Introduction

The CNF-80A Automatic Tube Filling and Sealing Machine is designed for filling and sealing plastic tubes, composite tubes, and aluminum-plastic tubes. It boasts a production speed of 50-80 tubes per minute, a filling range of 3-250 ml per tube, and a filling accuracy of ≤±1%. The machine features a compact structure, compliance with pharmaceutical machinery industry standards, and components made of high-quality materials like stainless steel and 316L stainless steel. It is suitable for industries such as pharmaceuticals, food, and daily chemicals.

Specifications

| Model | CNF-80A |

|---|---|

| Production Speed | 50-80 tubes/min |

| Filling Range | 3-250 mL/tube |

| Filling Accuracy | ≤±1% |

| Room Temperature | 18-26℃ |

| Matching Motor | 1.5 kW |

| Dimensions | 2.4×1.1×2.4 (m) |

| Weight | 1500 kg |

| Working Air Pressure | 0.5-0.7MPa |

Feature

- To avoid contamination and facilitate cleaning, the surface of the machine is made of stainless steel and steel (non-toxic nickel plating).

- Parts directly in contact with materials are made of 316L stainless steel, corrosion-resistant, weakly acidic, and weakly alkaline.

- The body of the machine is made of high-quality steel.

- High-quality products are selected for the machine's connecting components.

- No filling without tubes.

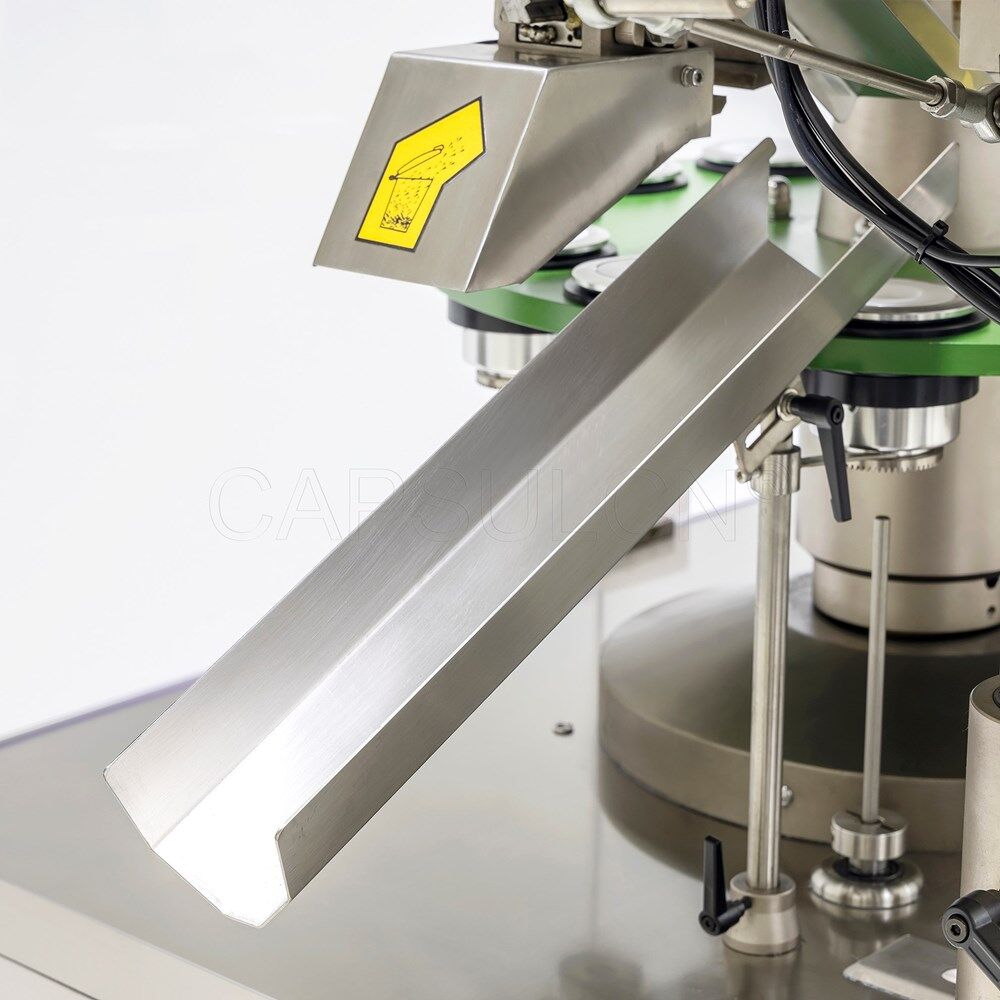

- Automatic batch coding, automatic tube ejection.

- Automatic tube feeding and automatic color mark alignment.

- Automatic filling with tail-cutting function for viscous materials.

Rmark

- Adequate power supply and air pressure must be maintained for optimal performance.

- Safety features such as emergency stop buttons, door interlock devices, and overload limit devices should be understood and utilized correctly.

- Proper adjustment of various components like the tube slot, filling nozzle, and measurement piston is crucial for efficient operation.

- Regular maintenance and cleaning of components like the material barrel, injection port, filling valve, and plunger are necessary for machine longevity and performance.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche