Introduction

- Bottle unscrambler——Auger filling machine——Capping Machine——Induction sealing machine——Labeling machine——Bottle unscrambler

- Powder filling line can be used in medicine, industry, chemical industry, food and other industries.

High-speed Automatic Bottle Unscrambler

- This machine is suitable for round /spare ( PE,PP,PS,PET) with different sizes in the pharmaceutical industry.

- Photoelectric detection function: detecting whether there is blocking on the conveyor belt behind.

- High bottle loading rate: using the automatic reverse bottle mechanism and the reverse bottle blowing device to blow the unqualified bottles back into the bottle sorting tray.

|

|

Automatic Auger Filling Machine

- This machine is a complete, economical solution to your filling production line requirements.

- It fits more to the fluidic or low-fluidity materials, like milk powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on.

- Stainless steel structure; The quick disconnecting hopper could be washed easily without tools.

- PLC, touch screen and weighing module control.

- Replacing the auger parts, it is suitable for material from super thin powder to granule.

- Include handwheel of adjustable height.

|

|

Fully-automatic Capping Machine

- Wide range of applications, apply all different round, rectangular and most irregular bottles and containers.

- Good capping effect: The capping wheel is made of new silicone material, which fits better with the bottle cap, and the capping wheel has a long service life.

- The capping speed is 3-4 times higher than the traditional claw capping machine, and it can effectively prevent common defects such as burrs on the bottle body and bottle cap breakage.

|

|

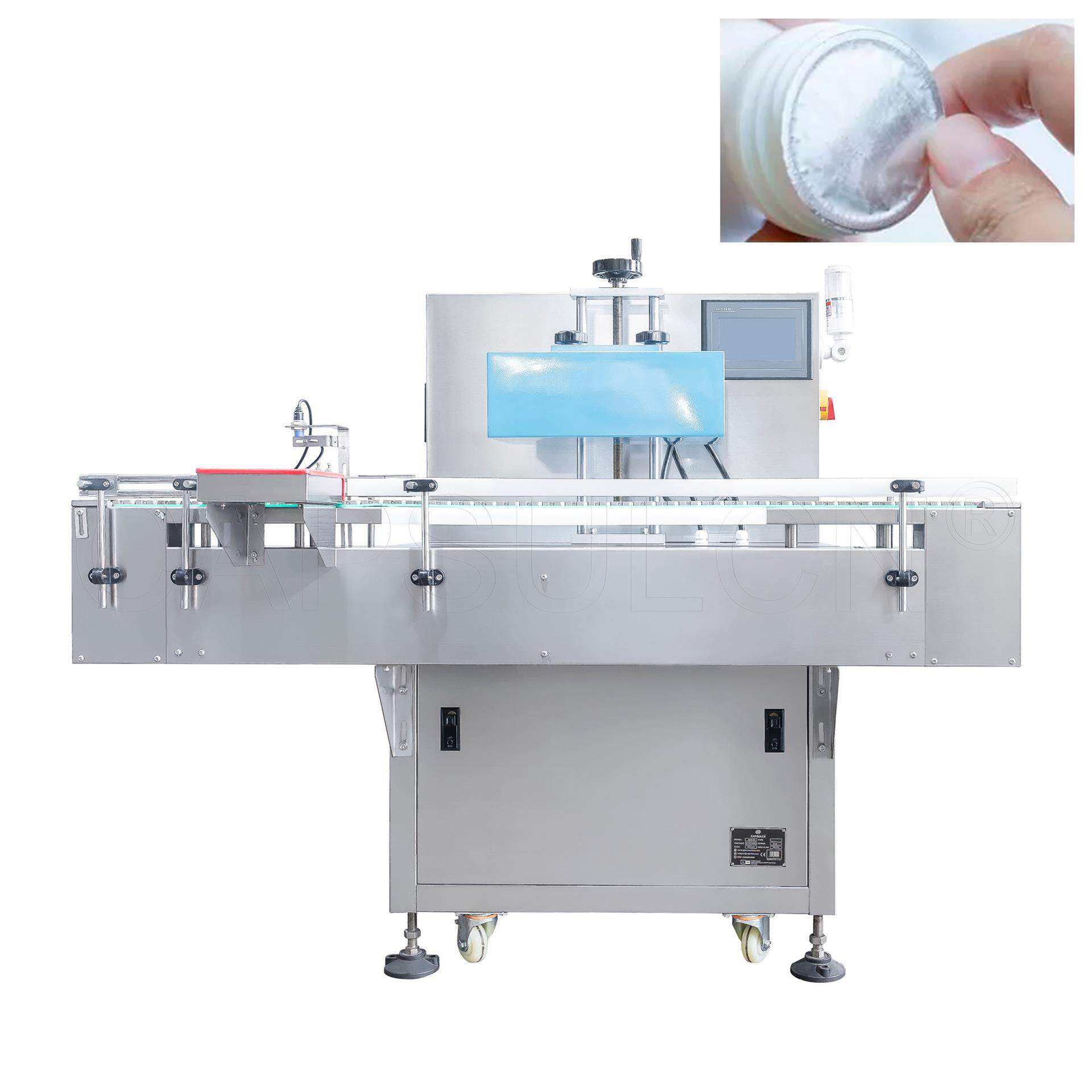

Induction Sealing Machine

- The induction heating head adopts the circulating water to cool.

- The machine is suitable for sealing the caps of all round bottles and some special-shaped bottles with aluminum foil, and the finished product rate of aluminum foil sealing basically reaches 100%.

- The unique structure of the tunnel induction head, electrical modular control, better stability, and stronger sealing.

- The purpose is to make the products in the container are moisture-proofed, mildew-proofed and anti-counterfeiting.

|

|

Self-adhesive Labeling Machine

- The label feeder is controlled by the servo motor of Japan's Panasonic, the label does not slip. The label feeding precision is high, and the label position can be adjusted.

- A linear roller device is added to prevent labels from falling off and being broken, which improves production efficiency.

- The new high-speed coding machine has strong applicability, thermal code printing, and clear and beautiful fonts. The coding position can be adjusted within a 360-degree range. It can be printed horizontally and vertically.

|

|

Bottle Turntable Unscrambler

- Manually put the bottle neck up on the tray, and the bottle will automatically enter the conveyor belt of the next link. The turntable unscrambler has a wide range of applications.

|

|

Write your own review

Also Offers

Big Promotions

Containment Automatic Capsule Filling Machine SFK-703

Call for Quote

Fully Automatic Dosator Capsule Filling Machine CZ-40

Call for Quote

Related products

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche