Video

Introduction

With the development of the pharmacy machine’s technology, how to improve the automatization process of pharmacy machine and the efficiency of the produce become more and more urgent. In order to meet the requirements of the pharmacy machine’s development, we design and produce a fully enclosed automatic capsule-filling machine on the basis of the former NJP-series machine. This machine’s structure, power supply controlling, vacuum and aspirate system are all ameliorated innovatively. We can say it is really the most advanced machine in the pharmacy machinery producing line. Generally speaking, it is the machine which concentrating the structure, electric and air to a body.

The machine equipped with the various segments for suitable capsules, namely 00#,0#, 1#, 2#, 3# and 4#.

The equipment design is fully in line with the requirements of CGMP and FDA specification.

Specifications

| C Type Automatic Capsule Filling Machine | ||||

|---|---|---|---|---|

| Machine model | NJP-800C | NJP-1200C | NJP-2000C | NJP-3500C |

| Max capacity | 48000capsules/h | 72000capsules/h | 120000capsules/h | 210000capsules/h |

| Suit for capsule size | 00#-5# and safety capsule | 00#-5# and safety capsule | 00#-5# and safety capsule | 00#-5# and safety capsule |

| No.of mould bores | 6 | 9 | 18 | 26 |

| Power | 380V,50Hz,5.05kW | 380/220v,50/60Hz,6kW | 380/220v,50/60Hz,10kW | 380/220v,50/60Hz,12kW |

| Noise | <75dB | <75dB | <75dB | <75dB |

| Machine dimensions | 1080x1240x1930mm | 1180x1340x1980mm | 1500x1350x2100mm | 1386x1156x2100mm |

| Net weight | 800 kg | 1000kg | 1600kg | 2500kg |

| D Type Automatic Capsule Filling Machine | ||

|---|---|---|

| Model | NJP-1200D | NJP-3000D |

| Capacity | 72000capsules/h | 165000capsules/h |

| No.of mould bores | 9 | 21 |

| Capsule size | 000#-5# and safety capsule | 000#-5# and safety capsule |

| Power | 380/220V,50/60Hz,7kW | 380/220V,50/60Hz,11kW |

| SNR | <70dB | <70dB |

| Dimensions | 980*980*2100mm | 1610*1210*2180mm |

| Net weight | 1000kg | 2200kg |

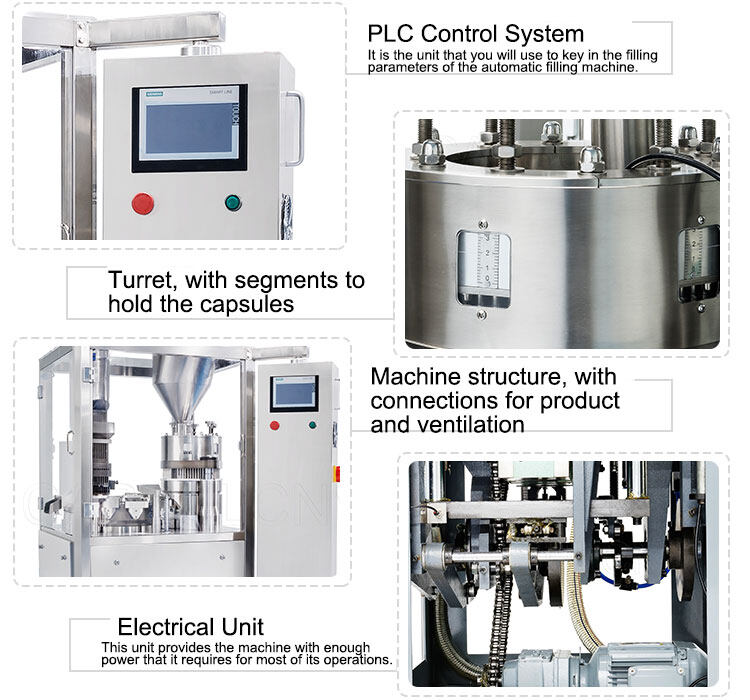

The main innovated parts

- With the patent technology of totally enclosed patent technology in the working table, it solves the inconvenience of dismantling and washing moulds, and the problem of adjusting mould assembly precision.(Patent No.: ZL 99 2 54535.8)

- The dose adjusting device adopts stand adjusting patent technology, which can conduct trim the dose under no-stop state.(Patent No.: ZL 99 2 54534.X)

- Adopting the lower cam structure in the working table rotation , it has good lubrication results and low wearing , prolonging the service life of the parts .

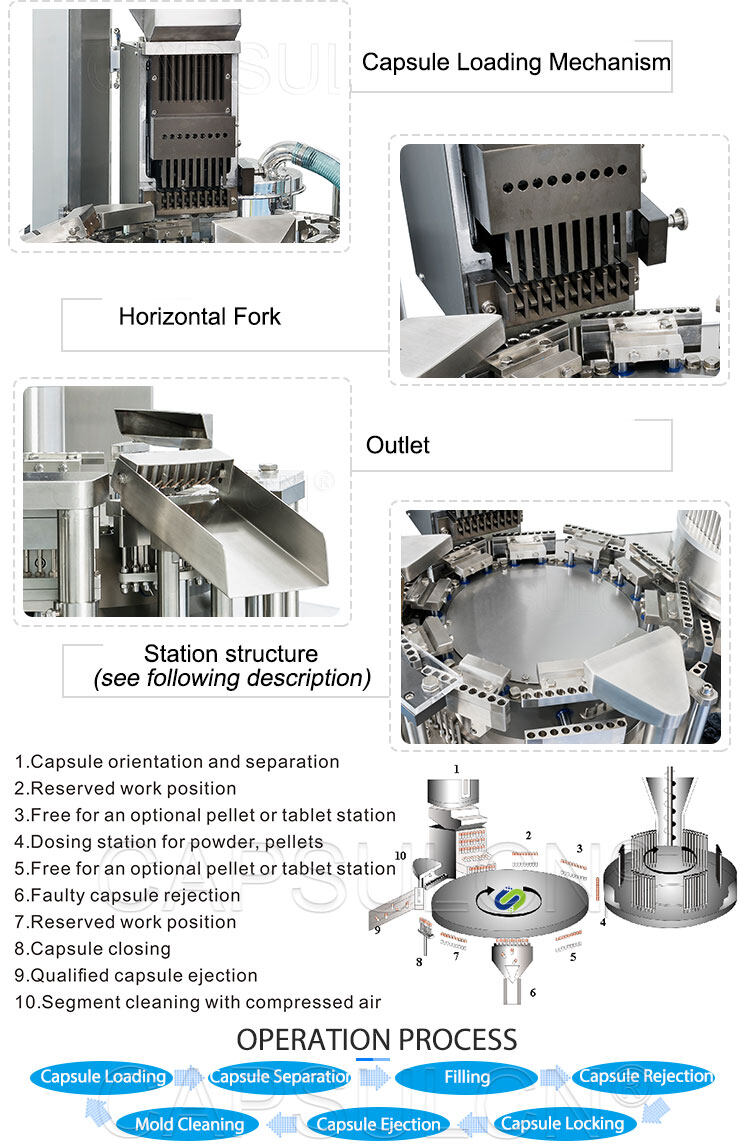

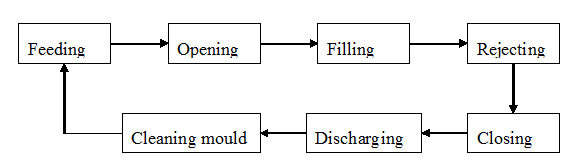

Working principle and main structure

This machine is a precise intermittent moving capsule filling machine, the following is its working flow chart.

Remarks

- cGMP design with emphasis in powder dust handling: Enclosed main turn table avoid dust getting into mechanical parts.

- Automatic control for capsule and powder supply.

- PLC control for reliable operation. Touch Screen HMI, featuring user friendly controls: production counter, manual / automatic / parameter setup modes, alarms.

- Precision capsule segments and dosing disk minimizes adjustments following parts changeover.

- SS 304 stainless steel frames and transparent safety interlock guards.

review(s)

Operation

Installation

From: Guest | Date: 1/5/2020 8:14 PM

Capsule Machine

innovative!

From: Guest | Date: 3/6/2020 8:23 PM

Fouzi

Belhadji

From: Guest | Date: 3/13/2020 11:23 AM

Good

Good

From: Guest | Date: 3/15/2020 11:11 AM

Capsule Machine

innovative

From: Guest | Date: 3/22/2020 10:33 PM

:3

Niccceeeeee

From: Guest | Date: 4/7/2020 7:00 AM

IPHARMACHINE

So good

From: Guest | Date: 4/8/2020 4:15 AM

Review

Nice machine

From: Guest | Date: 4/12/2020 10:53 AM

Great

Good one

From: Guest | Date: 4/15/2020 3:41 AM

Great

Wonderful

From: Guest | Date: 4/15/2020 9:55 AM

Perfect

Machine good

From: Guest | Date: 4/15/2020 1:39 PM

3

Beautiful

From: Guest | Date: 4/15/2020 7:59 PM

Awesome

Machine good

From: Guest | Date: 4/15/2020 8:07 PM

Great

Fine

From: Guest | Date: 4/15/2020 8:10 PM

Jhairo Daniel León Carreon

Mejor ap pp

From: Guest | Date: 4/16/2020 8:45 AM

Awesome

Machine good

From: Guest | Date: 4/18/2020 4:17 PM

Not helpful

Don't understand

From: Guest | Date: 4/18/2020 6:18 PM

Innovative

Very good

From: Guest | Date: 4/20/2020 6:24 PM

Ambrose

Kenny

From: Guest | Date: 4/21/2020 7:21 AM

ok

nice

From: Guest | Date: 4/22/2020 9:47 PM

Reseña

Reseñas

From: Guest | Date: 4/23/2020 10:50 PM

Capsulas

Máquina para hacer capsulas

From: Guest | Date: 4/23/2020 11:06 PM

GOOD

Very nice

From: Guest | Date: 4/30/2020 5:08 PM

Buena máquina

Es una máquina extraordinaria que bien

From: Guest | Date: 5/1/2020 1:37 PM

Muy operativo

Es funcional

From: Guest | Date: 5/1/2020 3:45 PM

Alisson

Soto

From: Guest | Date: 5/2/2020 2:16 PM

María

Quiros

From: Guest | Date: 5/2/2020 3:15 PM

Awesome

Very good

From: Guest | Date: 5/3/2020 5:21 PM

Alan steven

Rodriguez antelo

From: Guest | Date: 5/4/2020 7:43 PM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Automatic Capsule Filling Machine NJP-3500C

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche