Video

Introduction

NJP-1200D automatic capsule filler processes the products for optimal productivity up to 1200 capsules per minutes, featuring low-maintenance operation, minimal downtime, and overall dependable production.

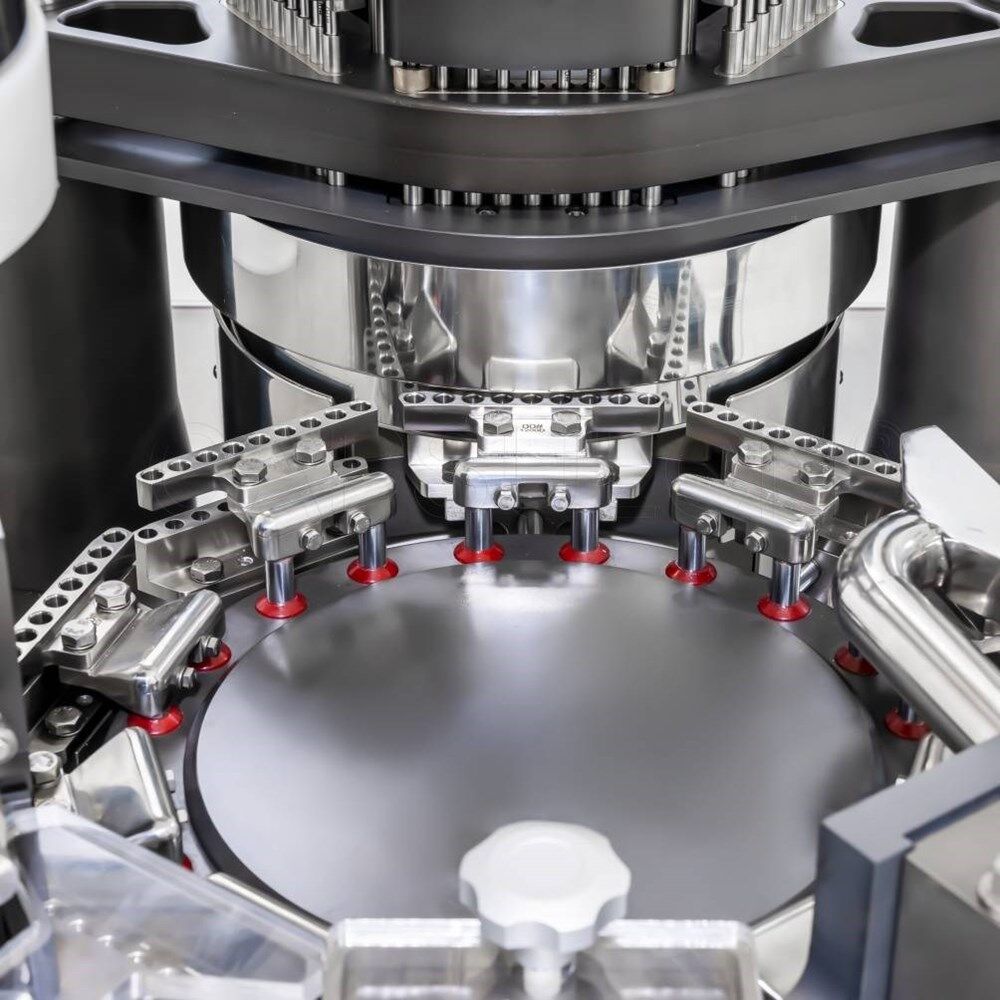

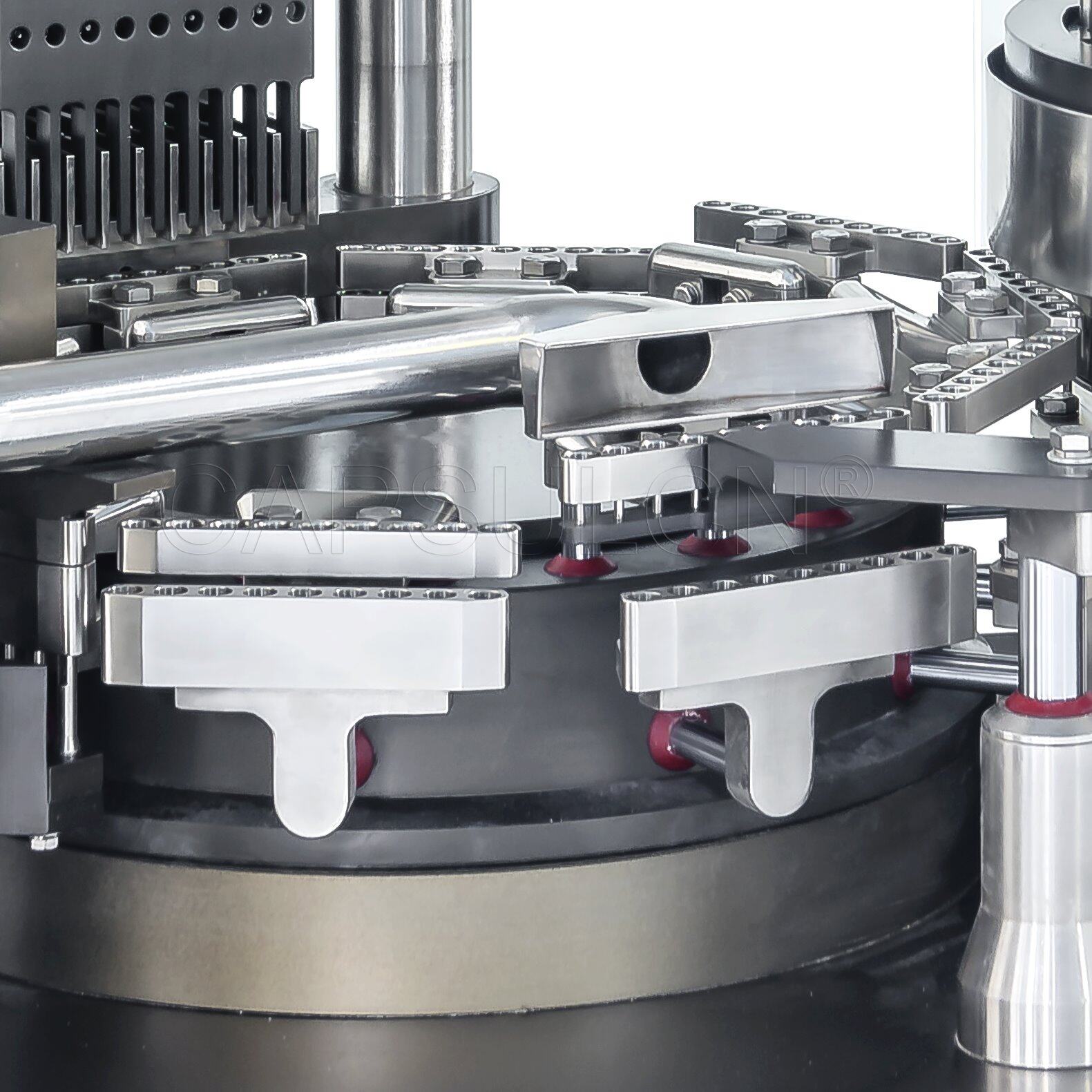

Powder dosing uses the 5 stage tamping technology for an enhanced accuracy. Filling of pellets is available.

Capsules from the bunker are fed into the orienting device along the vertical guide.

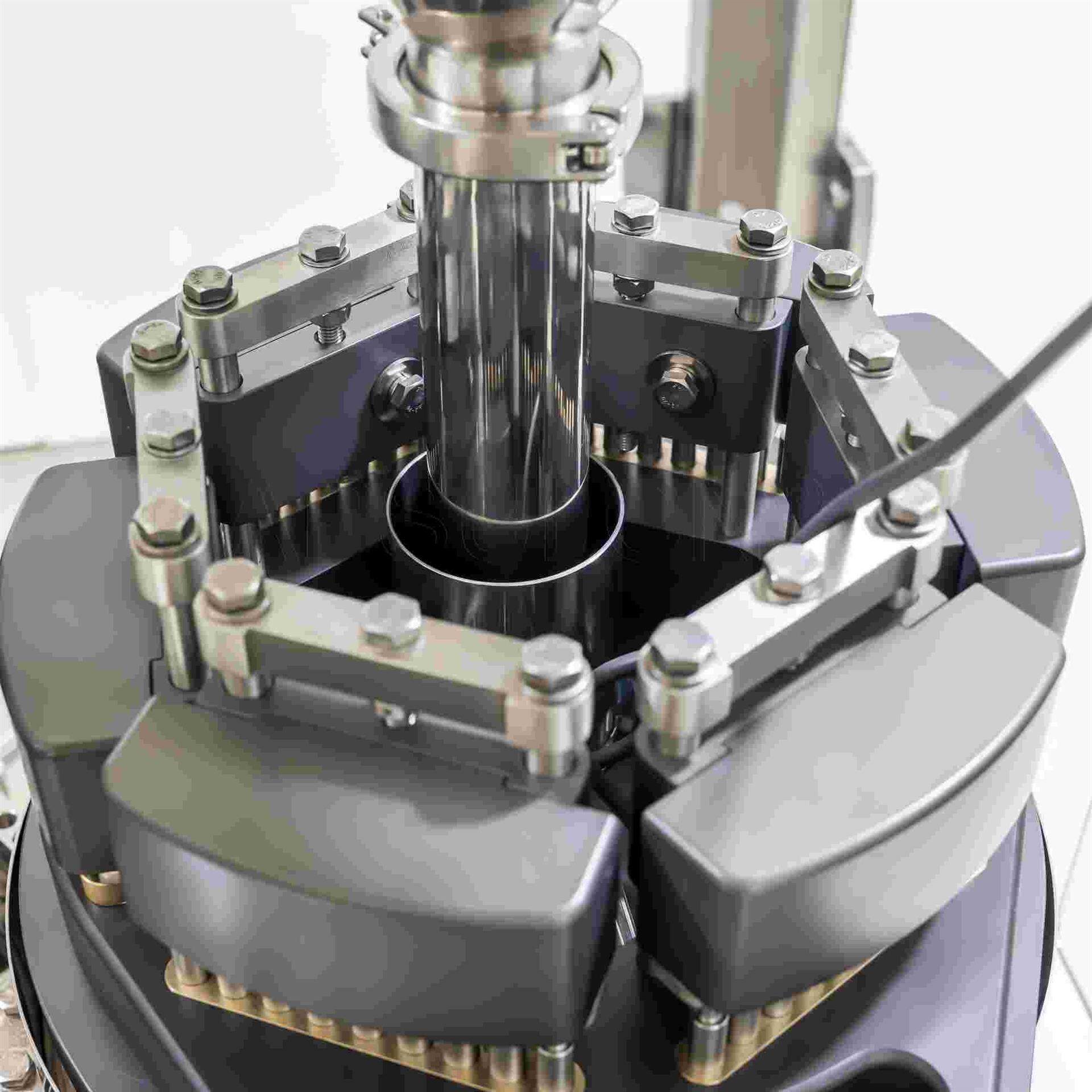

Then they are transferred into special cells on the rotor. Here the capsule is separated, after what the bottom part comes to the filling position.

After filling the bottom part with the material, on next positions the non-separated capsules are rejected, and the filled bottom parts are joined with top parts, counted and taken away into the receiving box.

The equipment design is fully in line with the requirements of CGMP and FDA specification.

Working Principle

NJP-1200D can be used to encapsulate powder, granules and pellets in pre- determined dosages.

Features

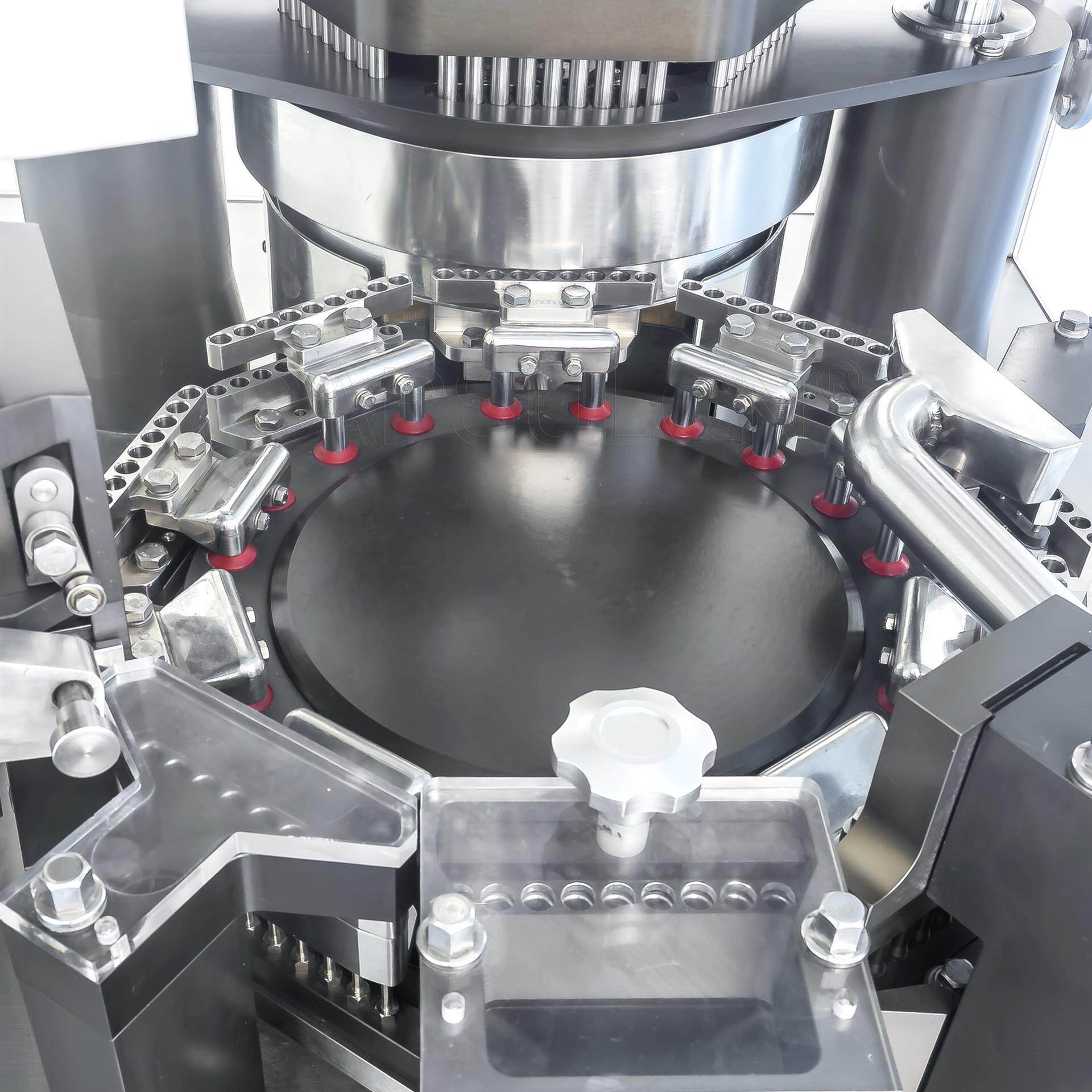

The split-type design of the capsule loading mechanism and the patented fully-enclosed structure prevent the capsules from improperly falling into the capsule transmission room and ensure the capsules to perform smoothly.

The patented powder filling mechanism includes several patented techniques like the irregular multi-surface powder keeper, the lateral angled feeder, etc., which makes the powder evenly distribute within the powder storage room, correctly and smoothly flow into the capsules, and achieves an extremely precise capsule filling process.

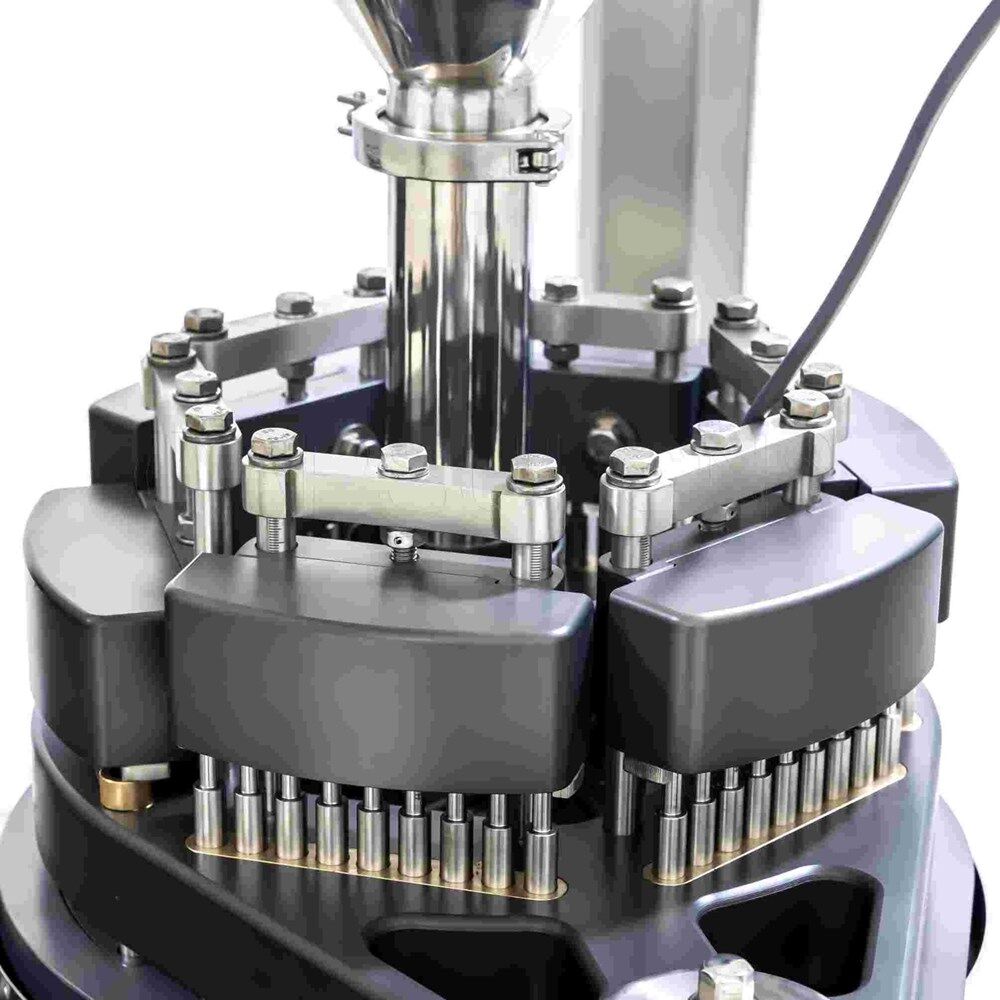

The patented integrated rotary table with ultra-precision has features like small size, light load, long service life, three years free of oil and maintenance and so on.

The capsule discharge port adopts a standard clamp design, which provides the convenience of joint for future upgrades.

The moving parts are upgraded to linear guide rails, and the radial positioning is more accurate.

The excess powder on the mold will overflow during the locking process of the capsule, and the locking structure with vacuum function effectively removes the excess powder.

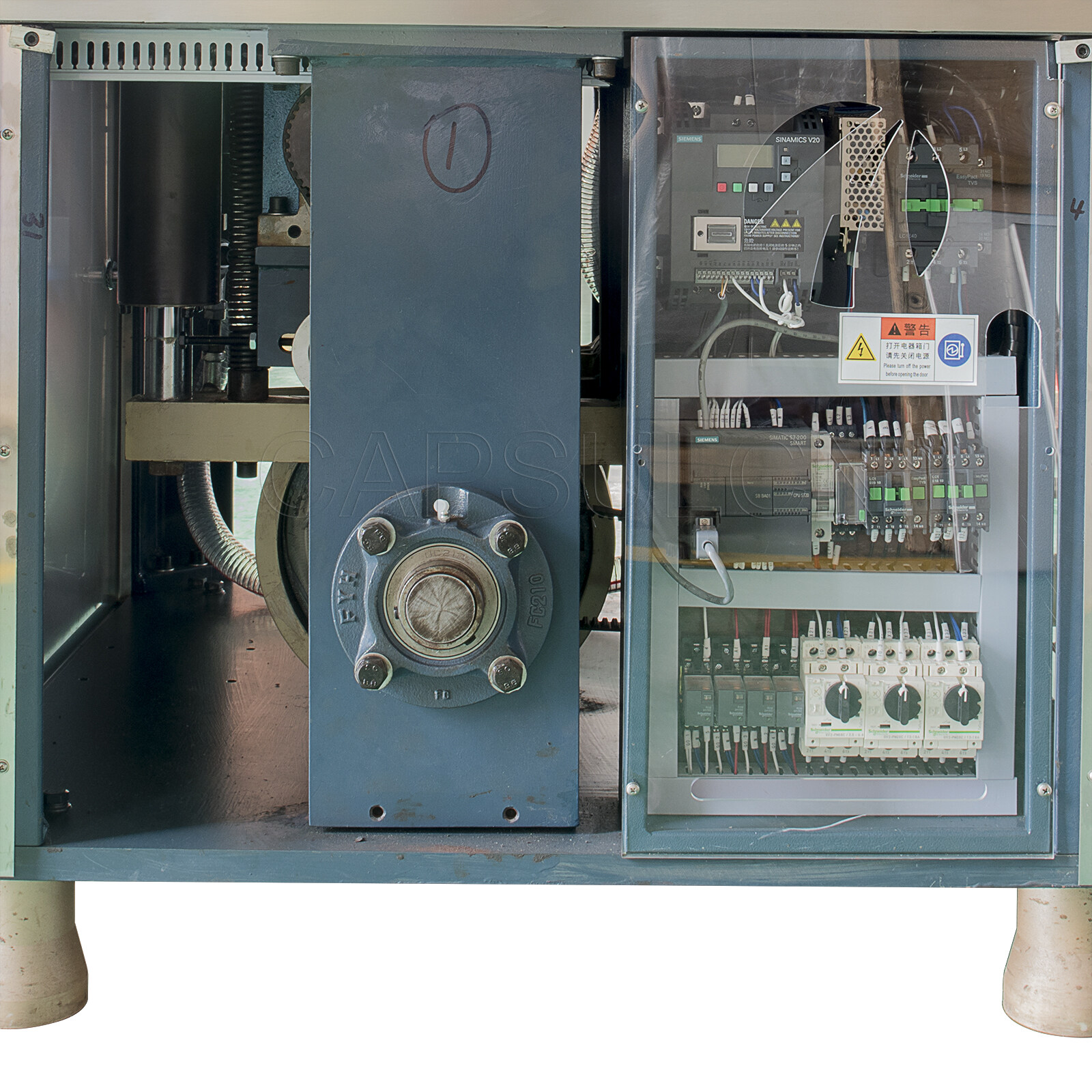

Nylon foot pads are used, which are more moisture-proof and corrosion-resistant.

The cable layout is organized and easy to maintain.

Specifications

| D Type Automatic Capsule Filling Machine | ||

|---|---|---|

| Machine model | NJP-1200D | NJP-3000D |

| Max capacity | 72000capsules /hour | 165000capsules /hour |

| Suit for capsule size | 00#-5# and safety capsule | 00#-5# and safety capsule |

| No.of mould bores | 9 | 21 |

| Power | 380 / 220V 50 / 60Hz 7kW | 380 / 220V 50 / 60Hz 11kW |

| Noise | <70dB | <70dB |

| Machine dimensions | 980x980x2100mm | 1610x1210x2180mm |

| Net weight | 1000kg | 2200kg |

| C Type Automatic Capsule Filling Machine | ||||

|---|---|---|---|---|

| Machine model | NJP-800C | NJP-1200C | NJP-2000C | NJP-3500C |

| Max capacity | 48000capsules/hour | 72000capsules/hour | 120000capsules/hour | 210000capsules/hour |

| Suit for capsule size | 00#-5# and safety capsule | 00#-5# and safety capsule | 00#-5# and safety capsule | 00#-5# and safety capsule |

| No.of mould bores | 6 | 9 | 18 | 26 |

| Power | 380V,50Hz,5.05kW | 380/220v,50/60Hz,6kW | 380/220v,50/60Hz,10kW | 380/220v,50/60Hz,12kW |

| Noise | <75dB | <75dB | <75dB | <75dB |

| Machine dimensions | 1080x1240x1930mm | 1180x1340x1980mm | 1500x1350x2100mm | 1386x1156x2100mm |

| Net weight | 800 kg | 1000kg | 1600kg | 2500kg |

Remarks

- Powder filling system is very high filling accuracy.

- The capsule-type rejection system effectively protects the filled capsules from breaking by the machine.

- The patented modular punch as well as the bi-nodal feed hopper is of simple dismounting and with accurate positioning.

- All the connectors of the air pipes apply standardized clamps, which are much easier to dismantle and clean than others.

- The whole set of the molds and all the parts that need daily cleaning and maintenance are equipped with locating pins, and the connection as well as fastening among different parts is extremely simple. As the fastening tool is standardized in size, a small spanner can easily dismount all the parts.

review(s)

Very stable machine

I really like the 1 year maintenance-free function, and the engineers are also very convenient to maintain.

From: Sean | Date: 2/27/2021 1:09 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Automatic Capsule Filler & Encapsulation Machine NJP-1200C

Automatic Capsule Filling Machine NJP-3500C

Automatic Capsule Filling Machine NJP-800C

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche