Auger Powder Filling Machine HZF-C: Inspection and adjustment

The parts of the equipment have been adjusted before leaving the factory. However, during transportation and handling, the fasteners may loosen and cause position changes. In addition, the relevant parts need to be adjusted when replacing the filling parts. And adjustments should be made to the Powder Filling Machine before the official use:

The inspection contents include:

1. whether the electrical connectors are reliable and the fasteners are loose.

2. Is there any foreign matter in the hopper?

3. Whether the operating parts are damaged.

4. The direction of rotation of the agitator is correct (clockwise from top to bottom). If the direction is not correct, you can exchange any two wires of the stepper motor power supply.

5. Adjust the shaft screw for looseness.

6. Hopper is concentric with the screw. The inspection method is:

Loosen the hopper fixing screw and remove the hopper. Every 90 degrees of rotation of the bay, nested into the hopper to observe whether interference, such as not concentric must be adjusted.

Adjustment

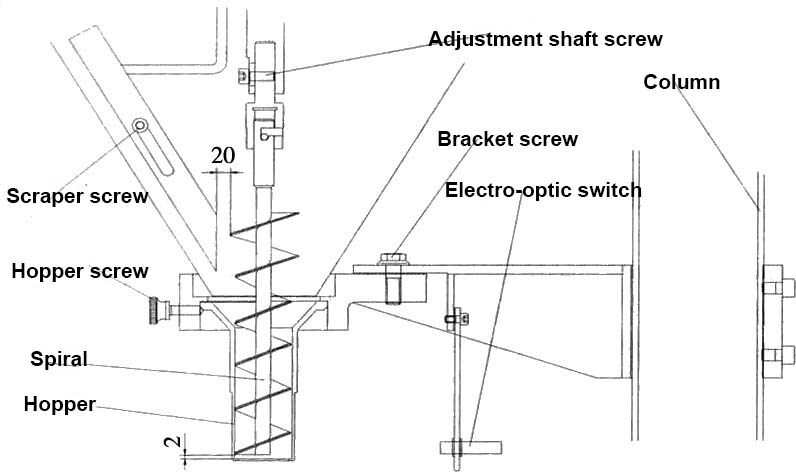

Adjustment of the hopper holder

Hang the screw on the adjusting shaft, put the hopper on the screw every 90° of the spiral, and observe the gap between the hopper and the fixed seat. If the gap is inconsistent, adjust the holder First loosen the rod clamp (do not loosen completely, use a wooden stick to knock the bracket), use a wooden stick to hit the position of the fixed seat gap, and smoothly put the hopper when the screw is turned to any position. The position has been adjusted to tighten the rod clamp.

Adjustment of screw height

The hopper is placed on the screw to observe the position of the bottom of the screw, and the bottom of the hopper is about 2 mm from the inner edge of the bottom of the hopper. When adjusting, open the observation window on the right side Of the hopper cover, loosen the adjusting shaft screw, fix the cup with three hopper screws evenly, Hold the adjustment shaft up and down by hand, and tighten the adjustment shaft screw when the screw height is appropriate.

Adjusting the position of the scraper

The agitator blade should be adjusted when changing the screw. The position of the blade from the screw is usually around 20 mm. Loosen the scraper screw while adjusting, and tightening the pull-up or push-down scraper screws.

Adjustment of photoelectric switch

The sensitivity of the photoelectric switch has been adjusted at the factory, and it can be adjusted if it feels inappropriate. Use a screwdriver to rotate the screw at the rear end of the photoelectric switch, and at the same time block the photoelectric switch by hand At this time, the red light will be on until the distance is appropriate.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche