Video

Introduction

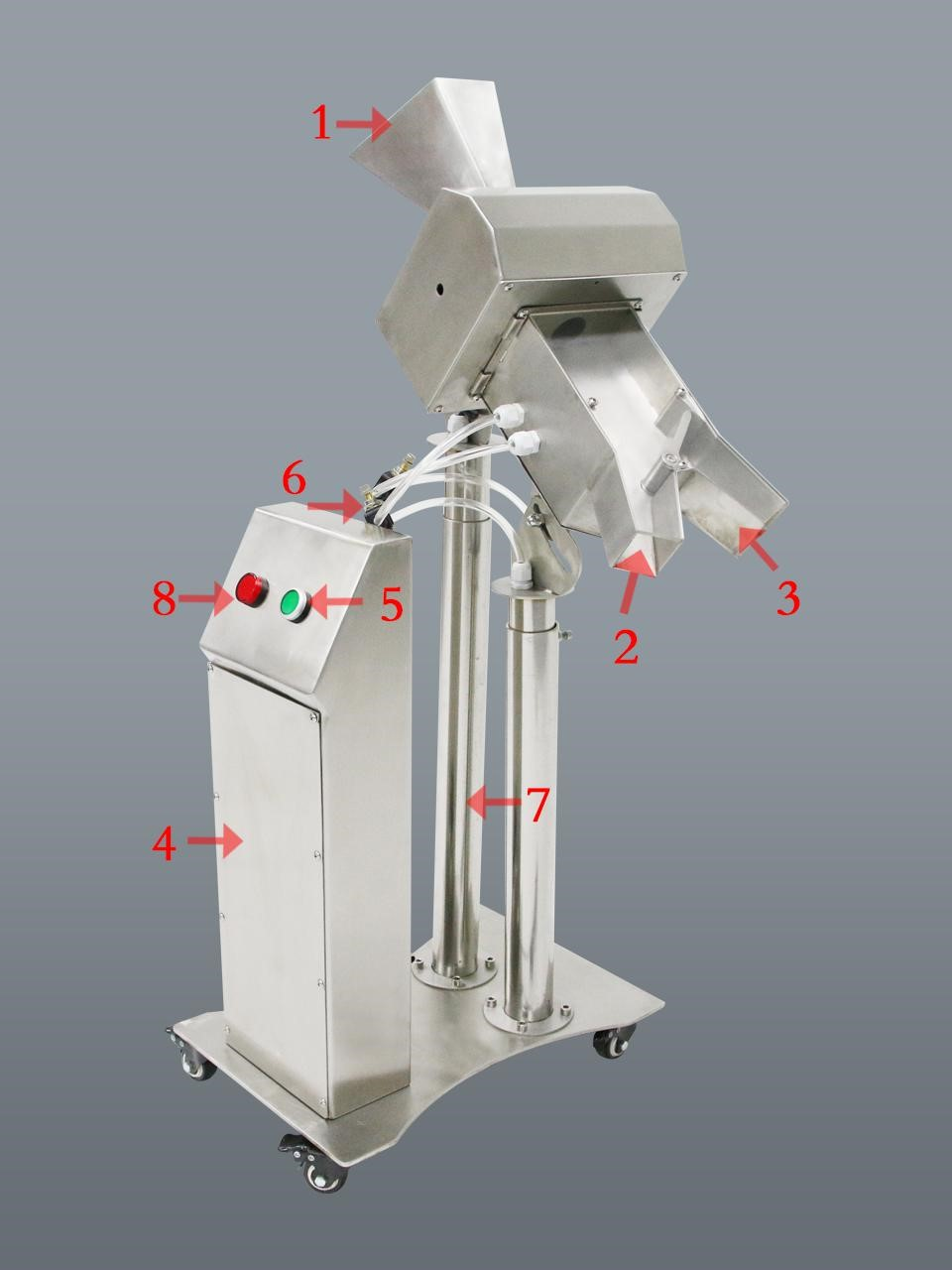

1. Material inlet 2. Foreign matter discharge port 3. Normal material outlet 4. Electric box 5. Main power switch 6. Air regulating valve 7. Bracket 8. Alarm indication

Installation conditions

- Places where the temperature is no less than -20℃ and no more than 60℃.

- A place where the humidity is within the range of 30~85% and there is no condensation.

- No direct sunlight, and no heating appliances such as stoves and heaters nearby.

- The power supply voltage fluctuation range does not exceed +10% and -15%.

- Away from vibration sources and in a place where vibration is unlikely to occur.

- A place with less dust.

- A place free of volatile flammable substances, corrosive gases and salt water.

- Stay away from strong electromagnetic fields.

Operate

The metal separator can be installed directly on top of the feed pipe of the equipment; the sensor faces up and the output pipe faces down.(feeding by gravity)

The hole in the mounting plate at the lower end of the metal separator should be consistent with the hole in the feed pipe, and then the mounting plate is fixed on the equipment.

The holes in the upper mounting plate of the metal separator should match the holes in the feed hopper and mixer so that this device can be directly mounted on the metal separator.

The cylinder requires 2.5-4.5 kg of compressed air to operate properly. In order to achieve the best working condition, the compressed air must first pass through the water separator and oiler.

Metal separator needs: single phase 220V/50-60Hz power supply.

Remark

- The power plug must be unplugged when cleaning.

- A cleaning tool such as a soft plastic brush or cloth should be used. Never use metal brushes, etc.

- Use neutral detergent for cleaning. Never use organic solvents such as thinner and benzene.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

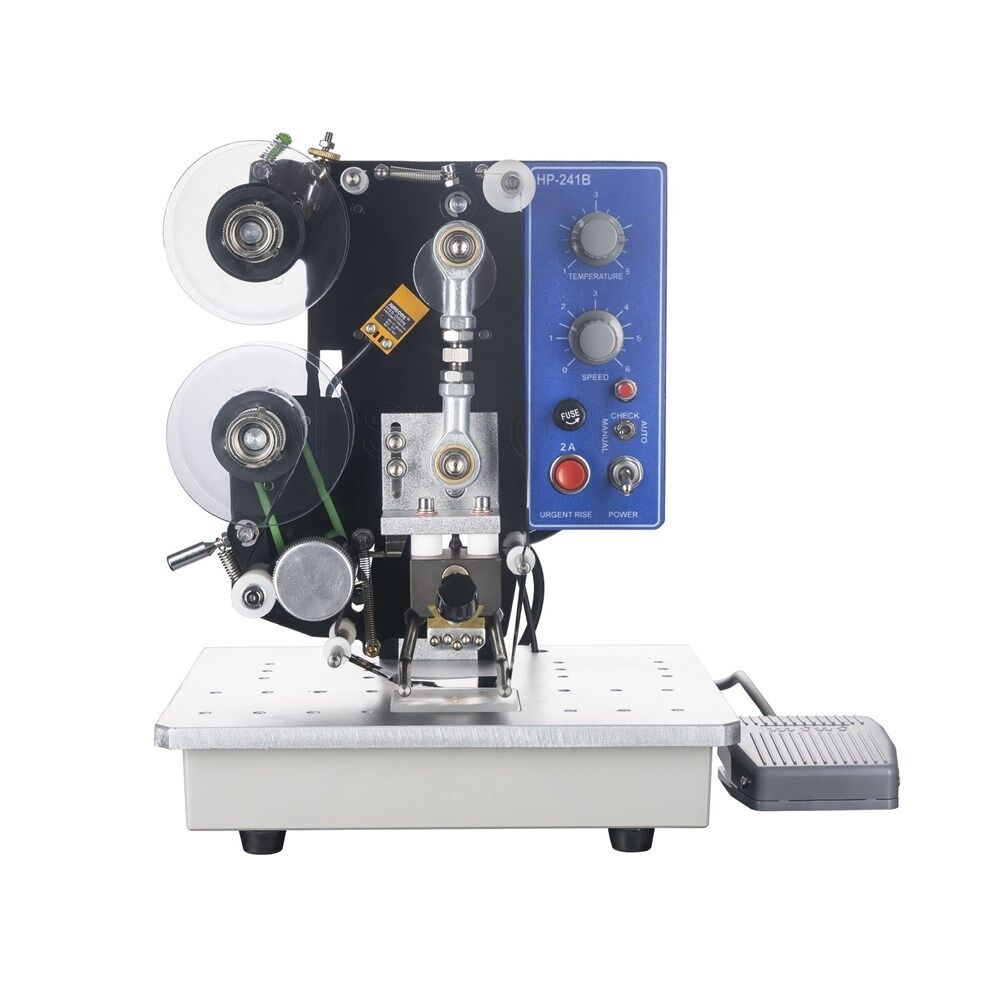

Hot Ribbon Coder Printer HP-241B

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche