Introduction

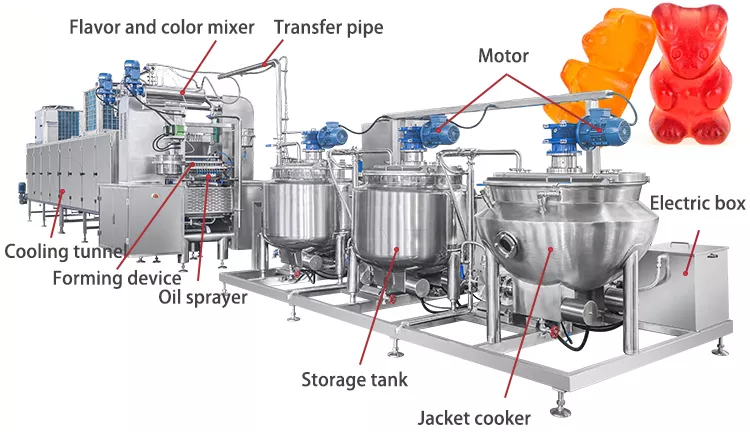

Cooking system——Depositing machine——Cooling tunnel——Molds

1.Cooking system

(1) Dissolving tank with electricity

The device is electrically heated. The vertical jacketed tank has side stirring to prevent the materials from sinking to the bottom. Temperatures can reach 150°C. This production line is mainly used for sufficient dissolution of raw materials.

(2) Cooling tank with electricity

The equipment is electrically heated.

(3) Storage tank with electricity

The device is electrically heated. The storage tank has side stirring to prevent the materials from sinking to the bottom. The temperature of the storage tank can reach 150°C.

2.Depositing machine

The depositing machine is made of 304 stainless steel, which is healthy and safe. The operation is simple and convenient.

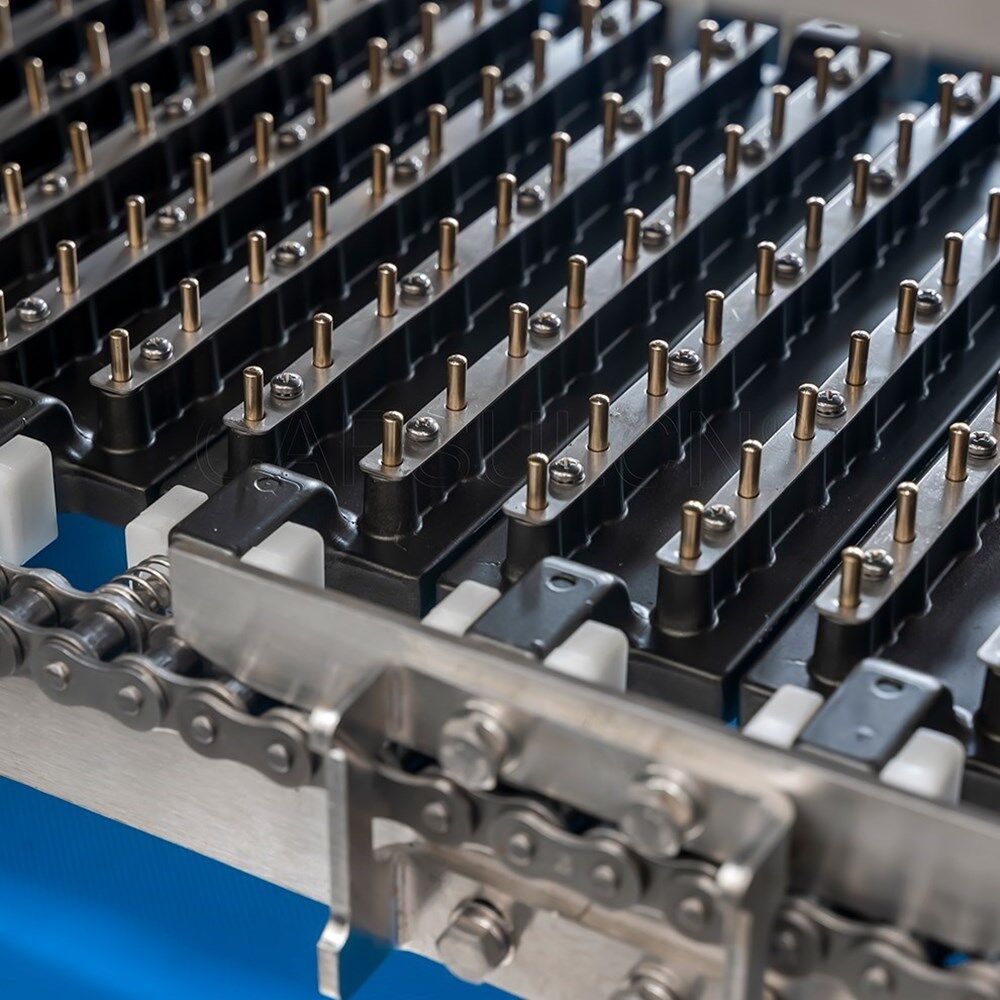

Our chain is stainless steel with surface hardening treatment, easy clean and run smooth.

High accuracy fabrication technology for deposit piston and copper sleeves makes the consistency of candy weight.

The equipment has functions such as oil spray, brush, and air blowing, which helps to better release the candy from the mold.

3.Cooling tunnel

The device is air-cooled and comes with a brush and air blowing function to aid in mold release.

The defrosting and dehumidification settings can be set according to the needs. If the temperature needs to be controlled below 15 degrees Celsius, the demoulding will be smoother. Open the conveyor belt in advance before making candy.

Mould (shape can be customized)

Placed candy molds on a conveyor belt for depositing.

.jpg)

Main Application

Candy shape can be customized.

Specifications

| Model | GD-80 | GD-150 | GD-300 | GD-600 |

|---|---|---|---|---|

| Production capacity | 80kg/h | 150kg/h | 300kg/h | 600kg/h |

| Gummy Weight | 2-12g | |||

| Deposuting Speed | 45-55times/min | |||

| Compressed Air Requirement | 0.4-0.6MPa 0.3m³/min |

|||

| Working Cindition | Temperature:<25℃,Humidity:<50% | |||

| Electric Power Needed | 75kW | 120kW | 120kW | 170kW |

| Total Length | 15 meters | 16 meters | 16 meters | 17 meters |

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche