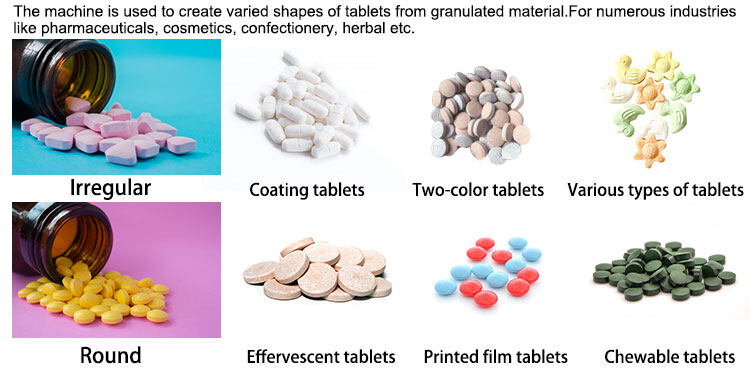

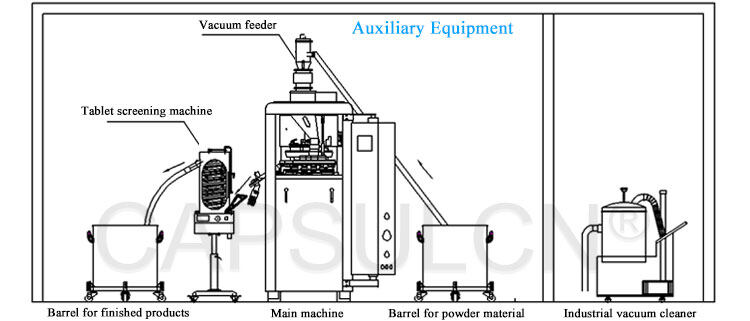

Main application:This machine is a single-press/doule-press type, continuous automatic tablet press for pressing granular raw materials into tablets. It is mainly used in pharmaceutical industry and also the chemical, food, electronic, plastic and metallurgical industries.

Introduction

GZPK high-speed rotary tablet press mainly is used in pharmaceutical industries, it can also be used in chemical, food, electronic and house wares industries. It is a facility that presses various particle materials into tablet. It can also be used to produce various tablets with exceptional figures, graphs, and tablets with letters on both sides etc.These machines are suitable for producing round and exceptional tablets in large scale like medicines, sweets, calcium etc

It is a continuous automatic tablet press which can be used in the pharmaceutical, chemical, food, and electronic industries.

Details Images

Specifications

| Model | GZPK-26 | GZPK-32 | GZPK-40 |

|---|---|---|---|

| Dies | 26 | 32 | 40 |

| Max. pressure (kN) | 100 | 80 | 80 |

| Max. dia. of tablet(mm) | 25 | 16 | 13 |

| Max. depth of filling(mm) | 20 | 16 | 16 |

| Capacity (tablets/h) | 160,000 | 210,000 | 260,000 |

| Power(W) | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz |

| Weight | 1920kg | 1920kg | 1920kg |

| Dimensions | 930x850x1945mm | 930x850x1945mm | 930x850x1945mm |

Remarks

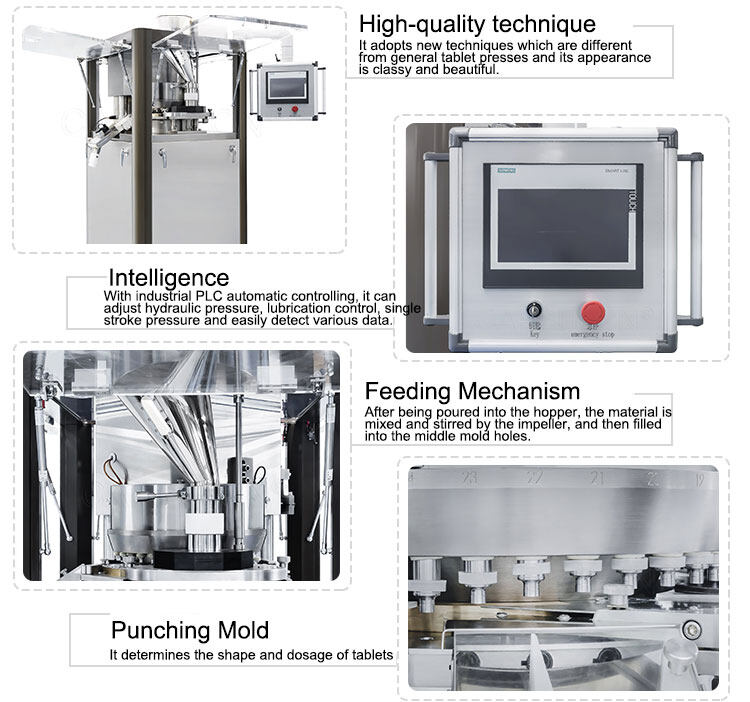

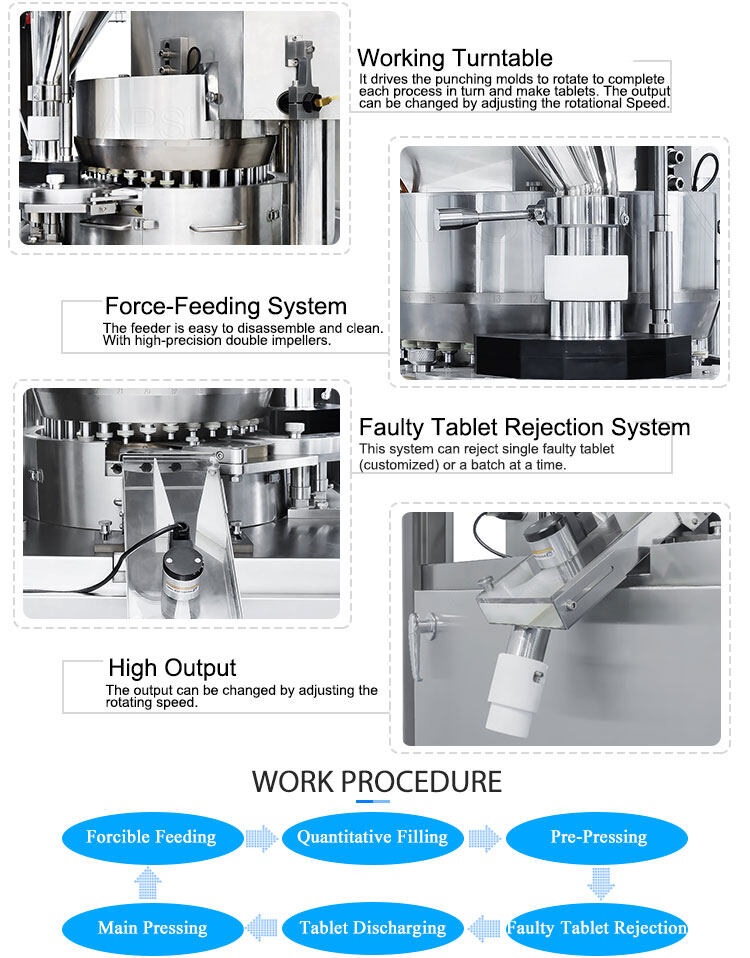

- The main components of the electric control cabinet adopt international famous brand components, PLC adopts Siemens products, and the human-machine interface adopts Siemens 10-inch series color touch screen.

- Low-voltage electrical products use ABB, Schneider, OMRON and other internationally renowned brand products

- Frequency converter adopts Siemens brand.

- The punching plate is processed with corrosion-resistant materials and has good rust and corrosion resistance.

- The mold damage of the tablet press and the supply of the powder are monitored to provide a safety protection. Greatly reduce production costs, improve the pass rate of tablets, and achieve one-person multi-machine management.

review(s)

Good Machine

Very high production efficiency, it is also perfect after more than 1 year.

From: Sean | Date: 2/27/2021 1:07 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche