Introduction

The pump body of the water pump is made of various imported materials that are anti-corrosive. It is separated with motor and there are no mechanical metal parts in it. Of course, it has no sign of wear. It is with oil resistance, heat resistance, acid resistance, alkali resistance, corrosion resistance, chemical resistance and other properties. This water pump combines the advantages of self-priming pump and chemical pump, such as self-priming function, thermal protection, stable operation, continuous idling for a long time, and continuous load operation for a long time.

Feature

- Controlled by imported single-chip microcomputer, it has high efficiency and low power consumption.

- It has automatic counter which ensures how many bottles to be filled.

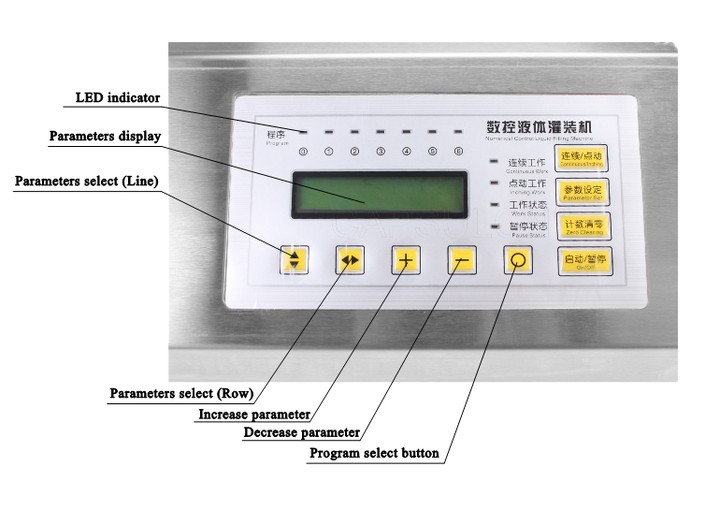

- It is easy to operate with liquid-crystal display (LCD).

- It is designed well with high filling precision and accurate measurement. Wide voltage range. Stable product performance and long service life. With self-priming function, no need to pour back when starting up. The discharge nozzle is well-designed to prevent dripping. The pump body is resistant to acid and alkali.

- Safe and hygienic——stainless steel shell, with anti-corrosion, wear-resistant and other characteristics

- Anti-leakage design of the discharge nozzle - using the anti-drip check valve filling head, dripping is prevented and the operation is convenient.

Specifications

| Model | GFK-160 |

|---|---|

| Power supply | AC180V-260V |

| Power | 30W |

| Range of filling | 2-3500mL |

| Repeatability error | <0.5% |

| Maximum filling capacity | 3.2L/min |

| Maximum pump suction lift | 2m |

| Aiti-dripping function | yes |

| Power failure memory function | yes |

| Production capacity | 10-40 bottles/min |

| Overall dimension (L*W*H) | 345*340*145mm |

| Weight | 4kg |

| Package Weight | 4.5kg |

| Package Size (L*W*H) | 400*365*174mm |

Remarks

-

The environment requirement: room temperature, environment with high temperature, humidity, acid and alkali is not advised to be used for a long time, so as not to affect the service life, efficiency and accuracy of fillings.

-

Take a careful look at whether there are impurities in the small filter, feeding nozzle and discharging nozzle.

-

Check whether power supply is good, and power line are in good condition.

-

The machine should be well grounded.

-

Running the machine for testing first to find whether something abnormal is happening.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche