienic standards

From: Isabella | Date: 3/1/2021 3:32 AM

Write your own review

Also Offers

Related products

Blister Packing Machine BM-Ⅳ

Automatic Capsule Filler & Encapsulation Machine NJP-1200C

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche