Video

Introduction

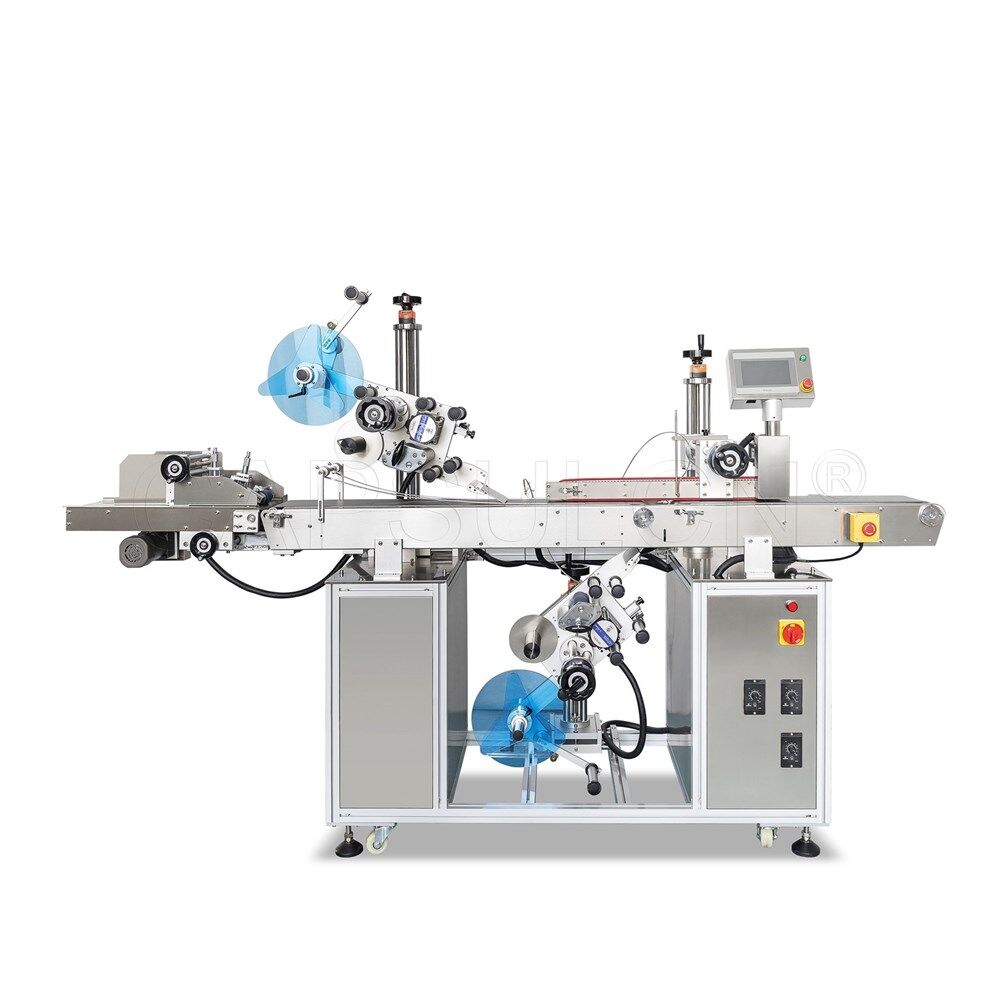

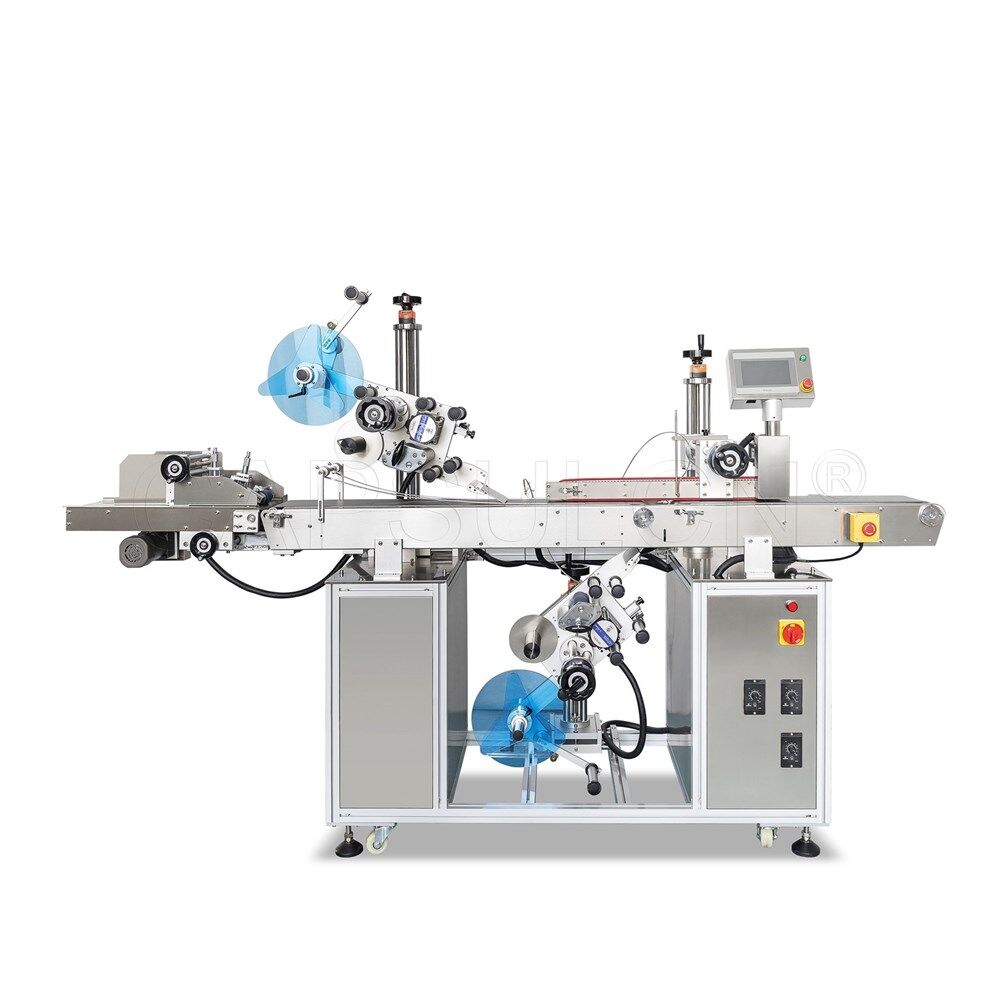

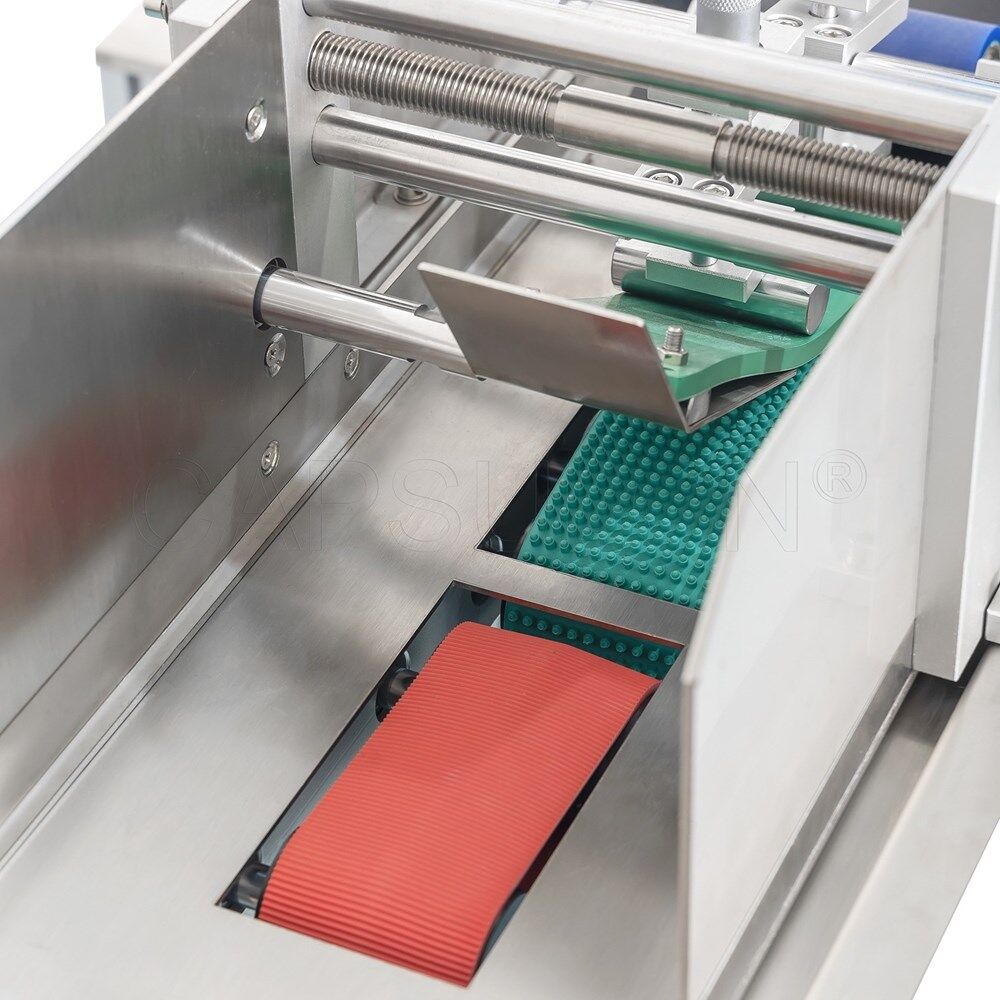

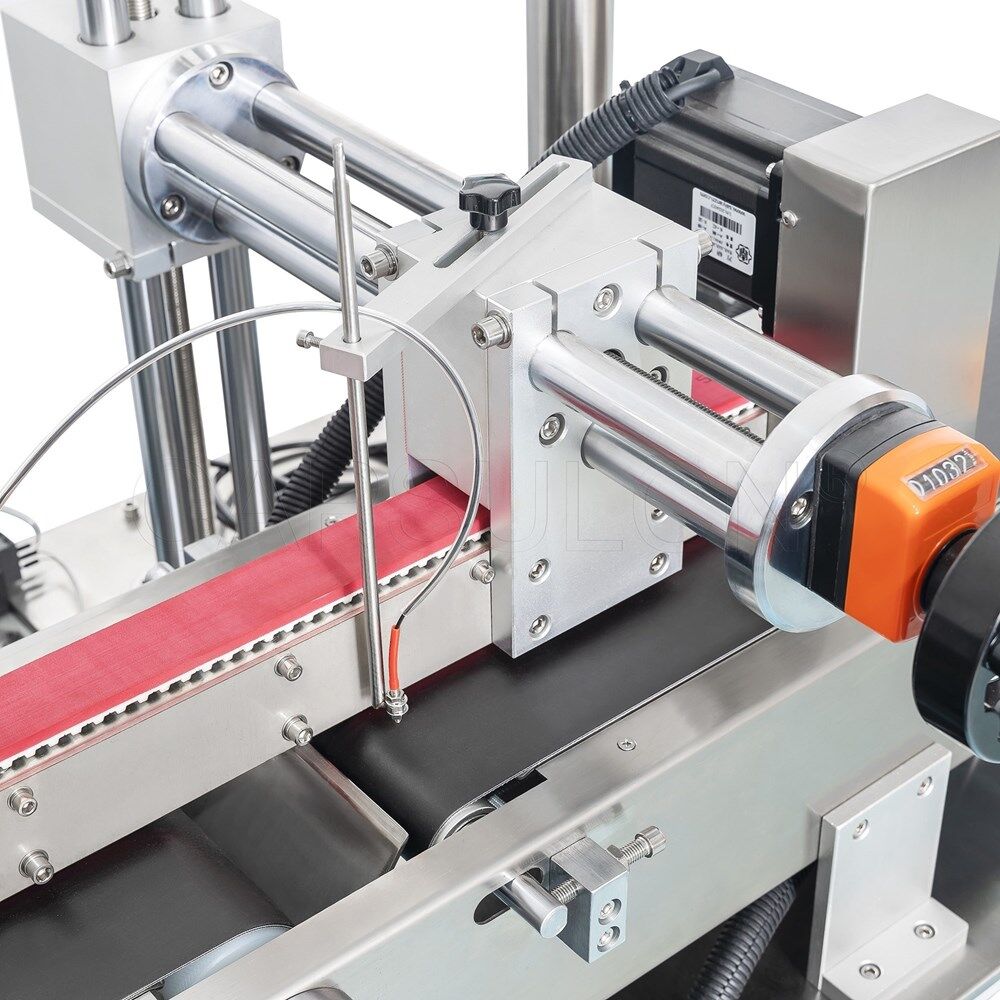

The CTB-3600 double-head flat label machine stands out in the flat label pasting field with its excellent performance and design. The double-head design enables simultaneous pasting of double-sided labels, significantly improving production efficiency; high-precision label pasting ensures product quality and meets strict production requirements. In addition, the features of easy operation and maintenance reduce usage costs and improve equipment utilization. Choose CTB-3600 and you will get an efficient, reliable and economical flat label solution.

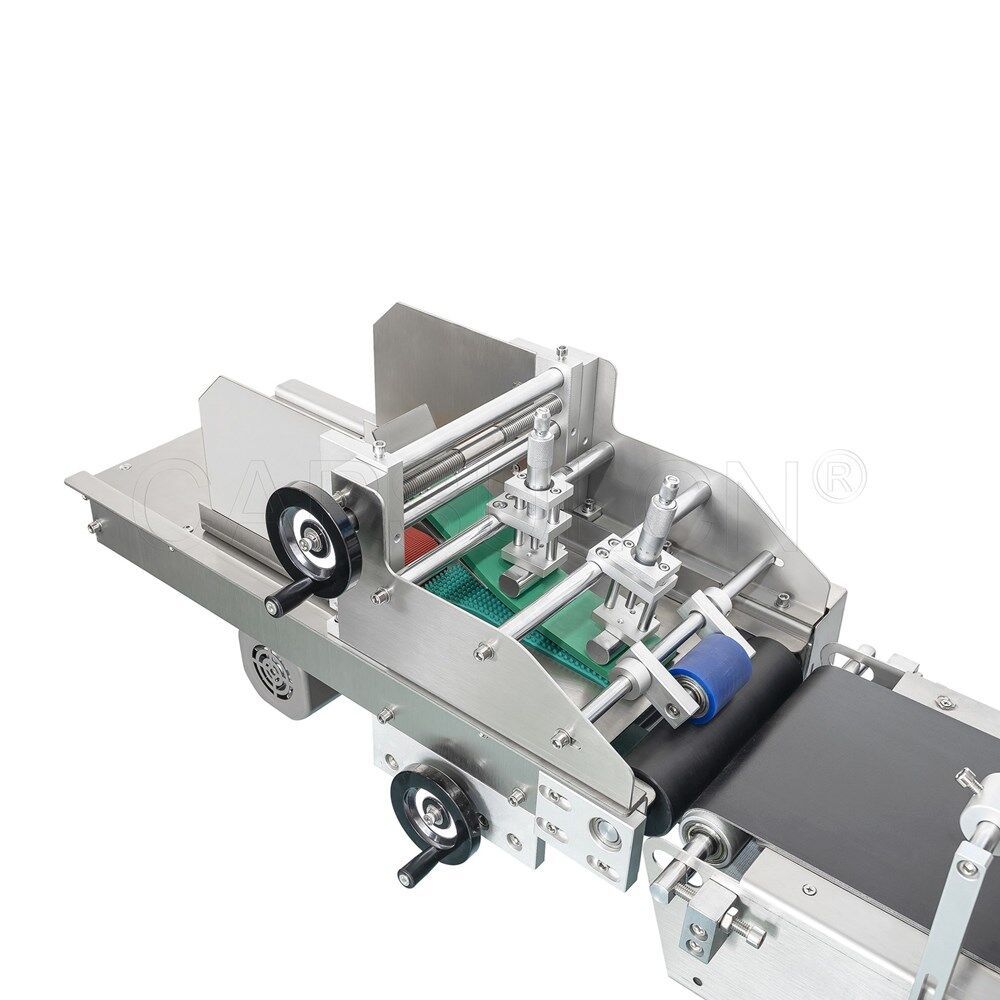

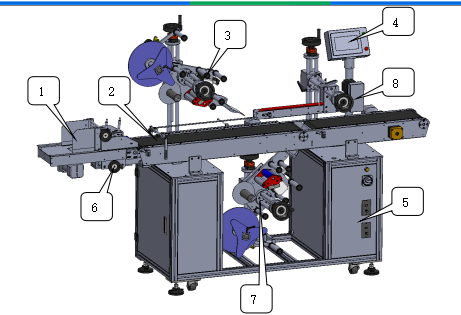

| 1. Separation card mechanism | 2.Transportation mechanism | 3.Labeling head1 | 4.Human-machine interface |

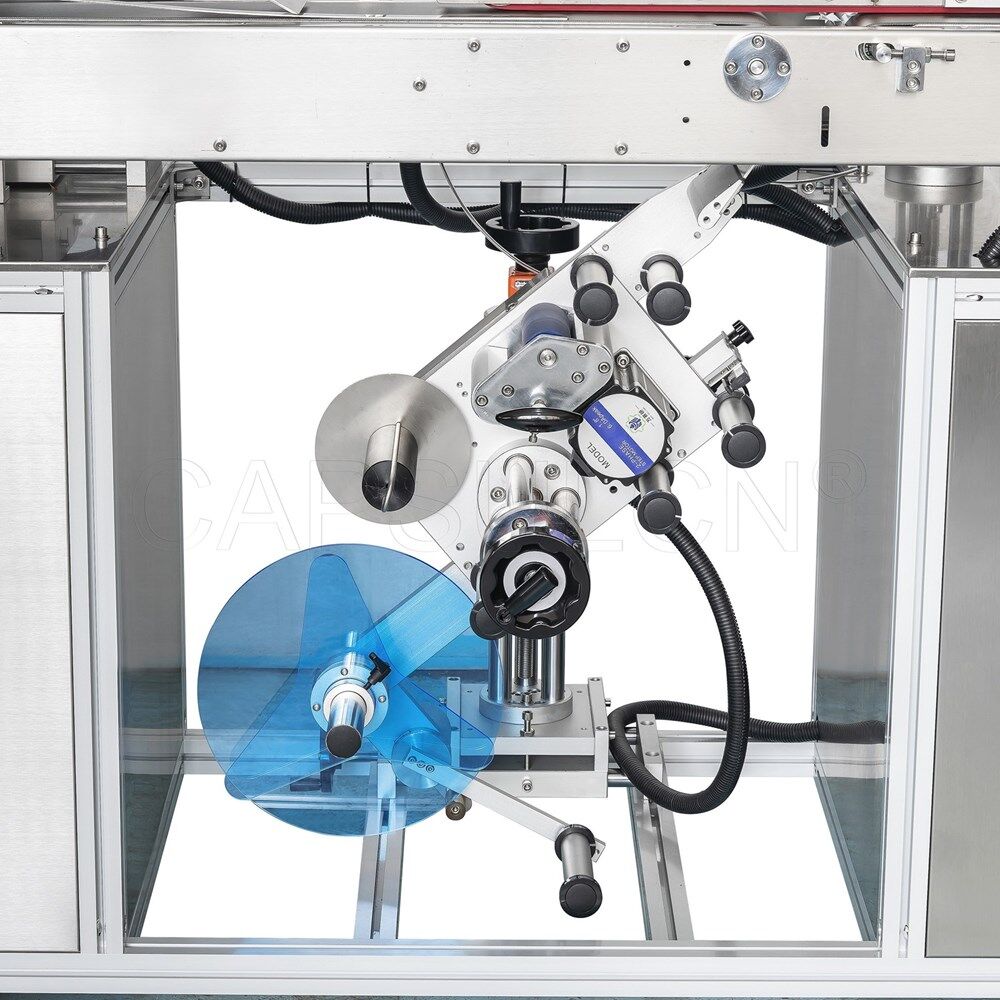

| 5.Electrical control box | 6.Separation card mechanism adjustment | 7.Labeling head2 | 8.Pressure top mechanism |

Feature

- Double-head design: equipped with two label heads, double-sided label pasting can be performed at the same time to improve efficiency.

- High precision: label pasting accuracy can reach ±1mm, ensuring the label position is accurate.

- High efficiency: label pasting speed can reach 20~80 pcs/min to meet different production needs.

- Wide range of applications: can be applied to the pasting of various flat labels, such as card labels, bottle cap labels, plastic labels, etc.

- Easy operation: friendly human-machine interface, simple and easy to learn operation.

- Easy maintenance: simple structure, easy maintenance, and reduced maintenance costs.

.png)

Specifications

| Model | CTB-3600 |

|---|---|

| Labeling precision | ±1mm (Errors of products and labels are not included.) and adjustment level will influence labeling precision obviously |

| Labeling speed | 20~80 pcs/min. Depending on product length and quality. |

| Applicable product | samples provided by the customer. |

| Applicable label | rolled label provided by the customer. |

| Machine dimension | 2270×750×1360mm (Length×Width×Height). |

| Applicable power | 220ACV 50/60Hz |

| Machine weight | 165kg |

Remarks

-

This labeling machine is specially made according to the customer's product, not a standard product, and has technical and experience requirements for the operator, and requires a running-in period of about one month. During the running-in period, if the operation of the equipment does not meet the technical parameters, it is necessary to report it to the manufacturer in time to obtain technical support.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Automatic Continuous Mill Herb Grinder WF Series

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche