Introduction

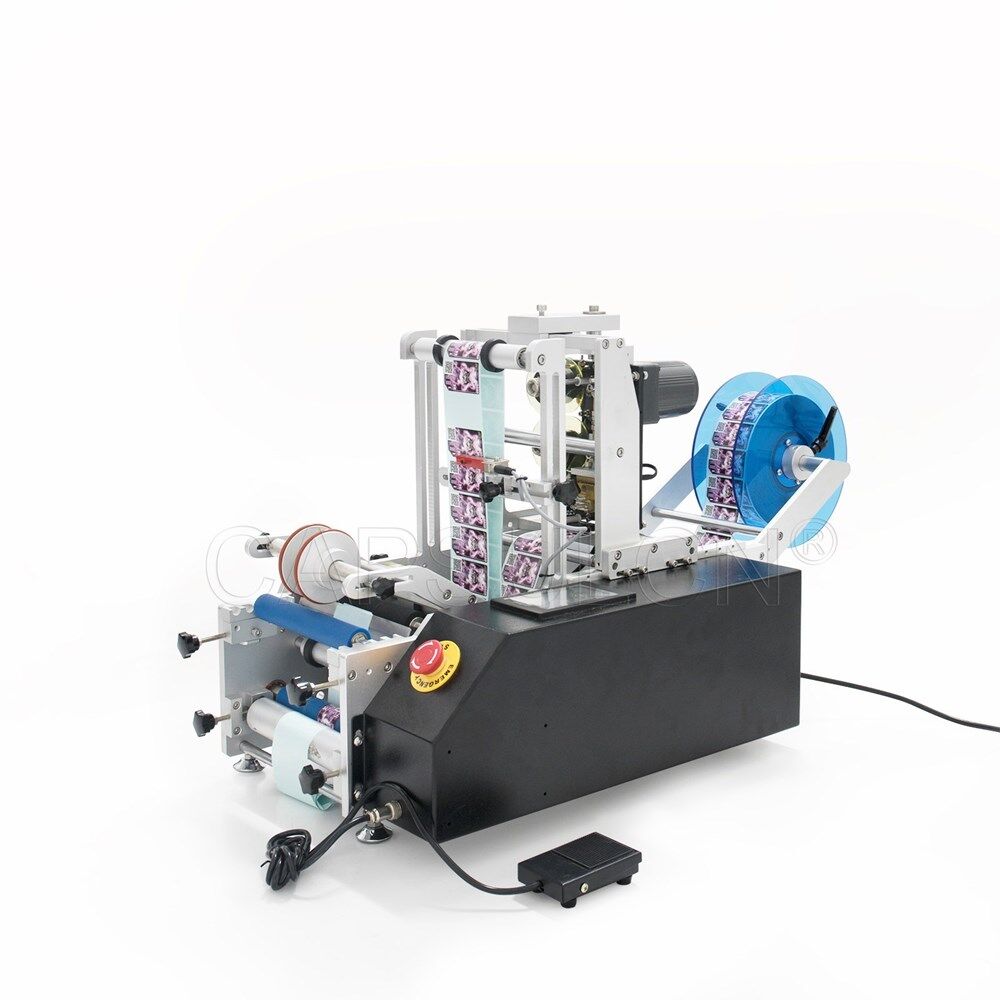

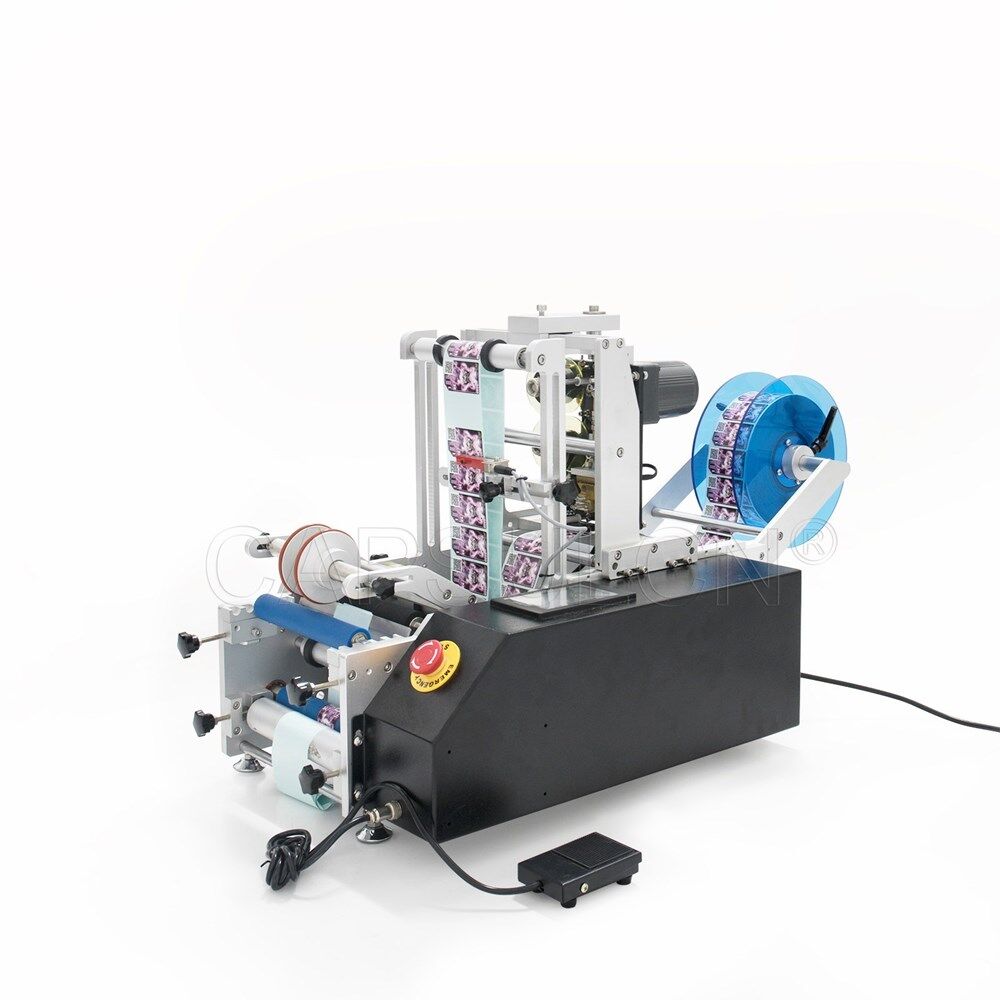

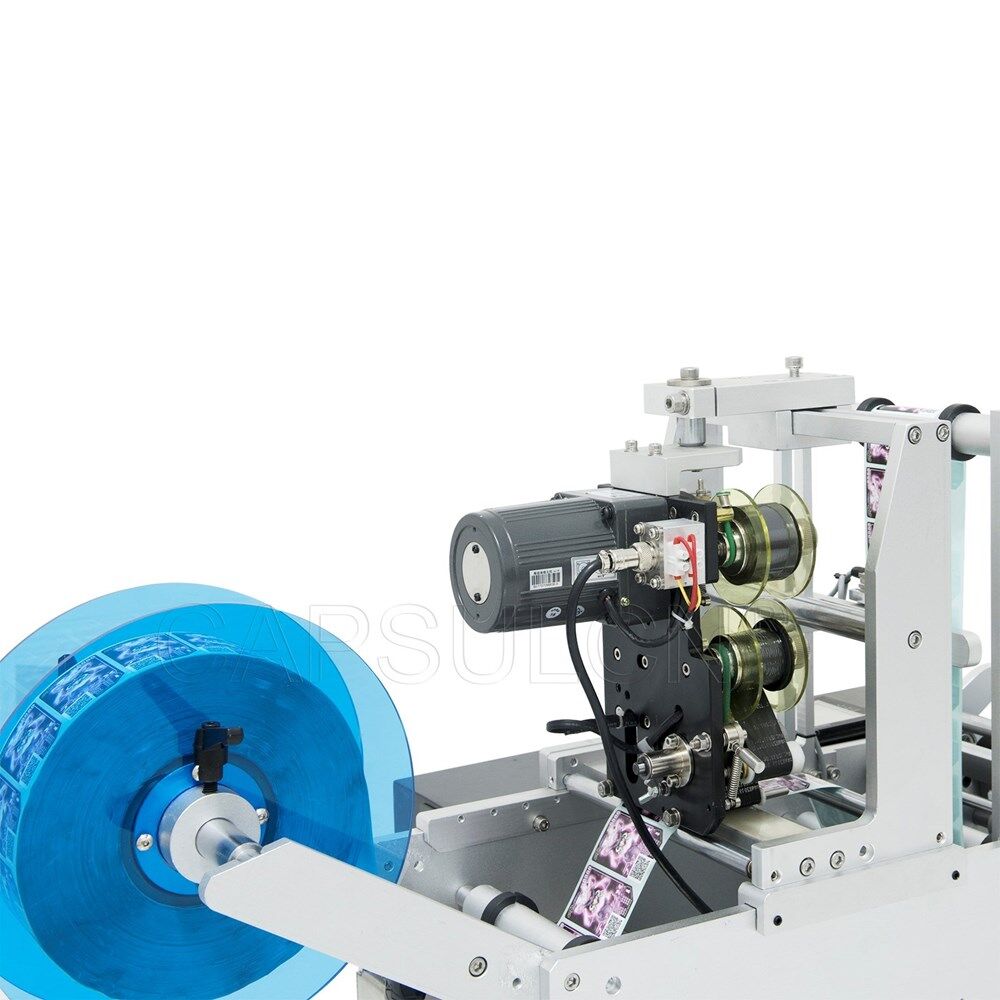

The T-41311 semi-automatic round bottle labeling machine can also be equipped with a ribbon coder and an inkjet printer to achieve labeling and print production batch numbers and other information at the same time, improving production efficiency. The applicable labels for our products include self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc., which can meet the labeling needs of different industries.

It is suitable for products that require labels to be attached to circumferential and conical surfaces, and is widely used in food, medicine, daily chemicals, electronics, hardware, plastics and other industries. For example, our products can be used in application examples such as oral liquid round bottle labeling, vial labeling, xylitol labeling, shampoo bottle labeling, and small taper cosmetic bottle labeling.

Our labeling machines can improve production efficiency and reduce labor costs, making them the best choice for your business.

.png)

Specifications

| Model | T41311 |

|---|---|

| Labeling accuracy | ±0.5mm (excluding product and label errors) |

| Labeling speed | 10~30 pieces/minute (theoretical value, related to product, label size and operation level) |

| Applicable product size (mm) | Φ15≤diameter≤Φ150 |

| Applicable label size (mm) | 10≤width≤180 15≤length≤376 |

| Overall machine size (mm) | 920*420*500 |

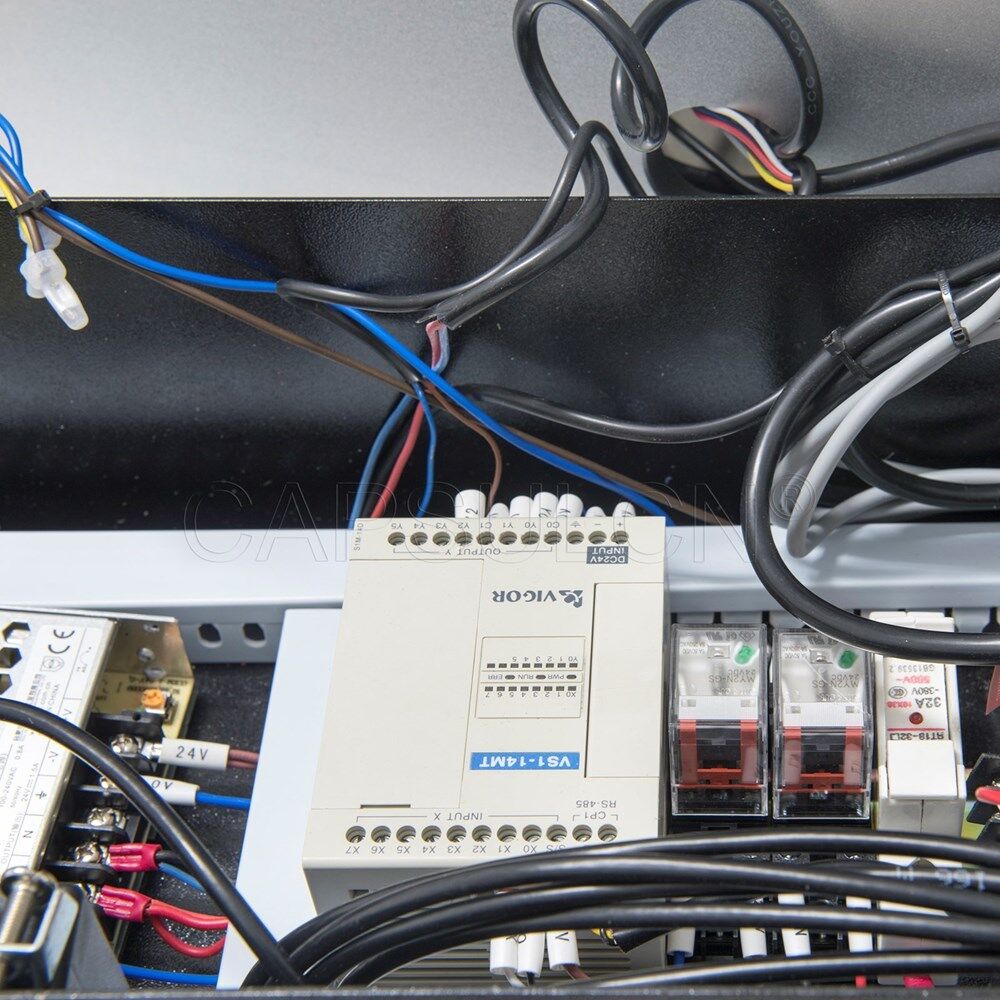

| Applicable power supply | 220V 50/60Hz |

| Machine weight (kg) | 35 |

Remarks

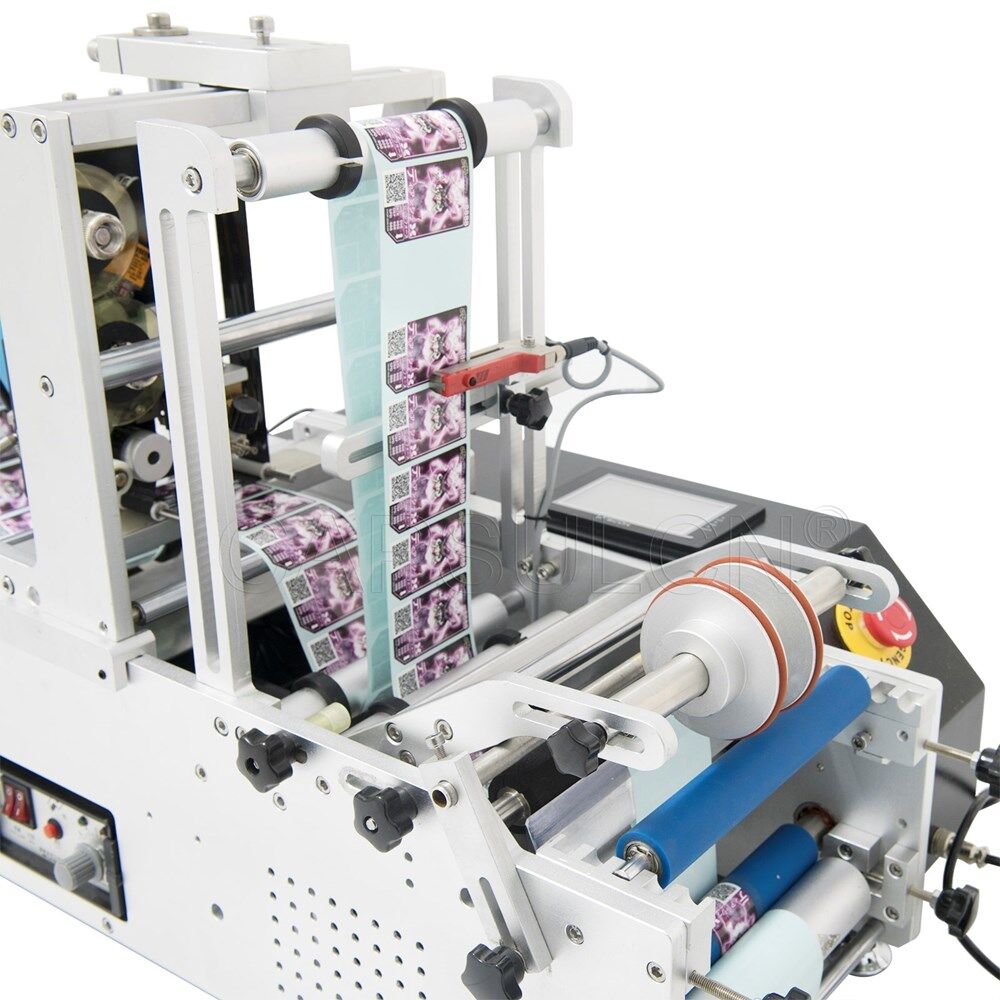

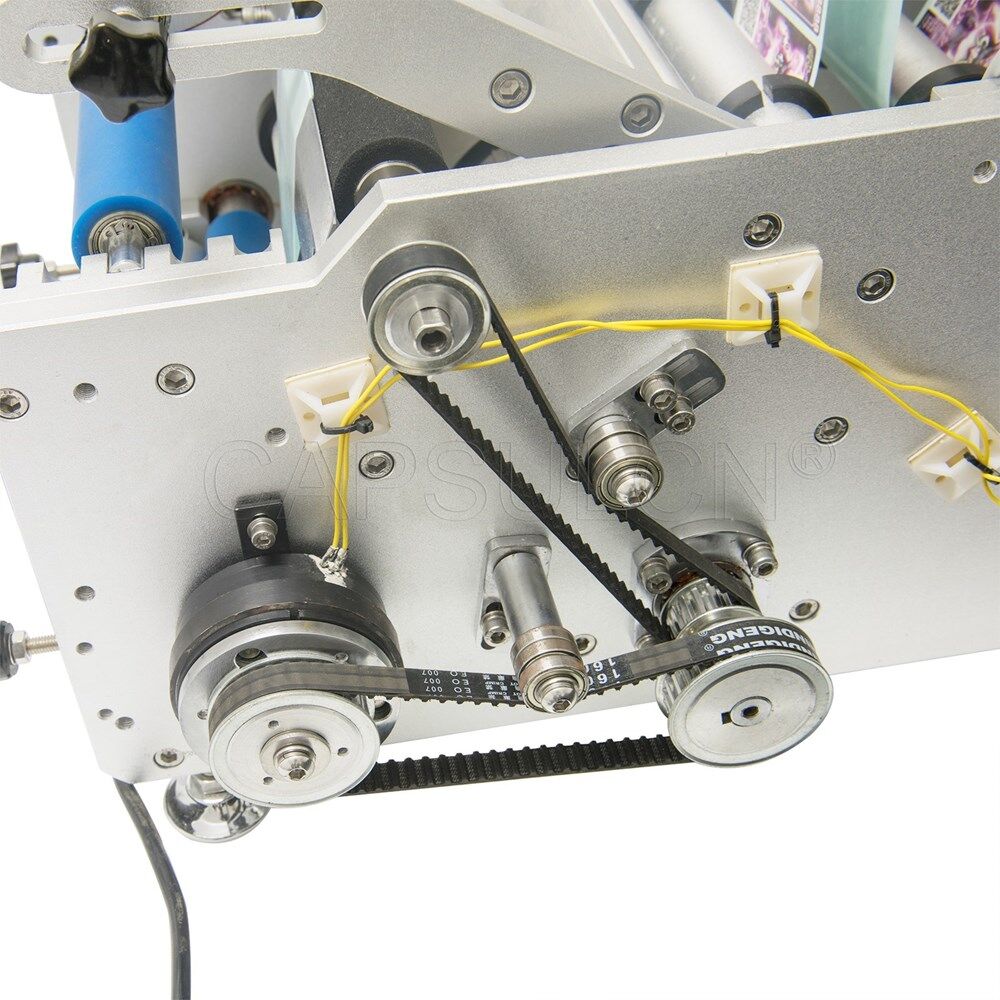

- After the label is wound, switch to the manual state. Please confirm that the power is on and the speed regulator is on. Then press the "jog" switch and let the traction pull the bottom paper forward about 0.5 meters. The purpose is to make the bottom paper Free to correct.

- After the bottom paper is automatically corrected, we can adjust the limit rings on all rollers and move the limit rings to both sides of the bottom paper. When replacing the label in the future, just place the label directly inside the limit ring. When replacing labels with different widths, generally only the limit ring on the right side is moved, and the other side is used as the reference surface. It is generally recommended not to move it.

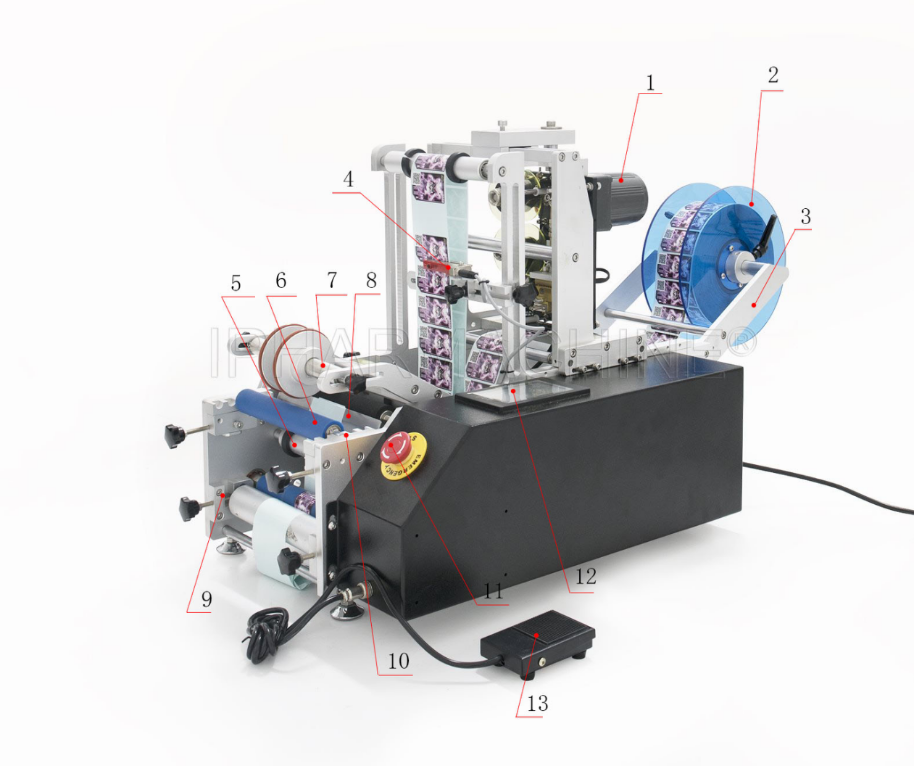

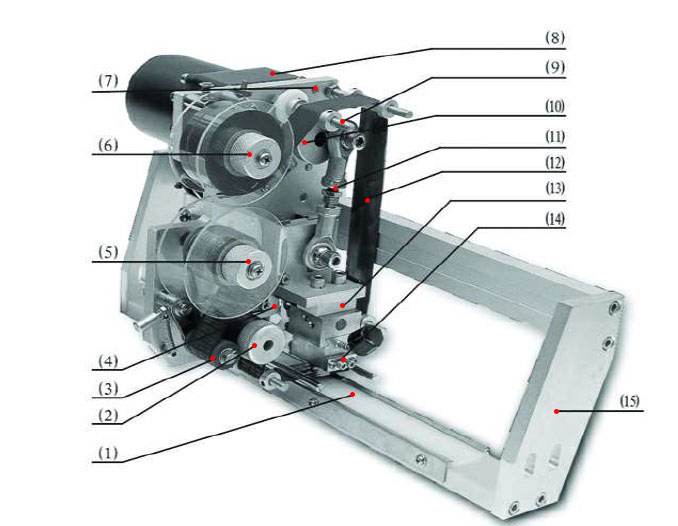

Structure

| 1.Coding machine | 2.Roller | 3.Material rack | 4.Marking electric eye holder |

| 5.Speed regulator | 6.Label covering wheel | 7.Pressing mechanism | 8.Stripping plate |

| 9.Traction mechanism | 10.Bottle holding device | 11.Emergency stop switch | 12.Touch screen |

| 15. Speed regulator switch | 16. Power interface | 17. Power switch |

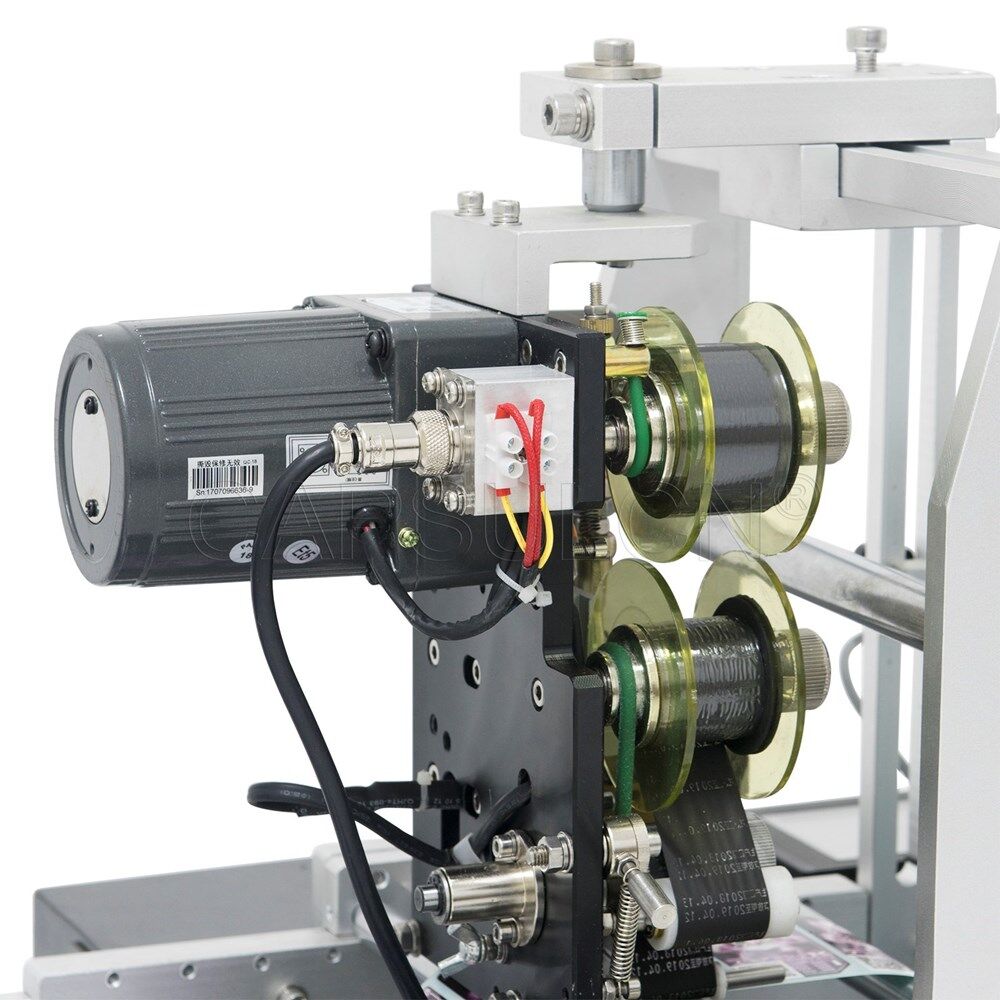

| 1.Typing silicone | 2.Pressing wheel | 3.Silicone component |

| 4.Belt feed adjustment plate | 5.Tape take-up device | 6.Tape release device |

| 7.Belt tension adjustment bolt | 8.Motor | 9.Belt guide connecting rod |

| 10. Driving wheel | 11. Pressure adjusting lever | 12. Carbon belt |

| 13. Printing base | 14. Character slot | 15. Installation plate |

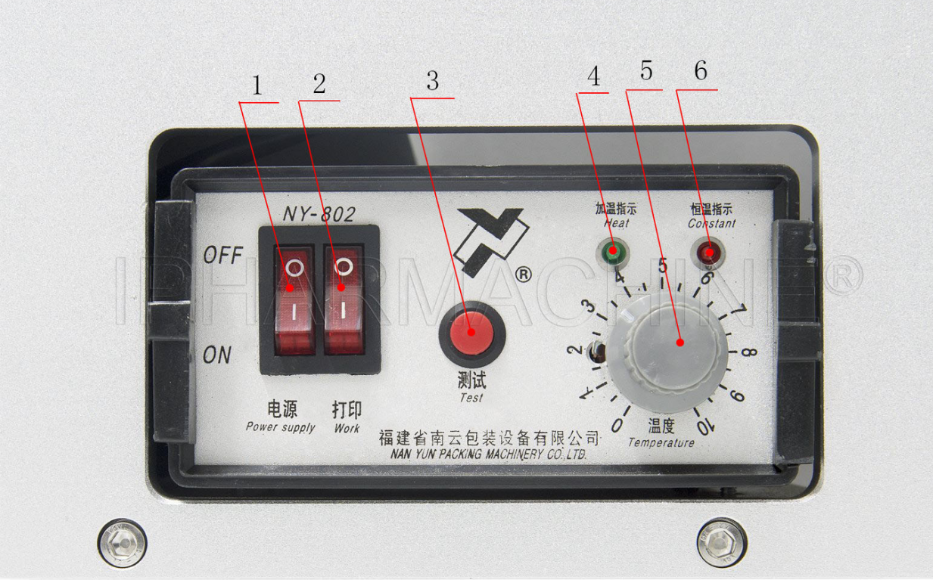

| 1.Power switch | 2.Print switch | 3.Test switch |

| 4.Heating indicator light | 5.Temperature adjustment knob | 6.Constant temperature indicator light |

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Powder Sifter Machine SY Series

Powder Sifter Machine CXZ-Series

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche