Also bought

Introduction

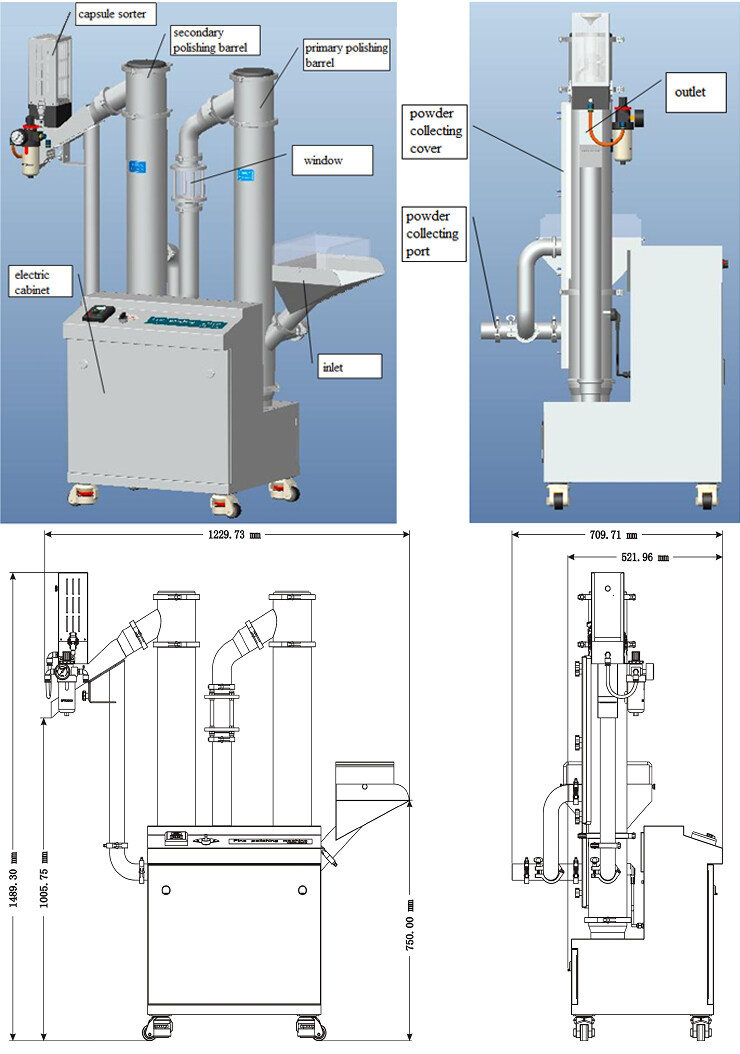

LSV-C200 Capsule Polisher has achieved double functions of capsule polishing and elevating. Inlet of the machine can be connected with any model of capsule filling machine, and outlet with capsule sorter and metal detector, so that to realize the production line of capsule polishing, elevating, sorting and detecting.

Specifications

| Model | LSV-C200 |

|---|---|

| Capsule Model No. | 00# 0# 1# 2# 3# 4# |

| Max Output Capacity | 600,000pcs/h |

| Power Supply | 1PH 220V/110V 50Hz/60Hz 0.2kW |

| Compressed Air | 0.3m3/min 0.3MPa |

| Vacuum | 2.7m3/min -0.1MPa |

| Inlet Height | 750mm |

| Inlet Hopper Size | 300x250mm |

| Outlet Height | 1005mm |

| Outlet Hopper Size | 65x50mm |

| Dimension | 1229x709x1489mm |

Remarks

Designed with up-to-date concepts and adopting several advanced technologies, the machine is equipped with following characteristics:

- Double functions of capsule polishing and elevating to leave high flexibility for follow-up equipment line;

- 360° circle adjustment for inlet and outlet to make production more convenient and save factory room;

- Automatically sort less dosage, empty, fractured and cap-body separated capsule;

- Fast-joint system to ensure safe and quick disassembly and assembly;

- Parts in contact with medicine all made of 316L stainless steel or other material conforms to modern medicine safety standards;

- Detachable brush on main shaft can be thoroughly cleaned. No blind spot during whole machine cleaning. Meet cGMP demands.

review(s)

GOOD

This machine is really great, it saves a lot of effort

From: Isabella | Date: 3/1/2021 3:17 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Capsule Sorter & Polisher HSLC100

Capsule Polishing Machine YPJ-III

Automatic Capsule Filling Machine NJP-3500C

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche