Introduction

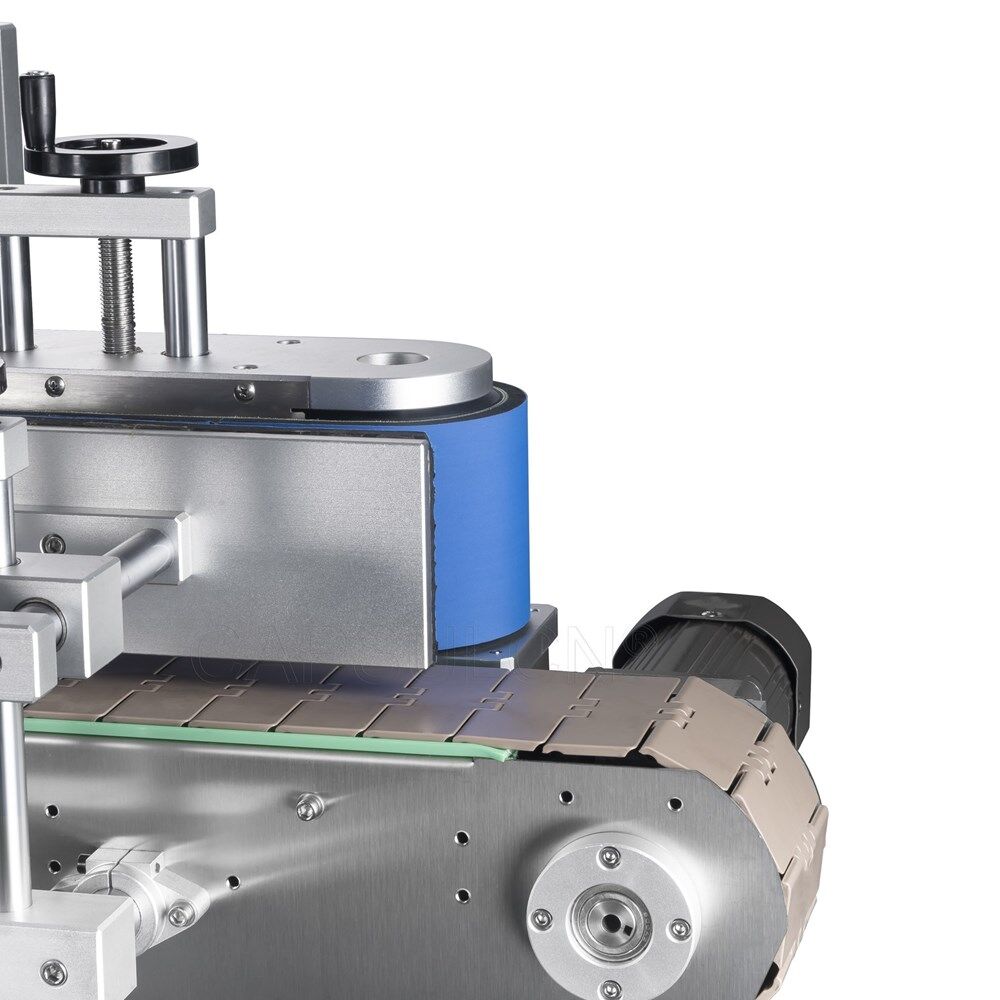

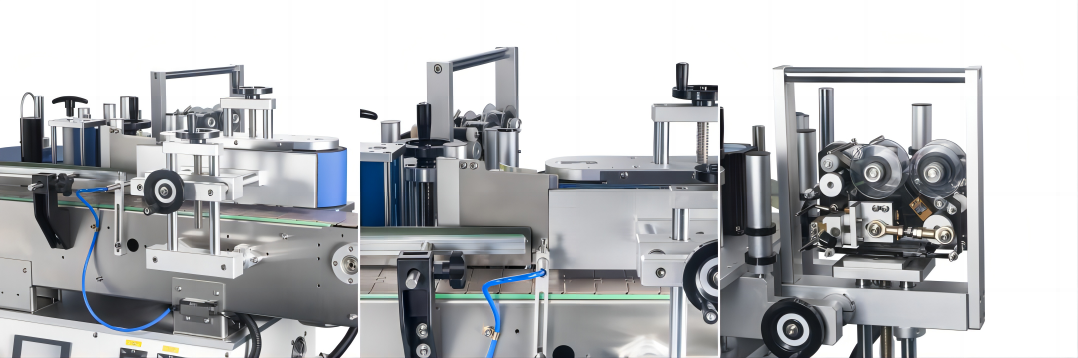

The MPC-10300 is specially designed and specific, and is dedicated to labeling round bottles provided by customers, improving production efficiency. It is suitable for products that require labels to be attached to circumferential and conical surfaces, and is widely used in food, medicine, daily chemicals, electronics, hardware, plastics and other industries. Our labeling machines can improve production efficiency and reduce labor costs, making them the best choice for your business.

Specifications

| Model | MPC-10300 |

|---|---|

| Labeling accuracy | ±1mm (excluding product and label errors), the adjustment level obviously affects the labeling accuracy |

| Labeling speed | 20~100 pcs/minute, depending on product length and quality |

| Applicable products | diameter Φ25mm-Φ100mm, height Φ75-300mm |

| Applicable labels | width 25-100mm, length 20-285mm |

| Dimensions | 1200×850×730mm L×W×H |

| Applicable power supply | 220V 50/60Hz |

| Machine weight | about 150kg |

Remarks

-

This labeling machine is specially customized according to the customer's product, not a standard product. It has technical requirements for the operator, and needs a break-in period of about one month. During this period, if the operation of the equipment fails to meet the technical parameters, it needs to be reported to the manufacturer in time to obtain technical support.

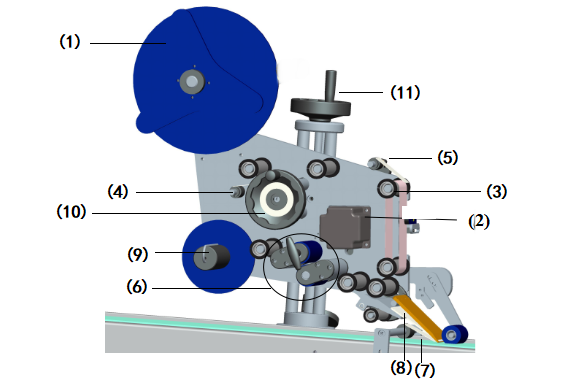

Structure

(1) Loading Tray: used for loading roll labels.

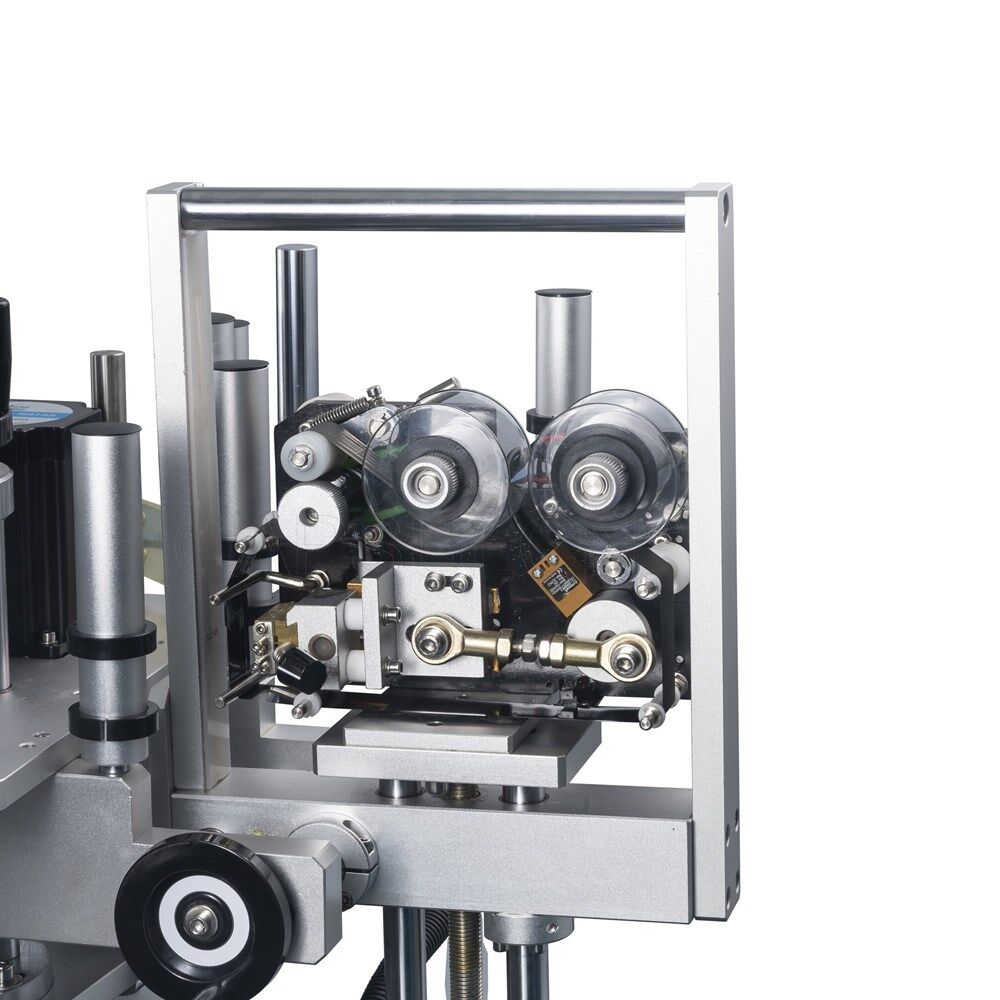

(2) Traction motor: provide power for label stripping.

(3) Rollers: run around the label to ensure the tension of the label.

(4) Label pressing device: press the label tightly to ensure the tension of the label.

(5) Electric eye frame: install the label detecting electric eye, and move the electric eye back and forth.

(6) Traction mechanism: pull the label backing paper, providing power for stripping labels.

(7) Stripping plate: peel off labels.

(8) Pressing mechanism: used to press the label tightly.

(9) Receiving mechanism: recycle label backing paper.

(10) Horizontal adjustment: adjust the left and right positions of the entire sticker head.

(11) Vertical adjustment: used to raise and lower the sticker head as a whole.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Powder Sifter Machine SY Series

Powder Sifter Machine CXZ-Series

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche