Introduction

This machine is designed and developed by the professionals in compliance with the industry standards. Owing to the attributes such as durable finish standards, high load bearing capacity, low maintenance cost and robust construction, these machines are widely appreciated in the market.

Main application:

CGP-100 automatic filming machine is mainly used in medicine, industry, chemical industry, food and other industries.

CGP-100 automatic filming machine is mainly used in medicine, industry, chemical industry, food and other industries.

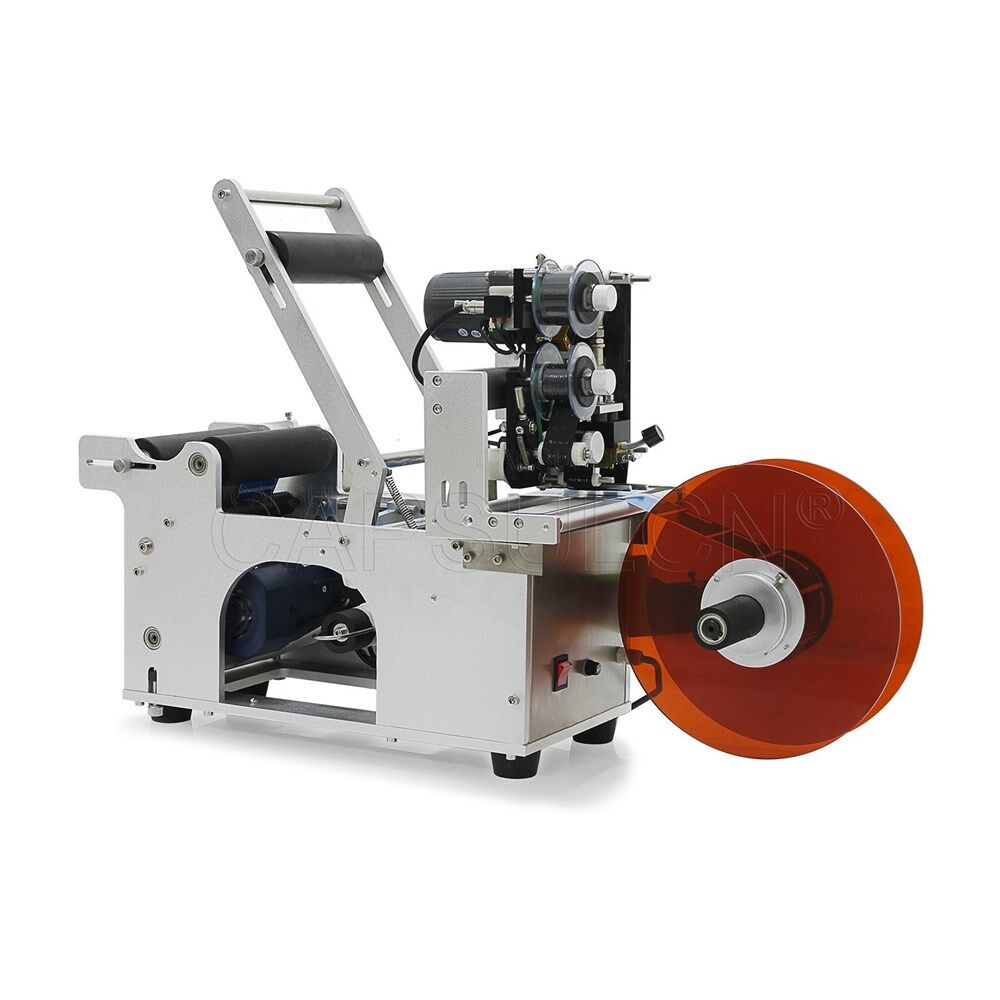

CGP-100 Automatic Sleeve Labeling Machine

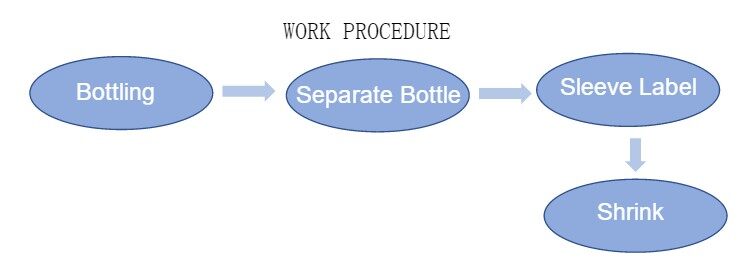

CGP-100 automatic film covering machine is a fully automatic intelligent packaging line, which integrates

bottling,separating, labeling, shrinking and other functions. Real high speed, precise positioning, reduced manpower and perfect packaging are the spirit of the equipment design. Beautiful, easy to clean and maintain.

bottling,separating, labeling, shrinking and other functions. Real high speed, precise positioning, reduced manpower and perfect packaging are the spirit of the equipment design. Beautiful, easy to clean and maintain.

Feature:

*The whole machine is made of aluminum alloy with anode treatment and 304 stainless steel material to support the host and fix the conveyor belt.

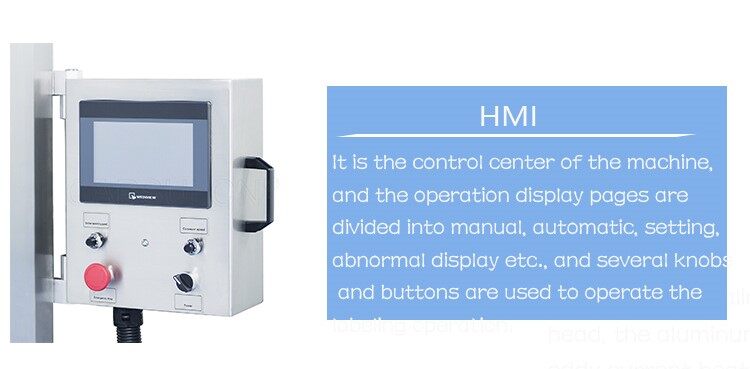

*This set of equipment adopts advanced technology, adopts large-screen touch screen PLC program controller or relay control, the packaging process is controlled accurately, the whole machine runs stably, and the performance is reliable.

*This set of equipment adopts advanced technology, adopts large-screen touch screen PLC program controller or relay control, the packaging process is controlled accurately, the whole machine runs stably, and the performance is reliable.

Advantages:

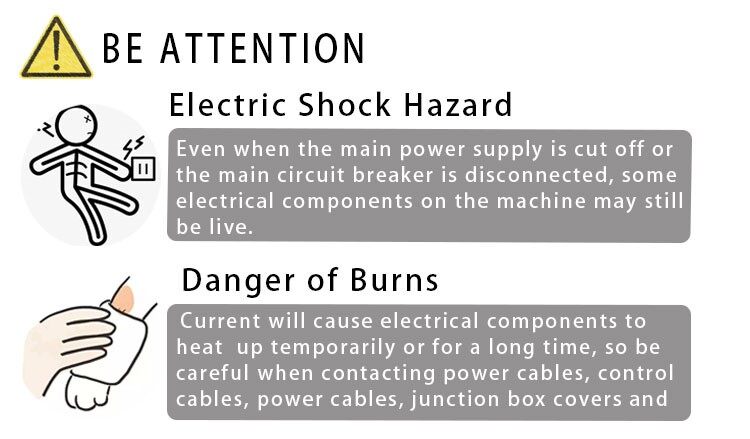

In order to enable the operator and the machine itself to function more safely and effectively, the machine adopts

advancedtechnology to set up a number of automatic protection measures to ensure the safety of the machine and the operator.

advancedtechnology to set up a number of automatic protection measures to ensure the safety of the machine and the operator.

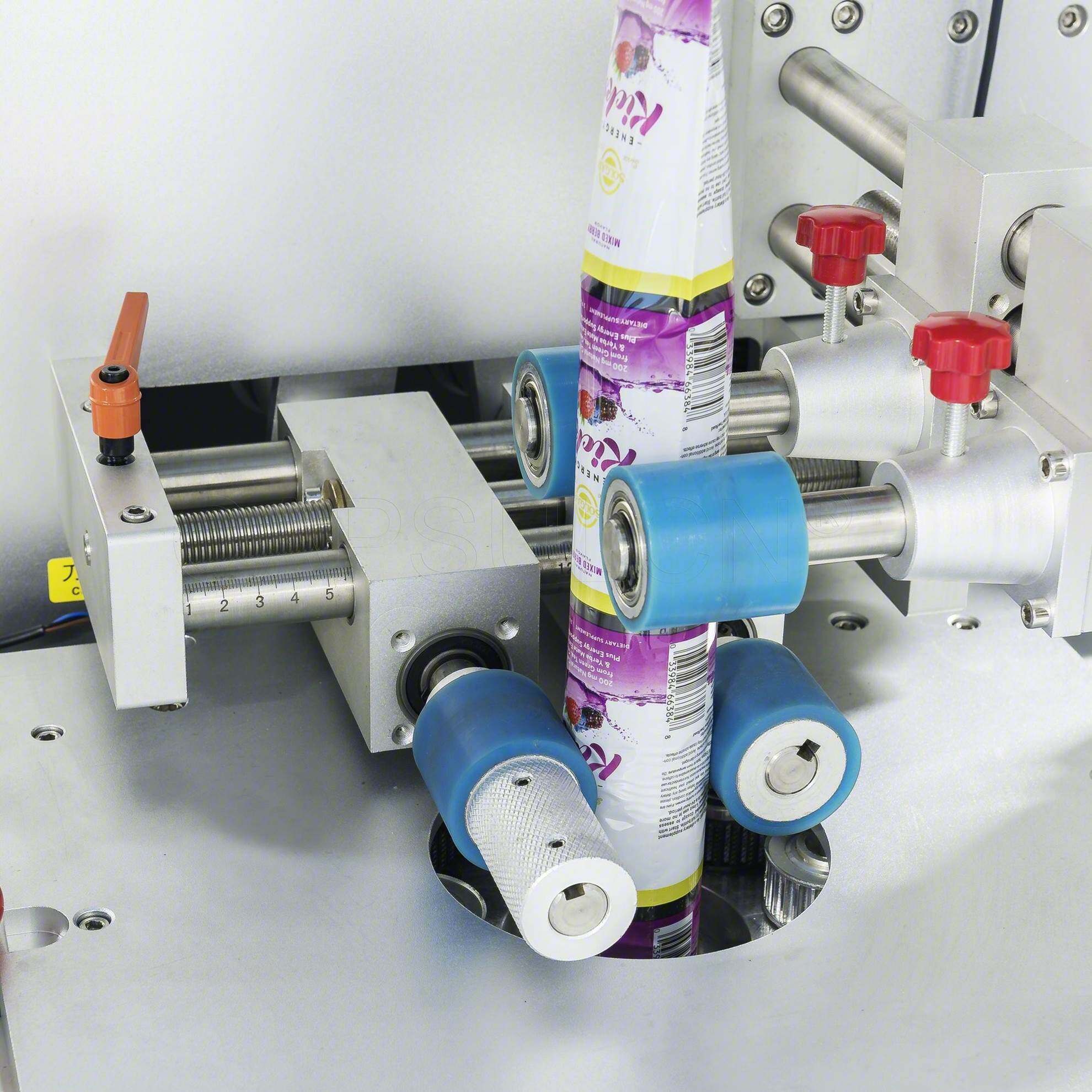

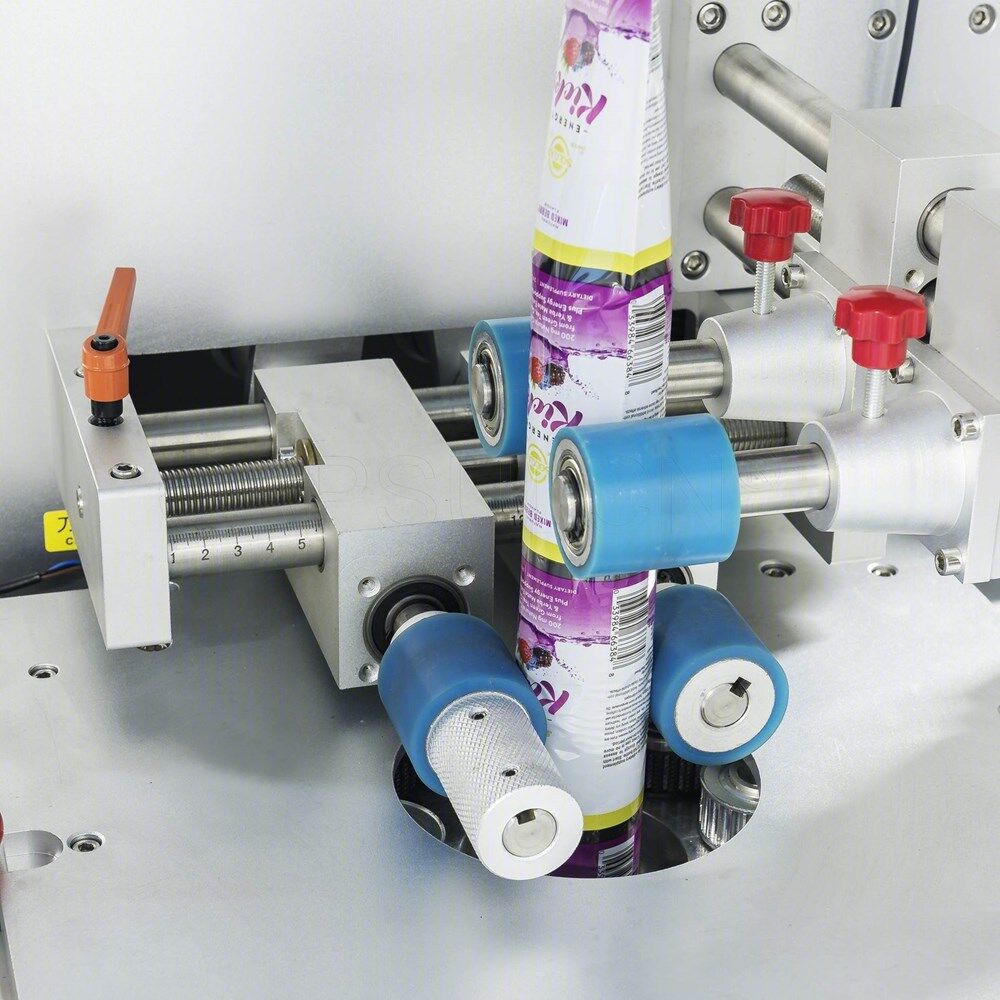

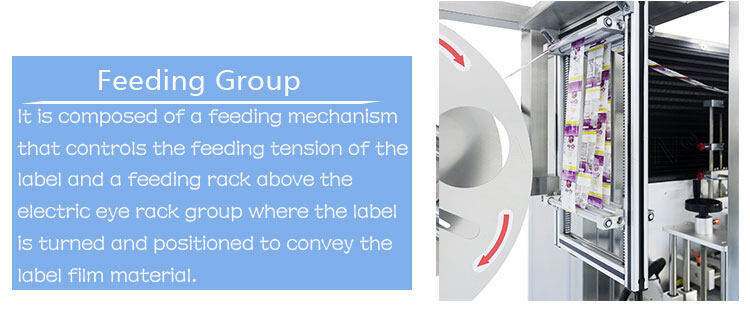

Details Images

Specifications

| Model | CGP-100 |

|---|---|

| Bottle diameter | 30mm~100mm |

| Label size | 30mm~180mm |

| Label thickness | 0.035mm~0.13mm |

| Output | 100 bottle/min |

| Label reel | Inner diameter 76mm |

| Power | 3KW |

| Voltage | 380V/220V 50Hz 60Hz |

Remarks

- It can be operated independently or as part of your existing production line.

- Adjustable feeding sensor, precision lock up sleeve.

- Whole machine malfunction automatically detect, timely find out equipment failure reasons

- The advanced operating system, colorful touch screen is more human being

- Servo motor and high-delicacy photo-electricity make the cutting label precise

- High-normal electric, the feeding cutter co-ordinates flawlessly thereby allow smooth feeding.

review(s)

Best

The speed is very fast and the packaging of things is also very standard

From: Chius | Date: 3/3/2021 9:10 PM

Was this review helpful?

(0/0)

Write your own review

Also Offers

Big Promotions

Containment Automatic Capsule Filling Machine SFK-703

Call for Quote

Fully Automatic Dosator Capsule Filling Machine CZ-40

Call for Quote

Related products

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche