Some of the shapes that you can make using the softgel encapsulation machine are:

* Oblong Softgel Capsules

* Round Softgel Capsules

* Tube Softgel Capsules

* Oval Softgel capsules

Introduction

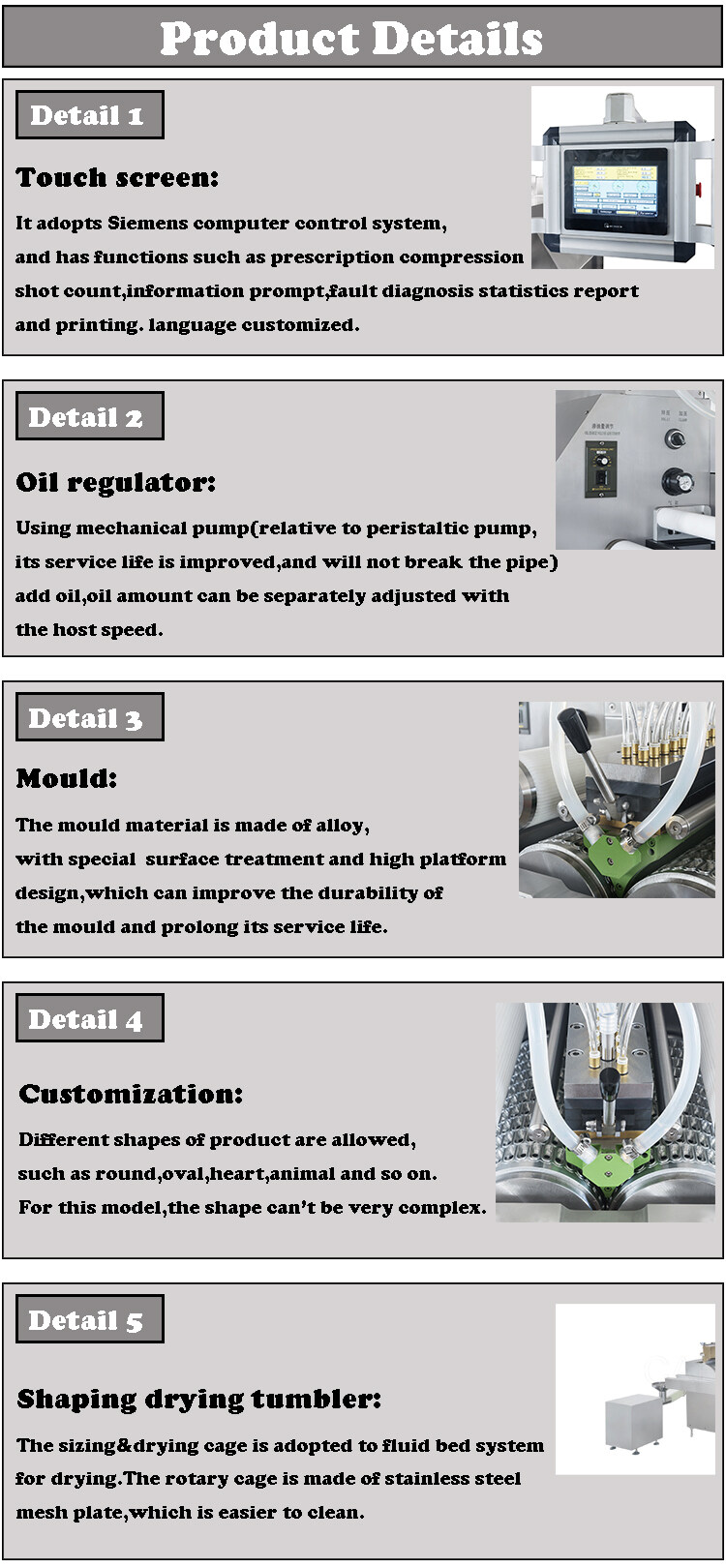

Soft gelatin encapsulation line is suitable for filling a certain amounts of prepared medicine solutions into two lines gelatin sheet and forming soft gelatin capsules or balls with various size, shape and color after compression under the action of one pair opposite movable moulds.

It’s consist of compression system, gelatin melting system, raw material compounding system, shaping and drying system, cleaning system, recycling system etc. During gelatin compression and forming, it can be finalized within the sealed cavity so as to avoid coming across medicine oxygenation.

Specifications

|

Die Roll Capacity In Common Use |

|||||||||||

|

RJWJ-115 |

RJWJ-200 |

RJWJ-300 |

|||||||||

|

Shape |

Model |

Mould cavity |

Capacity of the medium speed(Pill/Hour) |

Shape |

Model |

Mould cavity |

Capacity of the medium speed(Pill/Hour) |

Shape |

Model |

Mould cavity |

Capacity of the medium speed(Pill/Hour) |

|

Oval |

4 |

114 |

17100 |

Oval |

4 |

286 |

51480 |

Oval |

4 |

714 |

85680 |

|

8 |

85 |

12750 |

8 |

230 |

41400 |

8 |

585 |

70200 |

|||

|

20 |

52 |

7800 |

20 |

140 |

25200 |

20 |

334 |

40080 |

|||

|

Oblong |

4 |

86 |

12900 |

Oblong |

4 |

236 |

41400 |

Oblong |

4 |

554 |

66480 |

|

8 |

64 |

9600 |

8 |

206 |

37080 |

8 |

468 |

56160 |

|||

|

20 |

48 |

7200 |

20 |

138 |

24840 |

20 |

315 |

37800 |

|||

|

Round |

8 |

82 |

12450 |

Round |

8 |

231 |

41580 |

Round |

8 |

590 |

70800 |

Remark

- Strong product capacity, it can produce 300 million granules (No.8 oval shape, 3 revolutions/minute, 24 hours / day, 300 days/year).

- Injecting medicine part adopts advanced linearity driving system, and it makes sure that the precision of

charging and filling is less than 2%. Capsule package rate is up to 98%. - The gelatin ribbon is lubricated by fine oil supply technology in order to lower the consumption of

lubrication oil. The ribbon is lubricated by vegetable oil, so the capsules produced is free of wash. - High quality capsule deferent equipment adopts food conveyer belt authorized by American FDA, without

poison and adhibition and easy to clean. - Optimized designed mould is made of high quality aviation alloy material by high precision numerical

control process to insure the mould's service life.

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche