Video

Introduction

The wide range of applications of metal detectors stems from their excellent performance, not only for bulk materials, but also for packaged products. It plays a key role in numerous industries, including food, medicine, plastics, chemicals, wood, textiles and more.

This equipment has excellent detection capabilities for metal impurities, whether they are magnetic or non-magnetic metals (such as iron, stainless steel, aluminum, etc.). Even if these metal impurities are hidden in product particles, they can be detected with a high degree of accuracy and Eliminate them ruthlessly by culling cells.

Companies shoulder important social responsibilities when using metal detectors. It helps implement a total quality management system (TQM) and plays an indispensable role in achieving ISO9000 international quality certification. In addition, it is also responsible for protecting subsequent machinery and equipment and ensuring product quality.

Specifications

| Model | CSJ-W150/200 |

|---|---|

| Channel diameter | 200*150mm

|

| Effective caliber | 120*170mm |

| Protection level | IP65 |

| Power supply requirements |

Good stable voltage, power supply should be wired separately to prevent electromagnetic interference from other electrical appliances, energy consumption is 0.2 kilowatts |

| Detection accuracy | Fe 0.7mm SUS 1.0mm NonFe 0.8mm |

| Equipment net weight | 120kg |

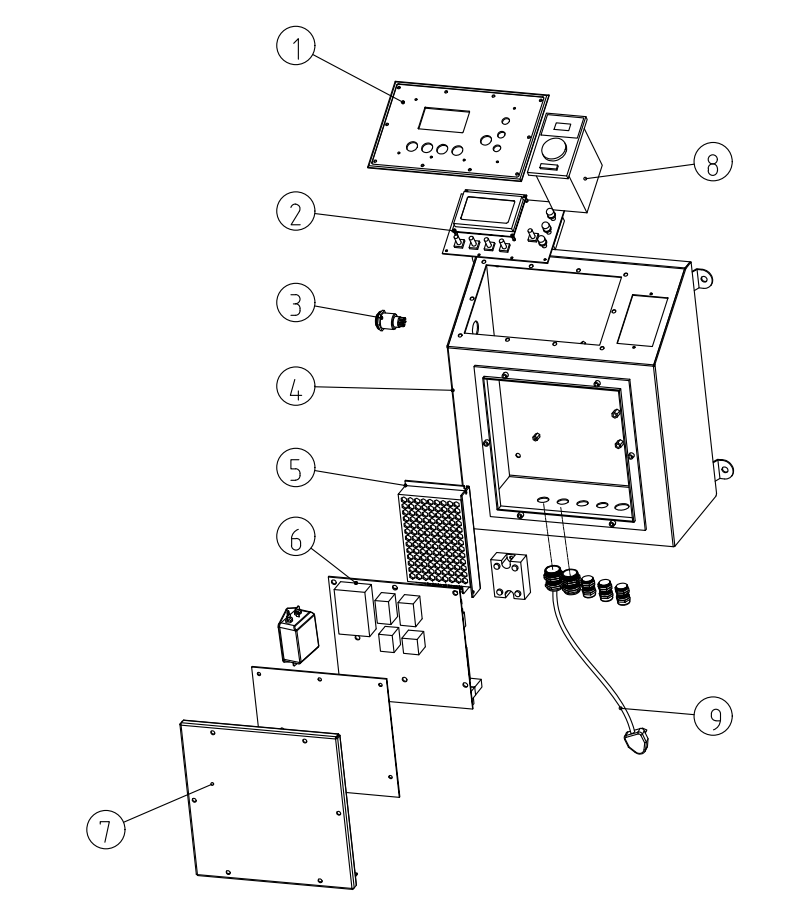

| 1.LCD screen cover | 2.Display board |

| 3.Switch | 4.Electrical control box |

| 5.Switch power supply | 6.Control board STE-M |

| 7.Electrical control box cover |

8.Motor controller |

| 9.Power wire |

10.Measurement board AWE-M |

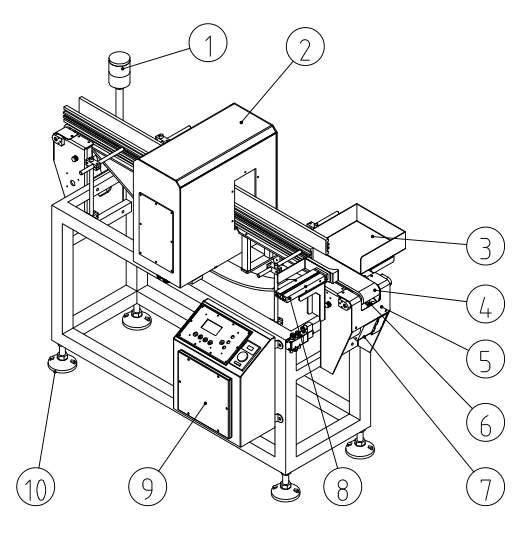

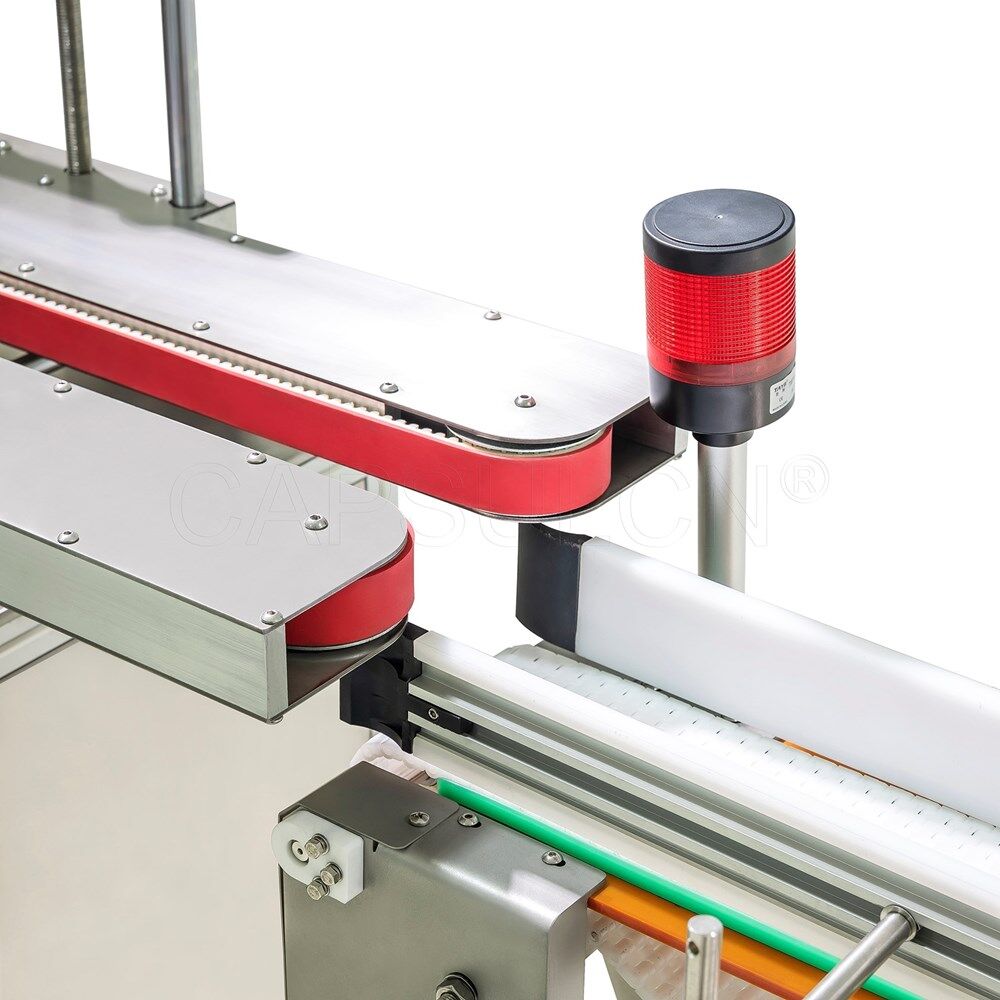

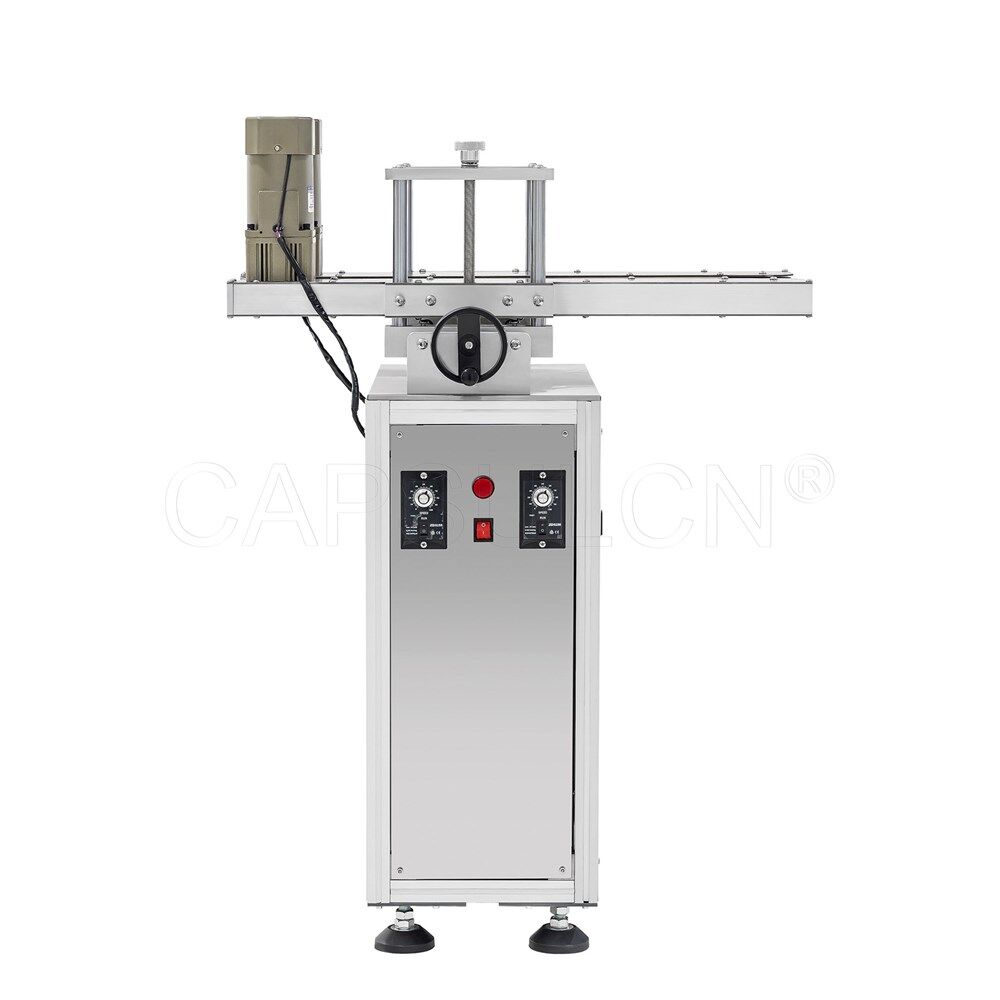

| 1.Alarm light | 2.Detection head |

| 3.Reject mechanism - temporary storage platform | 4.Chain conveyor belt |

| 5.Synchronous belt | 6.Synchronous wheel |

| 7.Motor |

8.Reject mechanism - cylinder |

| 9.Electrical control box |

10.Foot cup |

Maintenance

Before any maintenance and cleaning work, disconnect the power supply to the equipment, shut off the compressed air supply, and disconnect the air exhaust hose. Always adhere to safety precautions.

At appropriate intervals (e.g., weekly or monthly):

- Visually inspect all components disconnected from the product, such as belts, detection pipes, rejecters, drive components, etc., to ensure they are in normal condition.

- Replace worn parts to ensure the proper functioning of the equipment.

- Check all screws and nuts for tightness when necessary.

- Clean the channels regularly to ensure there are no metal impurities, as this could lead to false alarms.

Remark

- Regular inspection of the metal detector is crucial for ensuring safe operation.

- Use appropriate metal test balls to test the metal detector. If the metal detector is operating normally, it will emit a metal detection signal.

- It is recommended to perform a performance check every two weeks.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

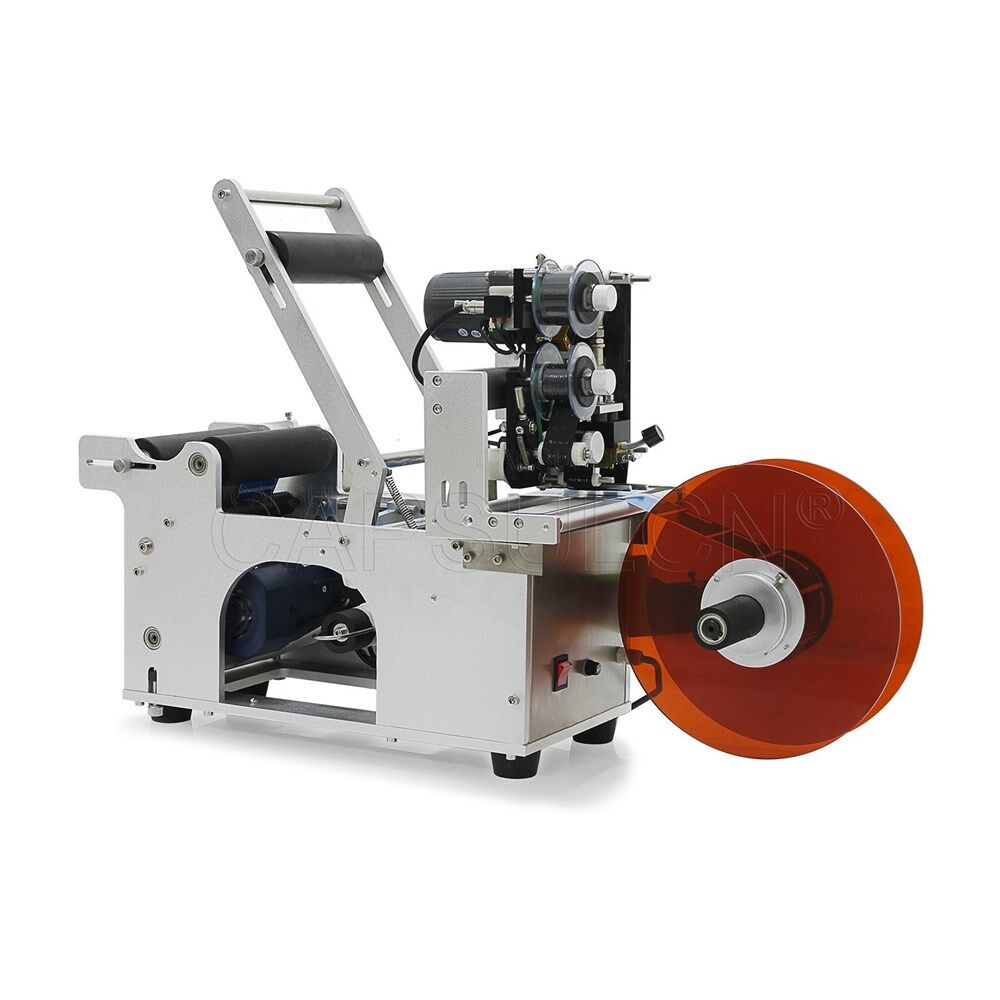

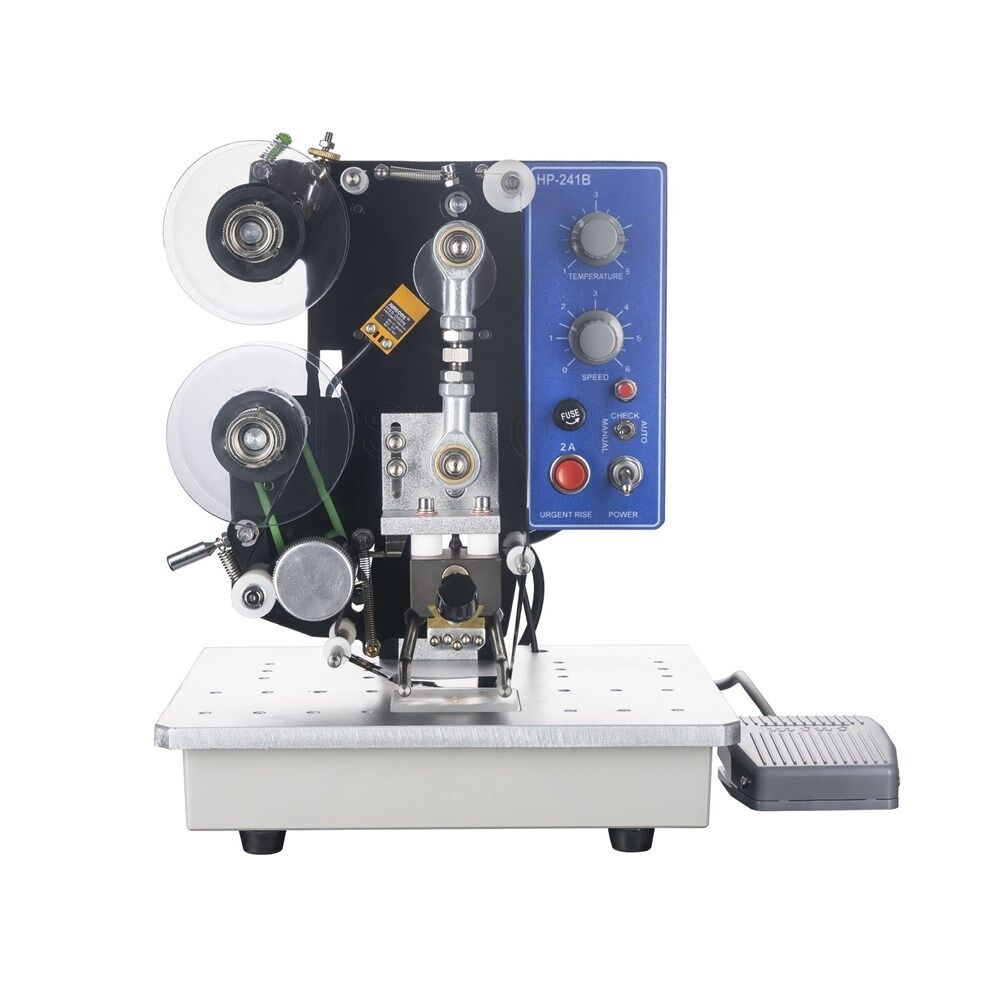

Hot Ribbon Coder Printer HP-241B

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche