Introduction

The CDR-3A orbital electronic grain counting machine is an automated equipment with high efficiency, high precision and high reliability. The equipment adopts American ARM chip microelectronic control and Japanese SMC and American MAC high-speed solenoid valves, which has stability and durability. At the same time, the equipment adopts an integrated integrated design circuit, which is easy to maintain, has simple wiring and is easy to use.

working principle

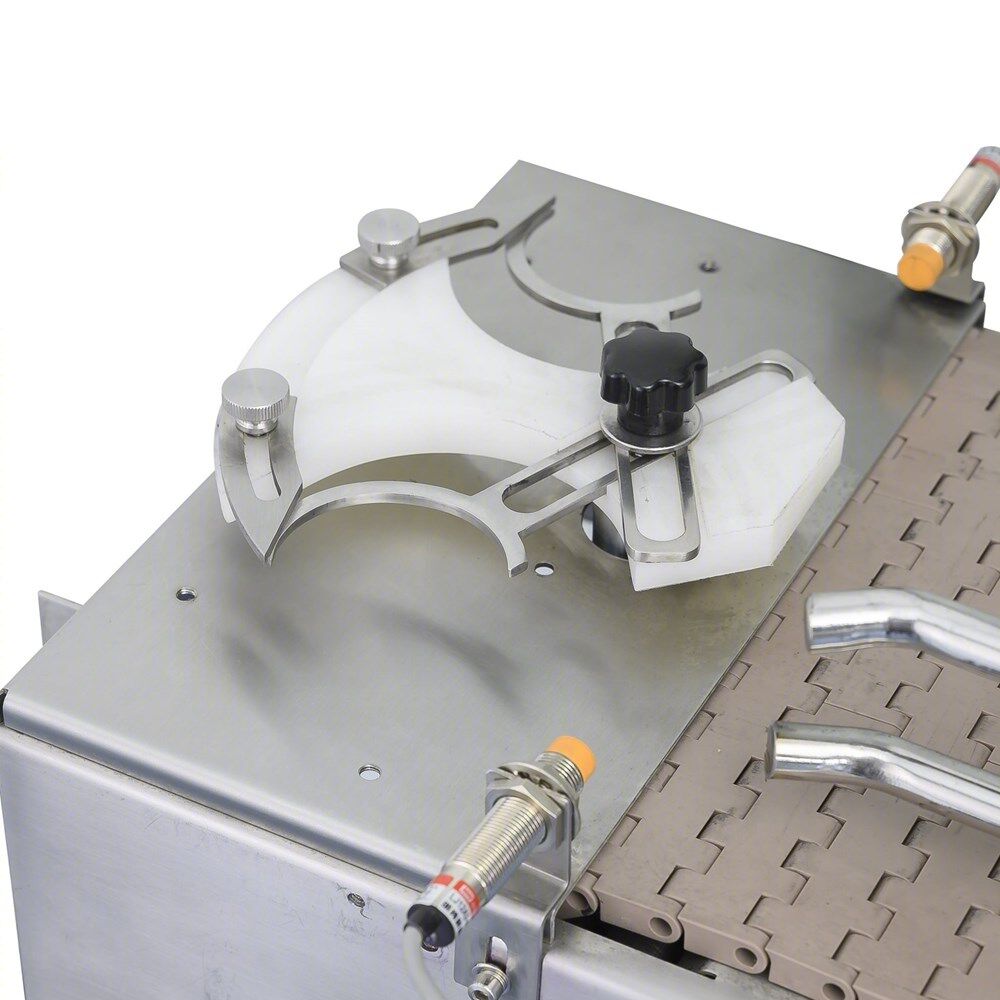

the empty bottles are transported to the track through the bottle dividing plate, and the track transports the empty bottles to the unloading port, waiting for the material to be bottled. The material slowly enters the glass discharging tray through the discharging track, and the glass The rotation of the discharge plate forms a corresponding centrifugal force, and then through the pre-adjusted track bar, the objects to be measured are lined up in sequence, and enter the object sensor for counting processing. After the counting is completed, it falls into the empty bottle through the discharge port, and waits for After the number of falling grains reaches the set value, the falling material limiter pops open, and the loaded bottle material is transported to the next link through the track!

Main features:

- Using American ARM chip microelectronic control, it has high efficiency and high precision.

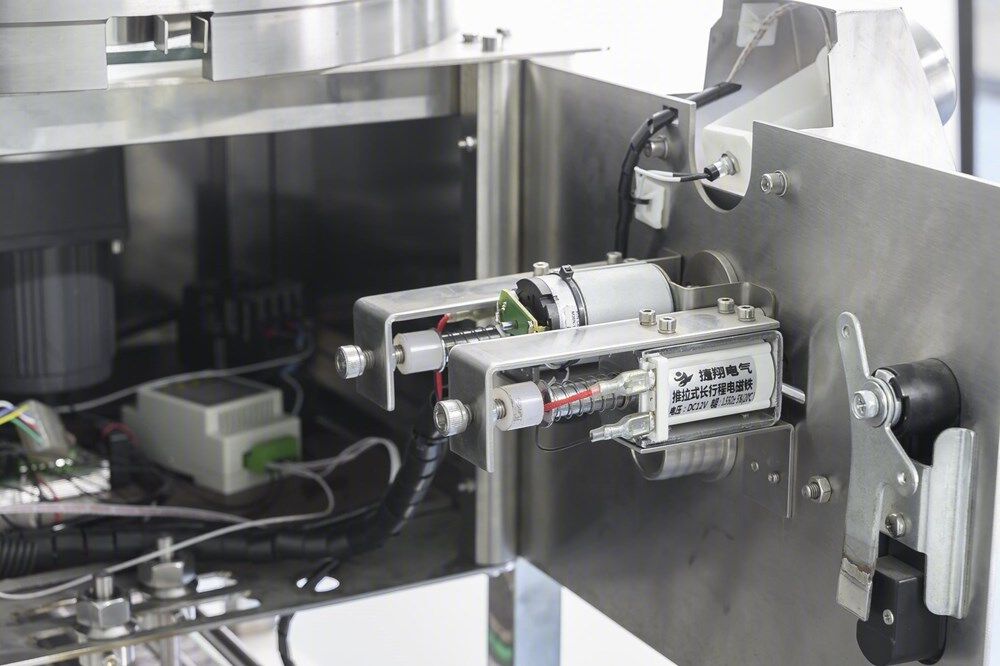

- The pneumatic components adopt Japanese SMC and American MAC high-speed solenoid valves, which are stable and durable.

- The program scan time and I/O response time both reach the nanosecond level, and the interrupt module timing time unit is 0.02ms, which can meet the grain counting speed of 1,300 grains per minute.

- One-piece integrated design circuit, easy maintenance, simple wiring and easy to use.

- Equipped with an original orbital feeding structure, it has the superior performance of stability, low noise, and smooth delivery of medicine particles.

- The silicone material is used to ensure the safety of the contact surface with the material, and avoids the shortcomings of tablet damage caused by traditional vibrating discharging, ensuring the integrity of the measured object and ensuring the accuracy of counting tablets.

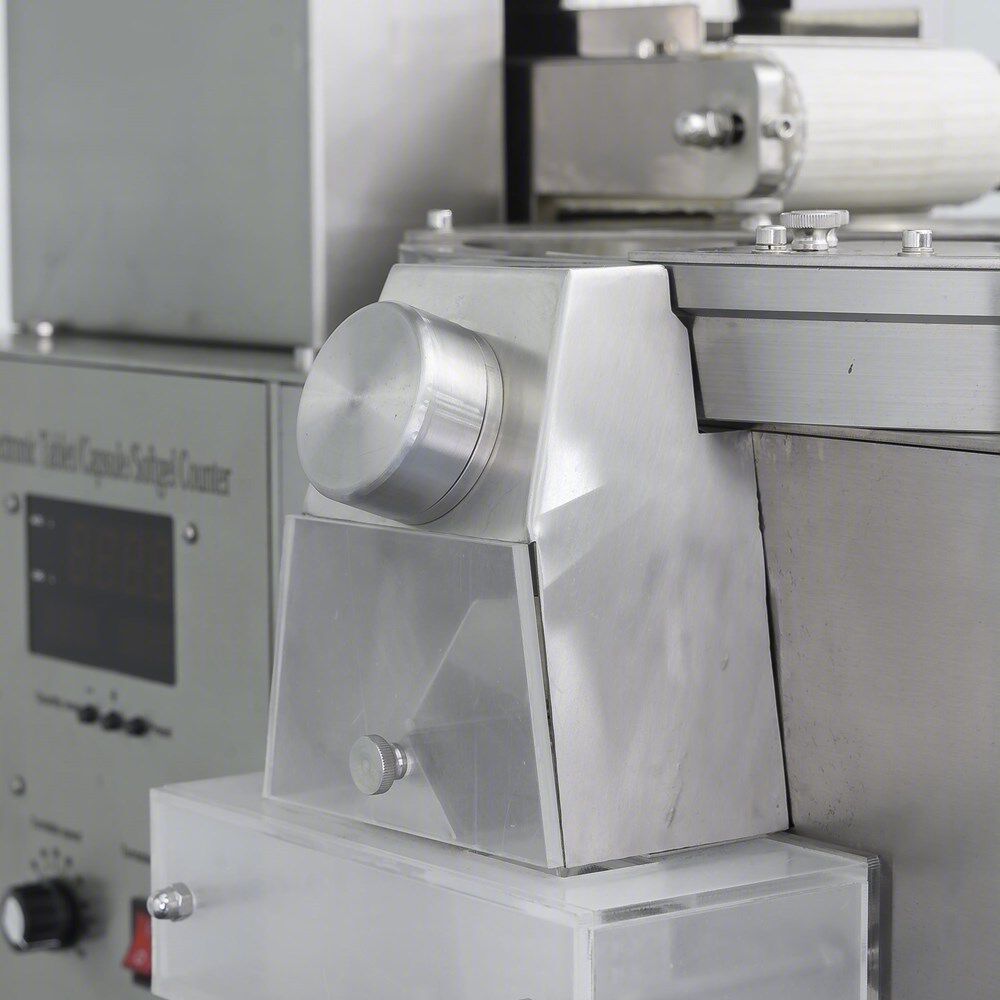

- It adopts a self-designed combined photoelectric particle counting device. The main electronic components of the photoelectric are imported from Japan. It has high sensitivity, high response speed, high dust resistance, and stable detection and output signals.

- A small gate slitting device is used. The device adopts an integrated structure design. The accessories use solenoid valves and Japanese SMC cylinders. The cylinders and solenoid valves use unique self-designed connecting blocks to eliminate air leakage and ensure the stability of the equipment to the greatest extent. and reliability.

Specifications

| Model | CDR-3A |

|---|---|

| Production Capacity | 1300 capsules/min (data source is Capsule No. 0) |

| Grain counting accuracy | 99.99% |

| Quantity per bottle | 1-9999 can be set as desired |

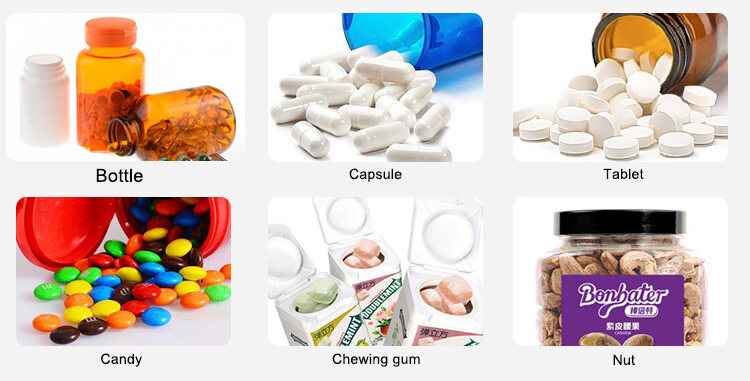

| Applicable pharmaceutical range | Tablet: Maximum φ22mm; Capsule #00-#5 |

| Applicable bottle mouth size | kwφ20~25mm (can be customized according to customer requirements) |

| Power Specifications | 220V AC, 50/60 Hz |

| Power consumption | 0.2kW |

| Air consumption (m3/h) | 0.1 |

| Air pressure (MPa) | 0.4 |

| weight | |

| External dimensions (mm) (Length × Width × Height) | 845*1372*1648mm |

Remarks

- First determine whether the power supply marked on the machine meets the order requirements.

- The power socket should have a safety grounding wire, and there should be no high-brightness spotlights irradiating the machine indoors. If there is excessive dust on the material being tested, please bring your own vacuum equipment to connect to the vacuum port of the counting machine.

- After the equipment is installed, adjust the column fixing feet to make the equipment stable.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche