Introduction

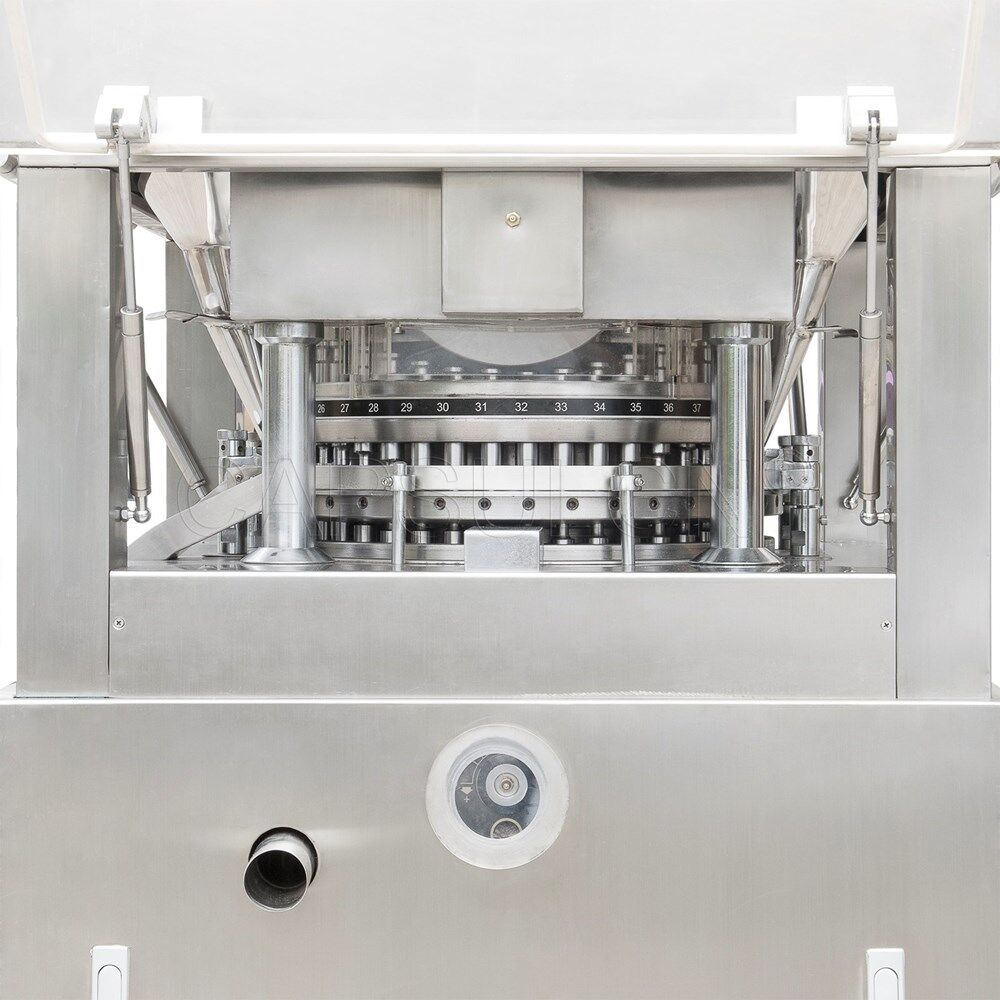

1. This is a machine with automatic rotation, frequency conversion and speed regulation, and continuous tablet pressing. It is mainly used in the manufacture of tablets in the pharmaceutical industry, and it is also used in chemical, food, electronics and other industrial sectors to compress granular raw materials into tablets.

2. The machine is used for pressing granular raw materials with a powder content (above 100 mesh) not exceeding 10%. The machine is not suitable for powder pressing of semi-solid, wet granules, low melting point, moisture-prone raw materials and no granules.

3. This machine can press 4~13mm round, special-shaped and engraved tablets, and press 18mm tablets according to the order requirements. ZPH31 model can also be used to press 4~18mm round, special-shaped, double-sided lettering, ring, double-layer and double-color tablets.

Specifications

| Model | ZP-41D |

|---|---|

| Punch quantity (set) | 41 |

| Max. tablet pressure (kN) | 80 |

| Max. tablet diameter (mm) | 13(18) |

| Max. tablet thickness (mm) | 6 |

| Max. filling depth (mm) | 15 |

| Max. production capacity (pc/h) | 170,000 |

|

Turntable working diameter(mm) |

420 |

|

Turntable speed(rpm) |

14~36 |

|

Die diameter (mm) |

26 |

|

Die height(mm) |

22 |

|

Upper and lower punch length(mm) |

115 |

|

Machine footprint (mm) |

1230*950 |

| Machine height (mm) | 1,670 |

| Machine weight (kg) |

1,700 |

Remarks

-

Check the parts regularly, 1~2 times a month. Check whether the movable parts such as worm wheel, worm, bearing, pressure wheel, upper and lower guide rails can rotate flexibly, and repair defects such as serious wear and tear in time before using. In particular, the life of the pressure roller and the top of the punch is limited to one million contacts, otherwise fatigue damage will occur.

-

After one use, the remaining powder should be taken out, and the remaining powder in each part of the machine should be brushed. If it is not used for a long time, all the dies must be removed, the surface of the machine parts should be painted with anti-rust oil, and covered with a cloth tarpaulin.

-

The punching die should be placed in a covered oil-soaked metal box and kept clean to prevent rust and bruising.

-

Pay attention to the working environment conditions when using electrical components (referring to temperature and humidity), especially the frequency converter should be handled with care, and generally should be sent to professional manufacturers for maintenance.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche