Introduction

This machine adopts programming control system, touch panel operation, stepless frequency conversion speed regulation, pneumatic joint control, and electronic automatic counting device, which can automatically complete the capsule positioning, separation, filling, locking and other actions. The filling dose is accurate and the operation is convenient. The body and work surface are made of stainless steel, and the product meets the requirements of GMP. It is suitable for capsule filling of powdered and granular medicines.

Specifications

| Model | JTJ-V Pro 5 |

|---|---|

| Output | 1-42000 pcs/hour |

| Applicable capsules | 00#,0#, 1#, 2#, 3#, 4# |

| Total power | 4 kw |

| Vacuum pump(evacuation rate) | 40m3/h |

| Air pressure | 0.03m³/min,0.7MPa |

| Dimensions(LxWxH) | 1140*700*1630mm(L*W*H) |

| Whole weight | 330kg |

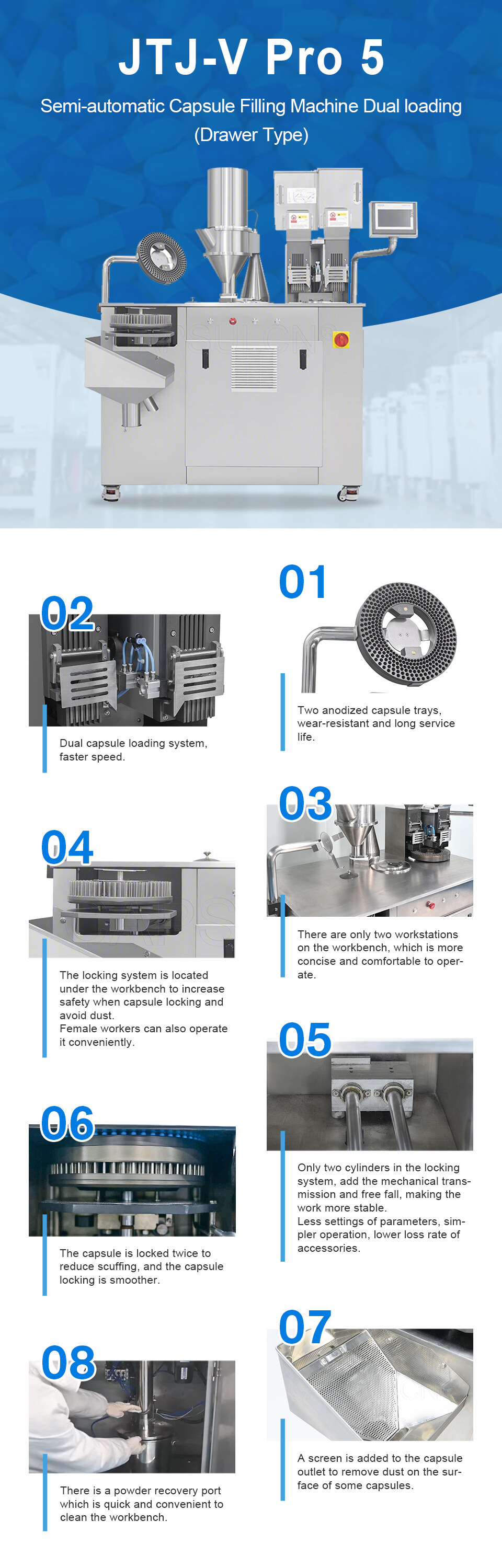

Advantages

Practicality upgrades

- Use external hexagon screws:more convenient to clean,solves the cross-contamination of materials.

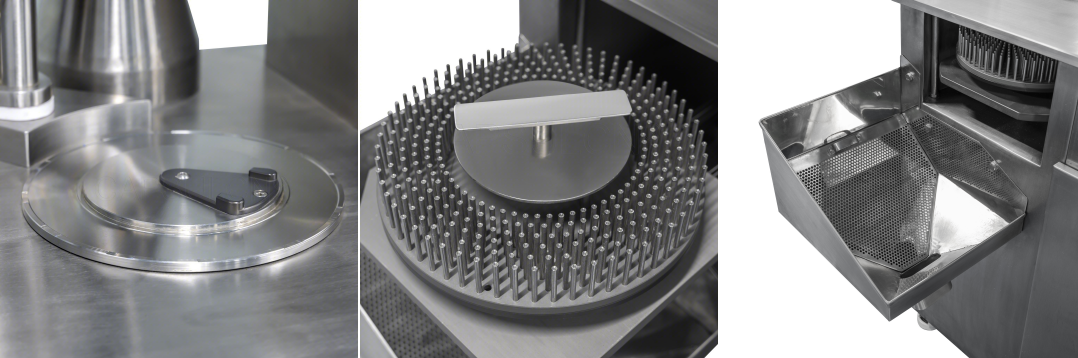

- Use oxidized capsule tray: A protective film is added to the surface to enhance the corrosion resistance, surface hardness and wear resistance of the surface layer, prolong the service life of the grinding disc, and is easy to clean.

- The installation of the main power switch can directly cut off all work, without powering off to open the electrical box and then turn off the power.

- The position of the emergency stop button has been changed, you can reach out and touch it. It's easier to deal with in case of emergency.

- The discharge port is designed to be detachable, which solves the problem of difficult cleaning of material residues at the discharge port; a new mold tray rack is installed to make the operation of multiple trays more convenient.

review(s)

Very convenient!!

This machine is easy to operate and safe, cleaning is also very convenient!

From: Yirui | Date: 4/8/2022 1:27 AM

Write your own review

Also Offers

Related products

Automatic Capsule Filling Machine NJP-3500C

Semi-auto Capsule Filling Machine JTJ-V Pro+

Semi-Automatic Capsule Filling Machine JTJ-V Horizontal Type

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche