Also bought

Introduction

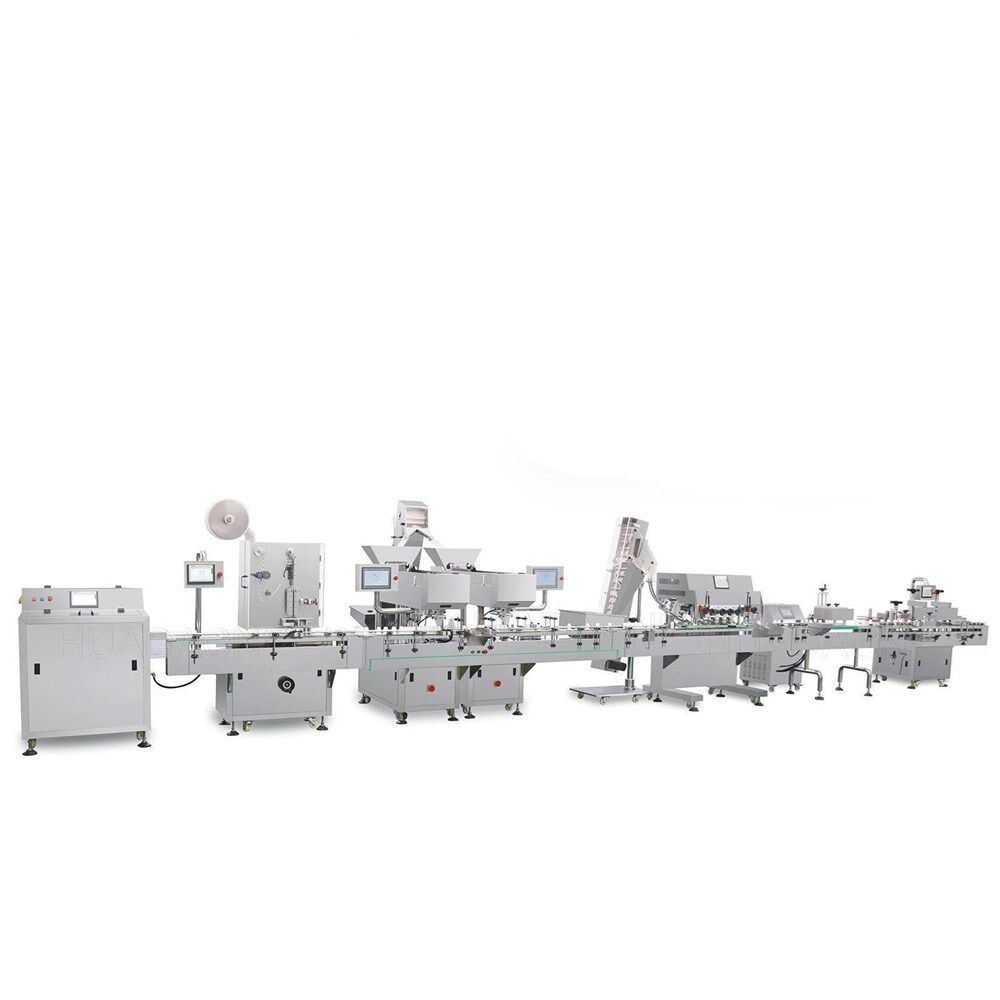

This machine is a intelligent automatic counting and filling machine, which is widely applied for capsule counting for big scale production in hospital, pharmaceutical factory etc.

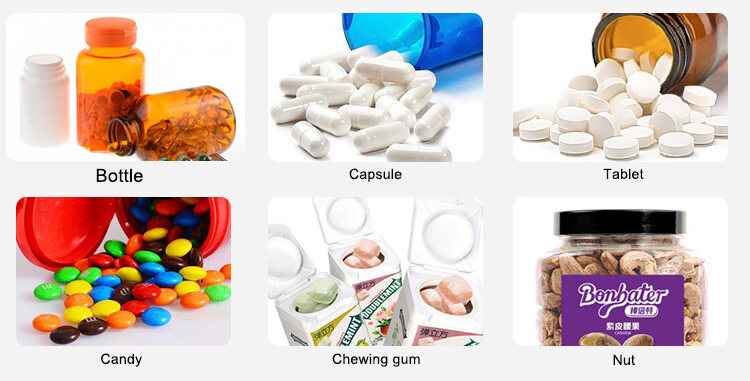

The machine can count & fill different shapes or size of products accurately like soft gel capsules, hard capsules, tablets, sugar coating, and film coating tablets, pills, herb medicine or similar products into containers or vials.

High speed PLC system controls the whole process including counting, filling and monitoring. The machine counts precisely, quickly. Put bottle by conveyer belt and fill automatically, high differentiate rate, fast responding speed.

Some accessory equipments can be connected like feeding turntable, capping machine and Labeling machine and so on.

Specifications

| Model | PBDS-8 | PBDS-12 | PBDS-16 | PBDS-24 |

|---|---|---|---|---|

| Production capacity | 10~50 bottles per minute | 20~55 bottles per minute | 60-100 bottles per minute | 80-150 bottles per minute |

| Container size | Dia.:20~100mm Height:50-100mm |

Dia.:20~100mm Height:40~200mm |

Dia.:20~100mm Height:40~220mm |

Dia.:20~100mm Height:40~220mm |

| Size of capsule/tablet | Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

| Main power | 0.4kW | 1.5kW | 1.5kW | 1.7kW |

| Power supply | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz |

| Weight | 450kg | 480kg | 780kg | 850kg |

| Overall dimensions | 1600x1500x1600mm | 1600x1500x1600mm | 2600x1600x1600mm | 4200x1800x1600mm |

Detial Images

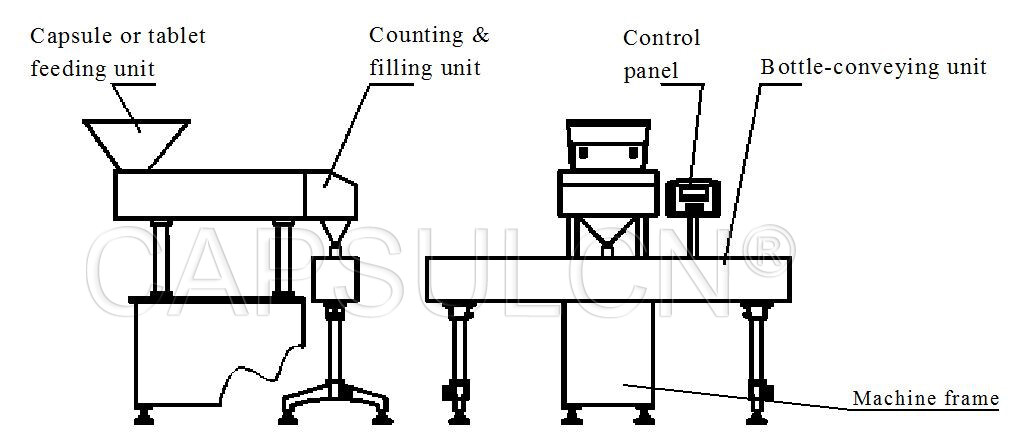

This equipment consists of counting and filling mechanism, unloading mechanism (hopper), bottle conveying mechanism, chassis and electrical control system.

Acrylic cover sheets can effectively prevent items from falling and scattering during transportation, avoiding safety hazards and material waste.

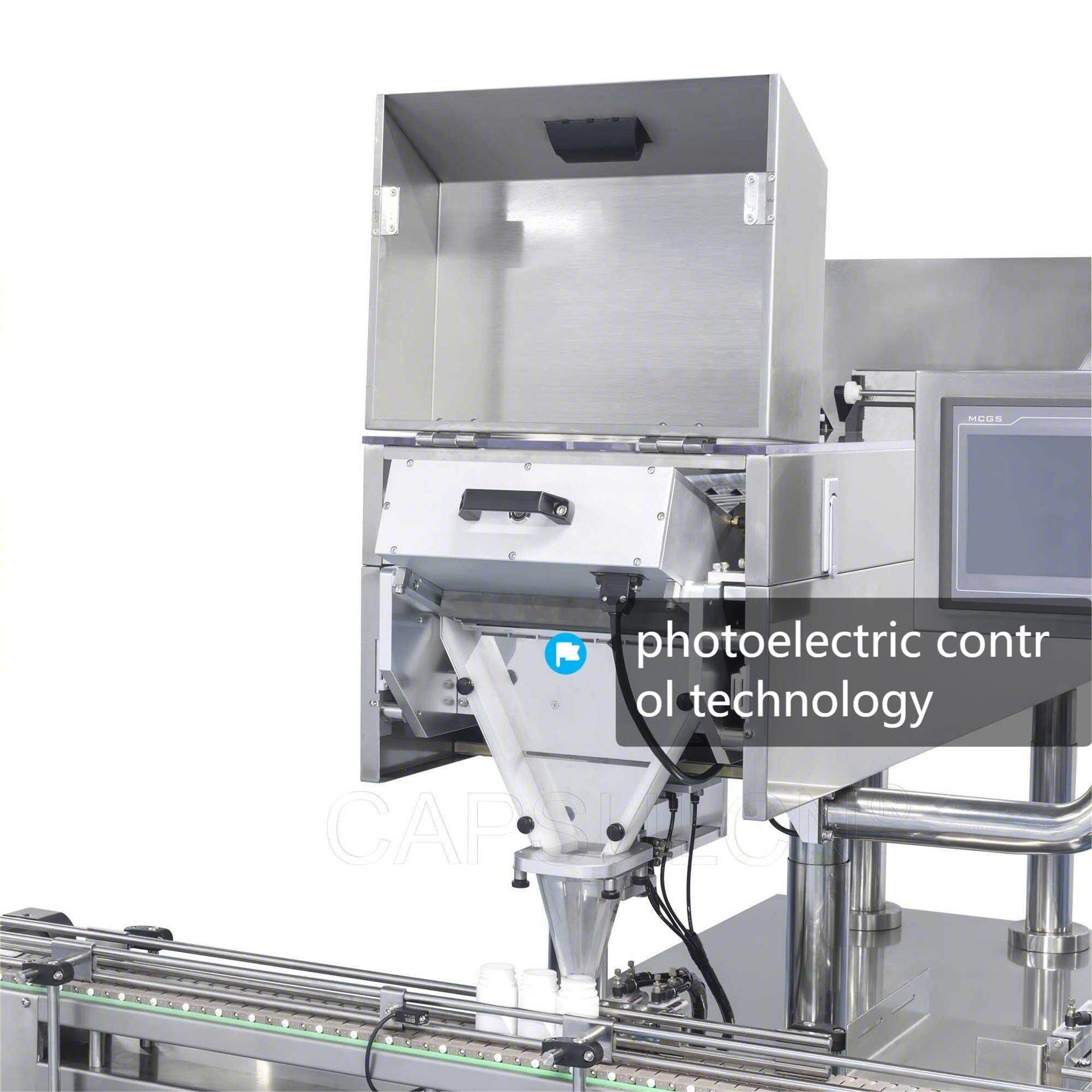

The application of photoelectric control technology makes the operation of the grain counting machine more flexible and reliable, and can improve the production efficiency and accuracy of the grain counting machine.

Multiple channels can increase the speed, shorten the material distribution time, improve efficiency, make the drug particles uniform, and avoid missing or overloading.

Computer control technology simplifies operation and improves the efficiency and accuracy of the counting machine.

The double outlet design improves production efficiency, production flexibility, and simplifies the production process. It is an economical, efficient and reliable solution.

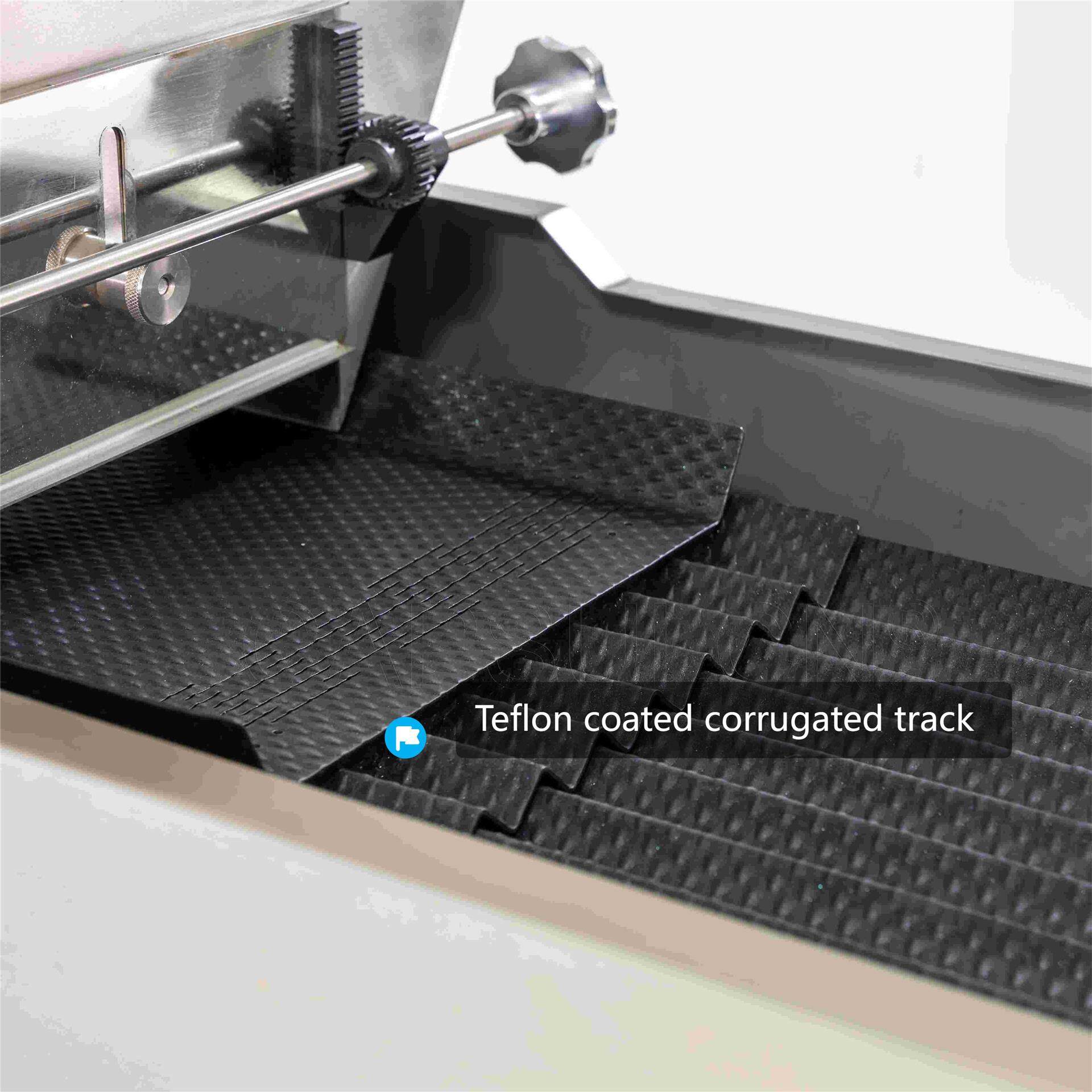

Teflon corrugated track has good anti-sticking properties, is easy to clean, has high wear resistance and corrosion resistance, and can be used for counting sticky objects such as soft candies.

Main features:

- Three-stage vibrators:With 8-channel vibration, materials are distributed more evenly.

- Reliable operation:It runs stably and smoothly with low noise.

- High dust resistance:It adopts unique anti-dust photoelectric sensor.

- Accurate counting:Due to photoelectric sensor detection and imported large PLC counting, bottle-filling error meets the international standard.

- Optional function:If special components are added, it can possess functions such as rejecting unqualified capsules or tablets and photoelectric detection alarming for lack of bottles or bottles being blocked.

- Simple operation:With intelligent design, various operating parameters can be set in advance, including at most 15 sets in memory.

- Easy maintenance:The operator only requires simple training as the disassemble, cleaning and replacement of parts are easy to carry out without the need of tools.

- Sealed and dustproof:It is equipped with a dust box to reduce dust pollution.

- The platform height can be adjusted according to the bottle height.

- The machine is equipped with a power supply voltage stabilizing system, so it can still work normally in areas with unstable power supply.

review(s)

Easy operation

The automatic capsule counting machine is easy to operate and accurate.

From: ruixue | Date: 3/2/2021 1:06 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche