Also bought

Video

Introduction

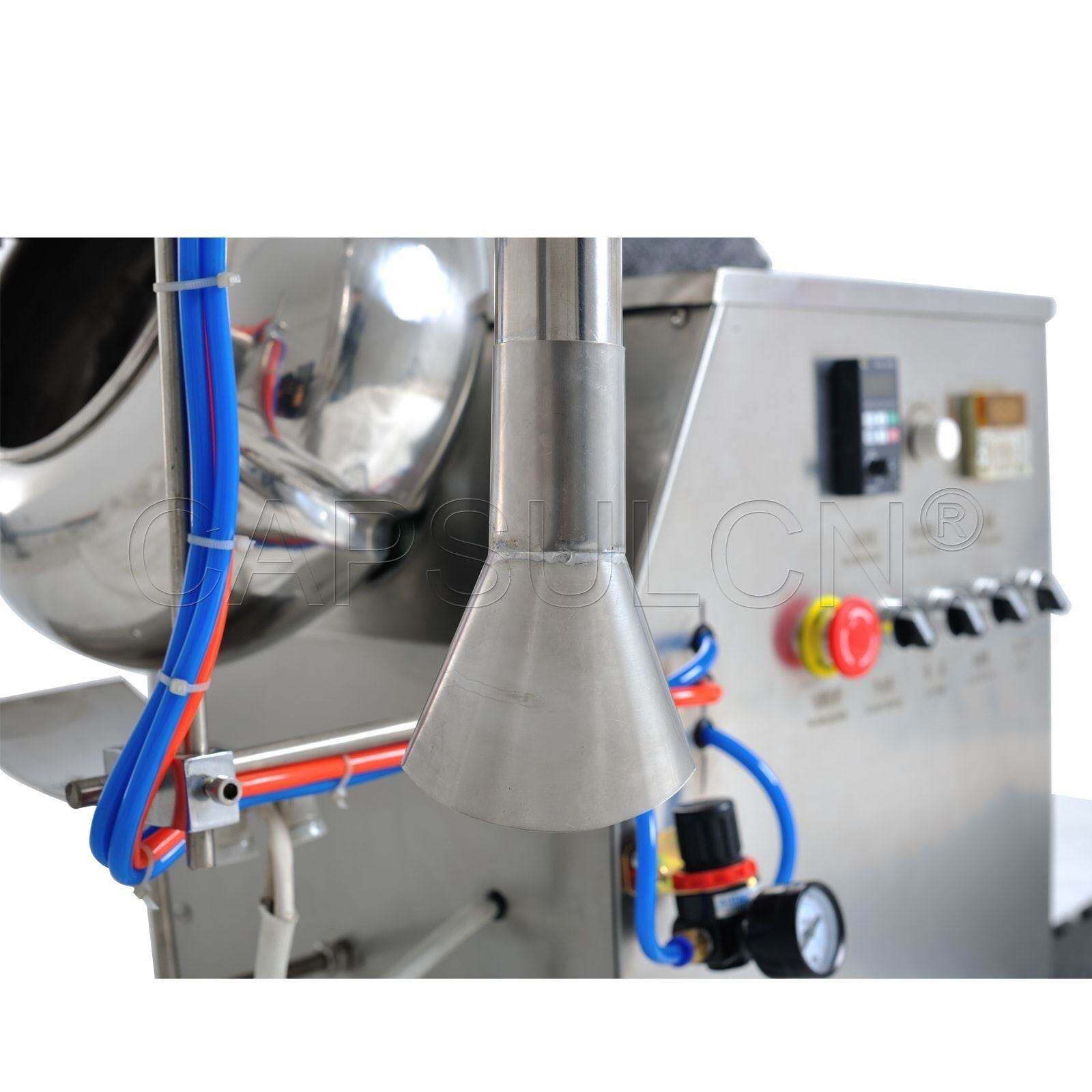

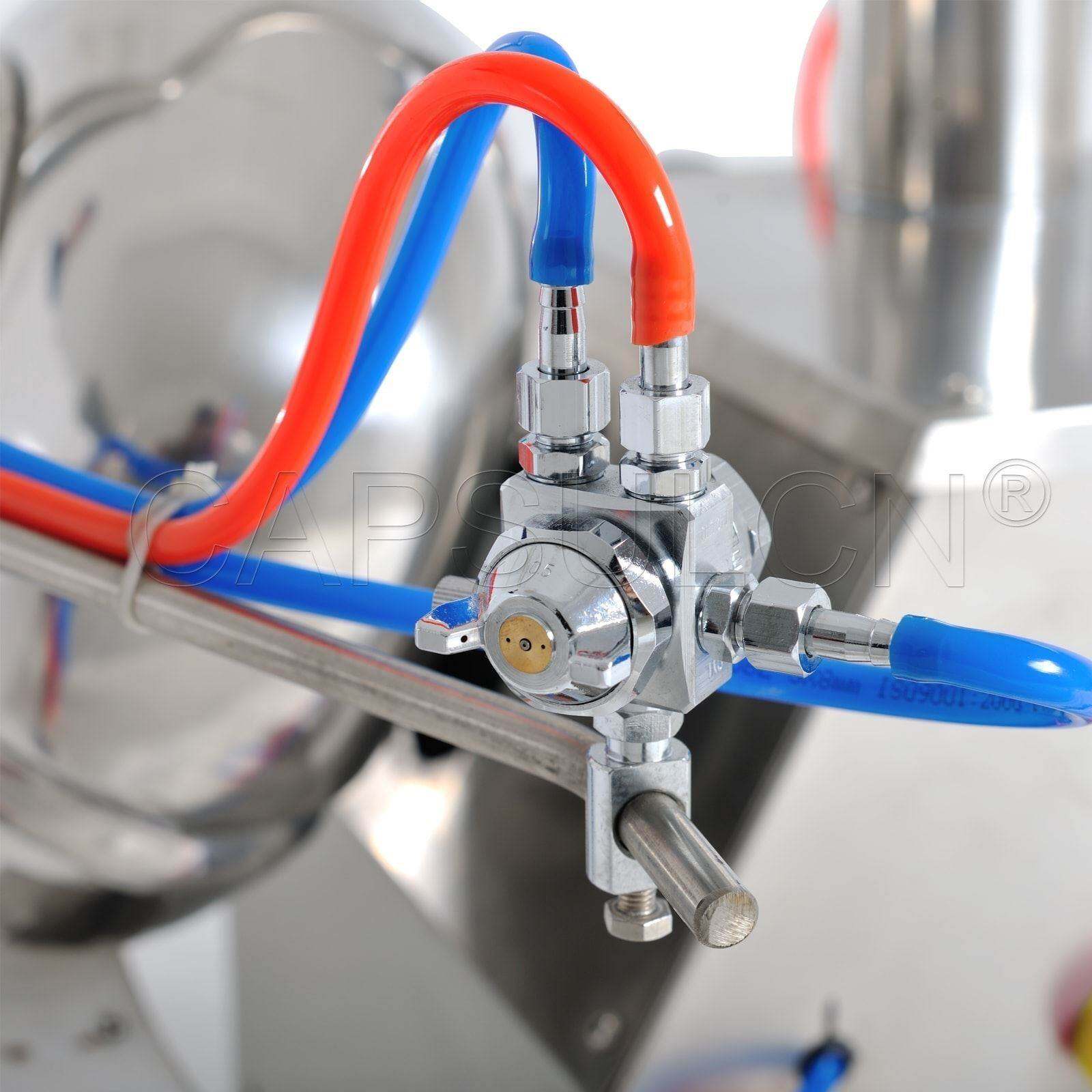

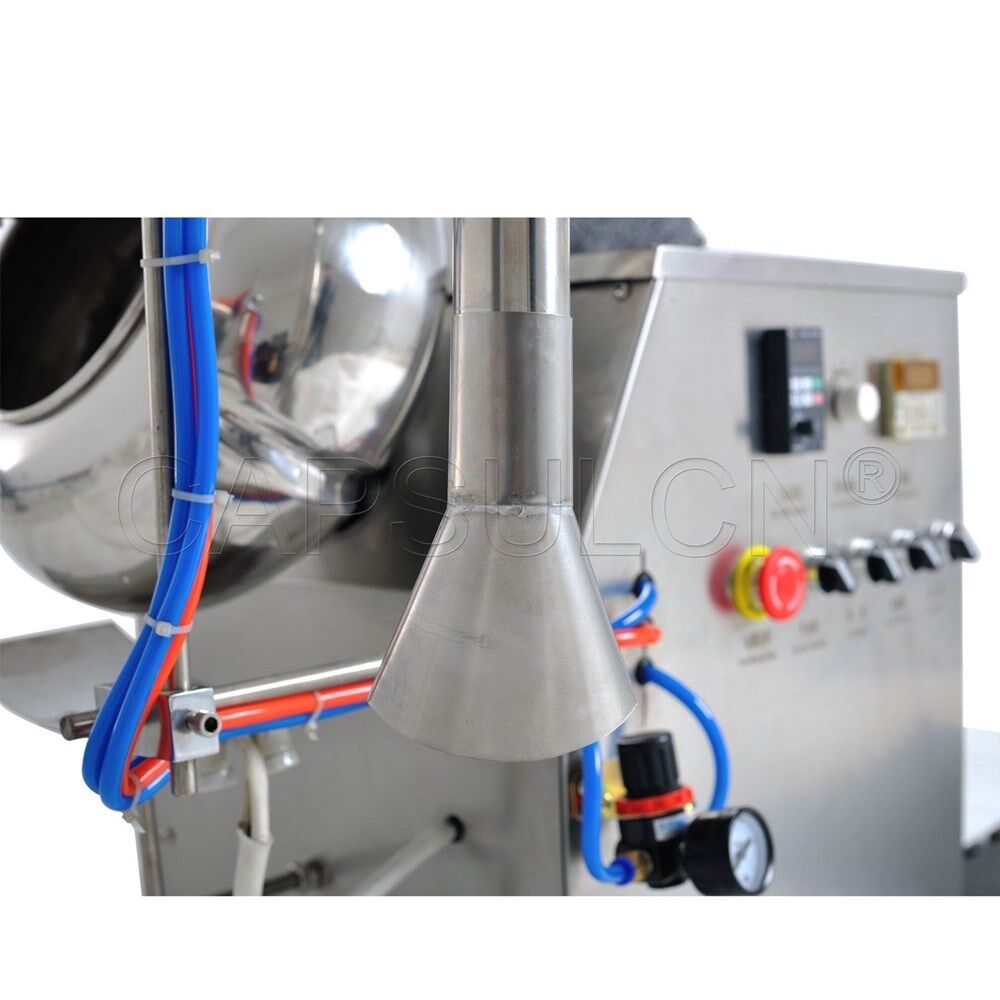

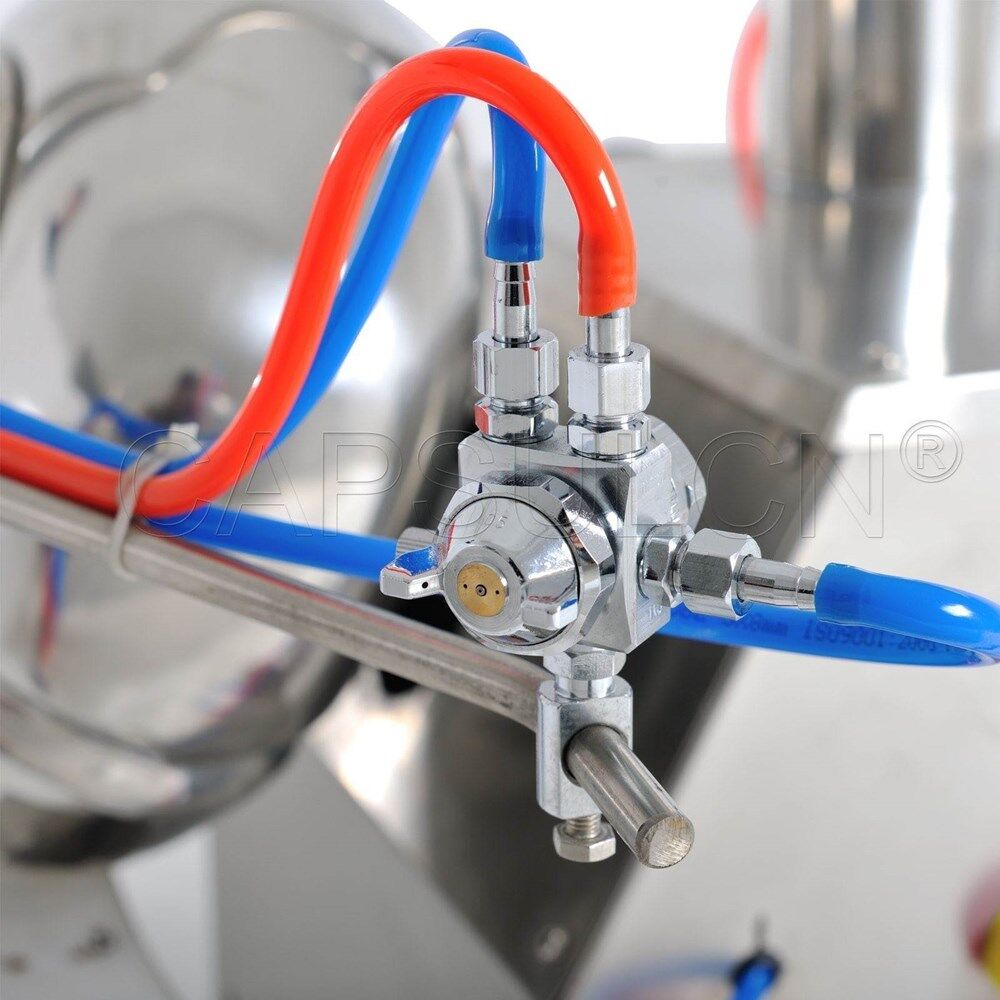

This machine is a kind of equipment which can coat the outer surface of Chinese and Western medicine tablet cores with a layer of sugar or film. It integrates strong current, weak current, hydraulic pressure and pneumatics, and comes into being by reforming the original common sugar-coating machine. It is mainly composed of the main machine (original sugar-coating machine), controllable room-temperature hot air system, automatic liquid and air feeding spray system, etc. The main motor can achieve speed adjustment through frequency conversion. When the high atomization sprayer works, the high-pressure air flow forms a negative pressure in the inner cavity of the sprayer, and the coating liquid is atomized and sprayed on the surface of tablets under the action of atmospheric pressure. At the same time, the tablets move continuously in the coating pot to make the coating liquid evenly cover the cores of the tablets. Meanwhile, there is controllable room-temperature hot air in the coating pot to dry the tablets, so as to quickly cover tablets with a layer of solid, fine, complete and smooth film.

Specifications

| Model | BYC-300 | BYC-400 | BYC-600 | BYC-800 | BYC-1000 | BYC-1250 |

|---|---|---|---|---|---|---|

| Capacity | 1-3kg/cycle | 2-5kg/cycle | 8-15kg/cycle | 30-50kg/cycle | 50-70kg/cycle | 80-150kg/cycle |

| Pot inclination | 42° | 42° | 30° | 30° | 30° | 30° |

| Motor power | 0.37kW | 0.37kW | 0.75kW | 1.1kW | 1.5kW | 2.2kW |

| Blower power | 60W | 60W | 100W | 200W | 200W | 370W |

| Pot volume | 1L | 1L | 5L | 8L | 10L | 20L |

| Heating power | 1.4kW | 1.4kW | 2kW | 3kW | 4kW | 6kW |

| Rotational speed | 0-46r/min | 0-46r/min | 0-40r/min | 0-32r/min | 0-32r/min | 0-28r/min |

| Weight | 49kg | 50kg | 150kg | 280kg | 300kg | 500kg |

Remark

- This machine is of reliable operation and stable performance. The control system composed of PLC and HMI has reasonable design and flexible programming, meeting the needs of various pharmaceutical processes.

- As the inclination of the coating pot is adjustable, all kinds of coating powder are available.

- It has a wide range of application, suitable for coating tablets and pills in the pharmacy industry, chemical industry, foods, research institutes and hospitals.

review(s)

Happy shopping

This new type of coating machine brings a fundamental change in tablet coating technology. The tablet is placed in a cascade of tablet motions, which brings a higher liquid coating rate than traditional coating pans.

From: Davis | Date: 3/1/2021 4:06 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche