Video

Introduction

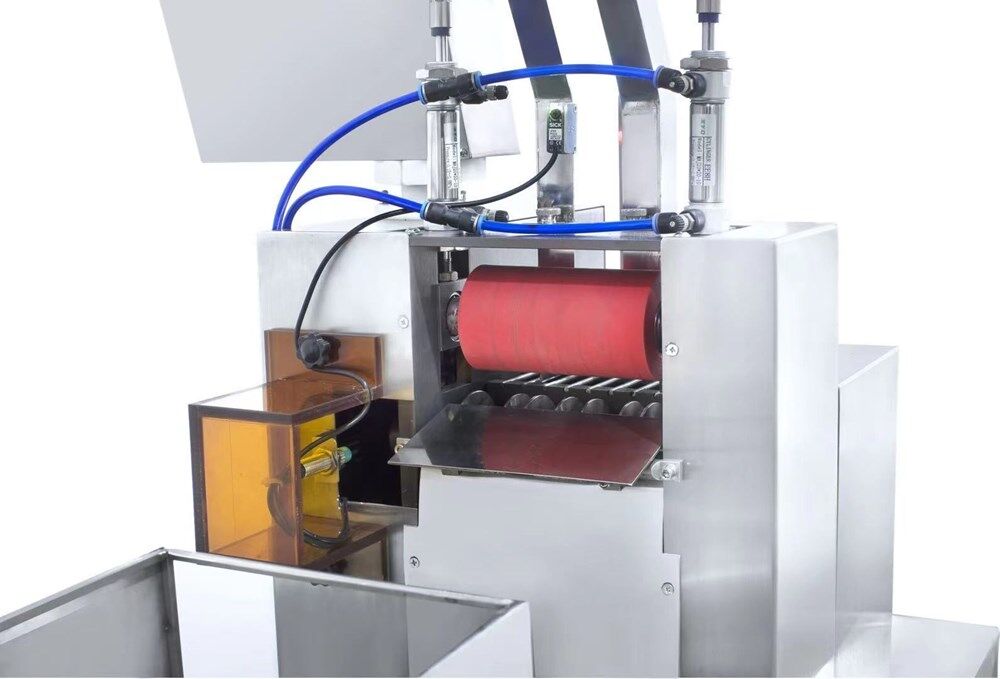

PY-120B Intelligent Blister Peeling-off Machine is an efficient equipment for recycling capsules or tablets in blisters to be checked. The equipment can be applied in pharmaceutical companies’ preparation workshop to separate various specifications of capsules and tablets from aluminum-plastic, aluminum-plastic-aluminum, and aluminum-aluminum blister sheets.

PY-120B is an automatic high-speed blister peeling-off machine which can recycle the capsules or tablets in the defective aluminum-plastic blister sheets. It can separate all the capsules or tablets from the defective blister sheets. With the help of the guide plate and tablet blocking rubber plate, the capsules or tablets and the blister sheets can be collected separately.

Specifications

| Model | PY-120B |

|---|---|

| Production capacity | 90~120 sheets/min |

| Specification | 45mm * 145mm (Adjustable stroke) |

| Control panel | Touch screen PLC |

| Power supply | 220V/50Hz |

| Compressed air | 0.4 MPa |

| Working noise (average) | 50 dB |

| Motor power | 160W |

| Machine size | 470*1400*770 (mm) |

| Machine weight | 70 kg |

| Stainless steel frame (306/316L optional) | √ |

| Material level sensor detection | √ |

| Capsule/Tablet counting, total output counting | √ |

| Aluminum foil rejection function | √ |

| Faulty capsule elimination function | √ |

| Capsule/Tablet collecting container | √ |

| Waste blister collecting container | √ |

Remarks

- It is intelligently controlled by PLC and detected by material level sensor. As it is monitored by photoelectric counter, after setting the number of tablets and blister sheets, the machine will automatically calculate the production capacity.

- It can automatically remove waste aluminum foil and waste capsules (patent protection), and ensure the quality of the capsules and tablets that are removed.

- It accords with the process quality standard of Chinese Pharmacopoeia 2015 edition, and the system itself conforms to the latest version of GMP.

- It reduces labor, makes the whole recycling process more standardized and simplified, and greatly improves the production efficiency.

review(s)

Baby machine

Instead of a manual machine, this is an eye-catcher

From: Chius | Date: 3/3/2021 10:01 PM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche