Video

Introduction

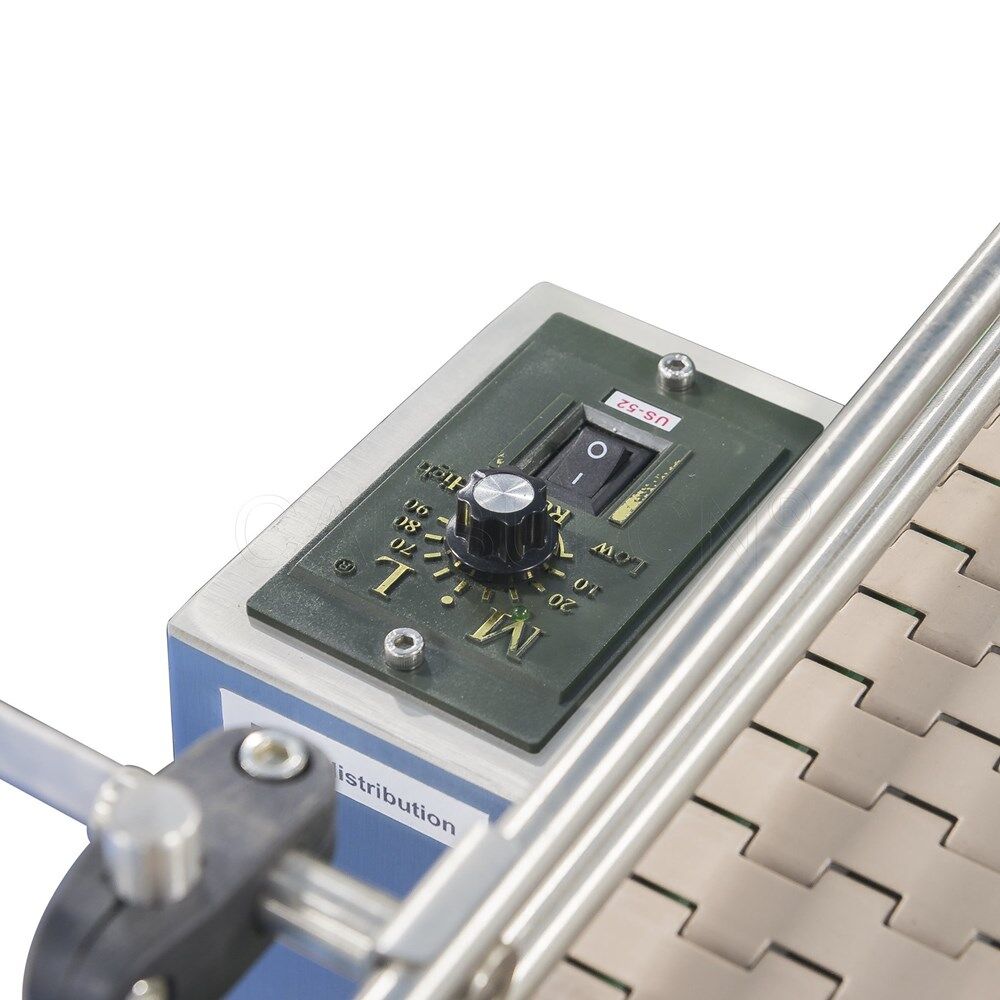

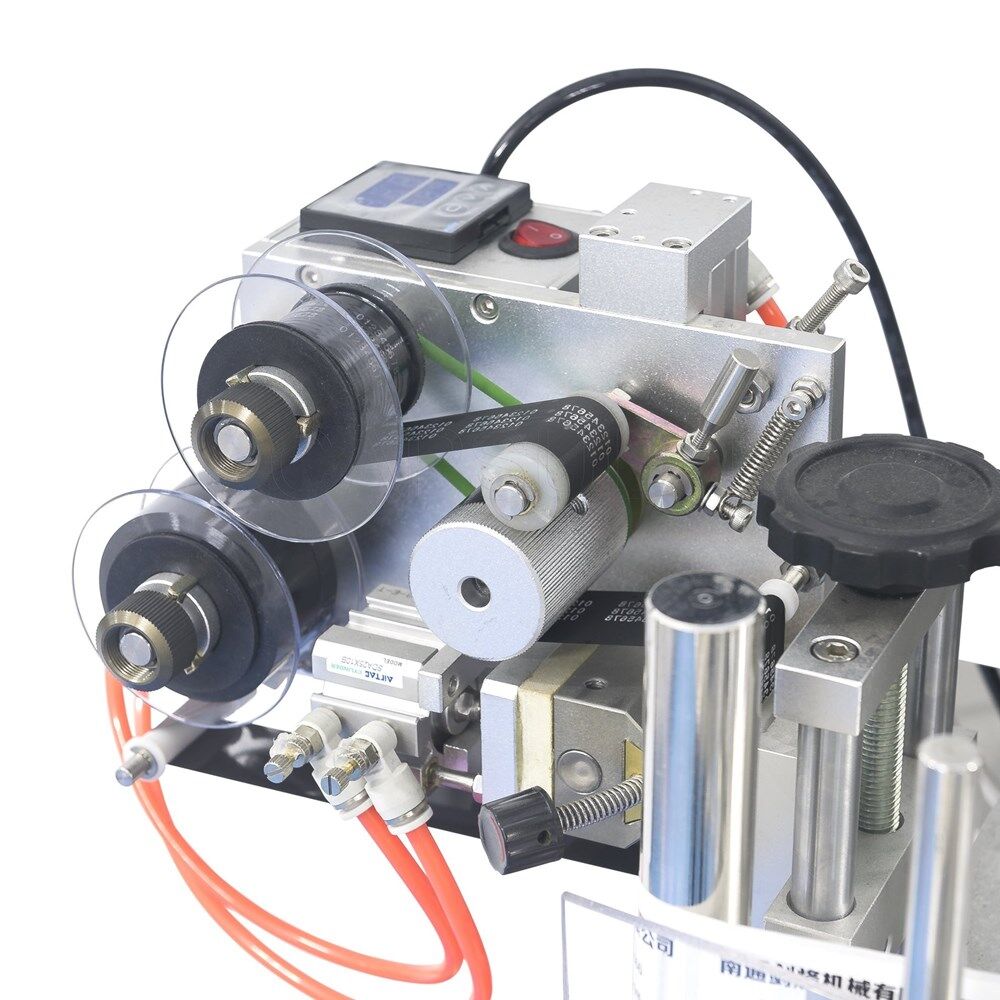

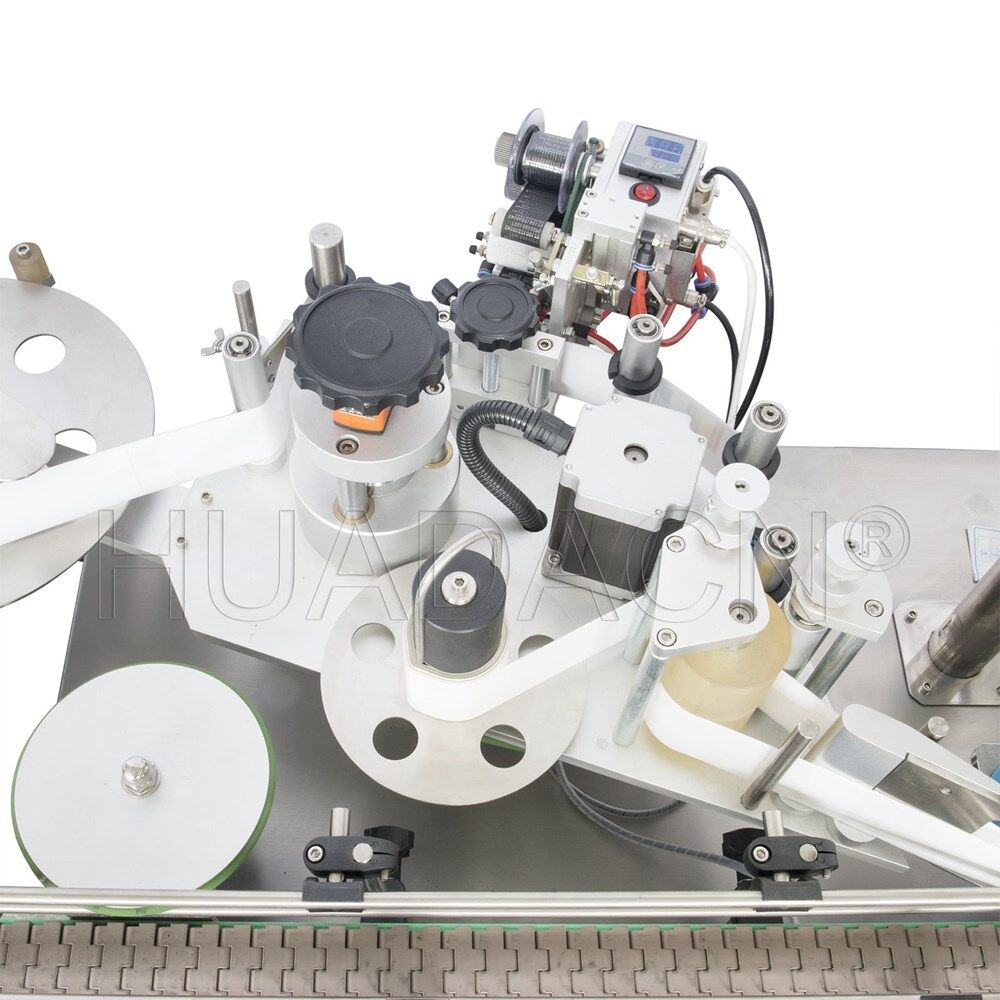

The bottles that need to be labeled are transported by the bottle conveying track, and the bottles are pulled apart equidistantly by the bottle distance adjustment mechanism. The photoelectric sensor senses the passing bottle and sends out a signal. The drive system receives the signal and starts to send the label. The tensioning system realizes the tensioning of the standard paper tape, and the tape is coded by the coding machine. The label positioning photoelectric sensor position the label according to the length, so that the length of each label pulled out is equal. Under the action of the labeling part and the pressing part, the label is automatically peeled off and pasted on the required position of the bottle to complete the whole labeling process.

Feature

- Strong compatibility-suitable for all kinds of round objects.

- It adopts a tension design for label moving-it can not only ensure the quality of the coding, but also accurately control the length of the label and the uniformity of the starting label.

- Adopt the pre-release labeling system-the discharging is stable, the labeling is smooth, and the position accuracy is high.

- Quality assurance of labeling-rolling label paper adopts different methods for different bottle types.

Specifications

| Model | CED-TB201 |

|---|---|

| Applicable bottle type | 15~500ml round square bottle |

| Production capacity | 30~120 bottles/min |

| Power supply | AC220V 50Hz |

| Power | 150W |

| Gas source | 0.6MPa |

| Dimensions | 1650*800*900mm |

| Machine weight | 150kg |

Remarks

-

The installation and use environment: it is required to be at room temperature, and it is not suitable to be used in a high temperature, humid, acidic and alkaline environment for a long time, so as not to affect the service life, efficiency and accuracy of the machine.

-

Tools and materials used: dry soft cloth, compressed air, anti-rust oil.

-

It is necessary to check whether there are debris on the stripping plate, ribbon, label rolling mechanism, etc.

-

The reliability of compressed air pipelines and joints should be dealt with in time if there is any looseness or leakage.

-

Check whether the power supply is normal and whether the power cord is damaged.

-

The machine should be well grounded.

-

Test to run the machine to see if there is any abnormality. If there is, it should be solved in time.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Automatic Continuous Mill Herb Grinder WF Series

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche