Bottle Capping Machine Parts: Everything You Need To Know

For most people, capping a bottle sounds like an easy task. However, if you need to cap hundreds of bottles, it can be overwhelming. At this point, you may need to use a machine, such as a bottle capping machine. It will help you to improve the efficiency of your capping process.

Parts matter a lot for any machine. Capping machines are no exception. So, in this article, we will walk you through everything you need to know about bottle capping machine parts. Without further ado, let's get to the point.

What is a Bottle Capping Machine?

A bottle capping machine is one of the most common devices on a packaging line. Its main function is to cap containers. These containers come in a wide variety, from medicine bottles to beverage bottles, but all these are just a piece of cake for a capping machine.

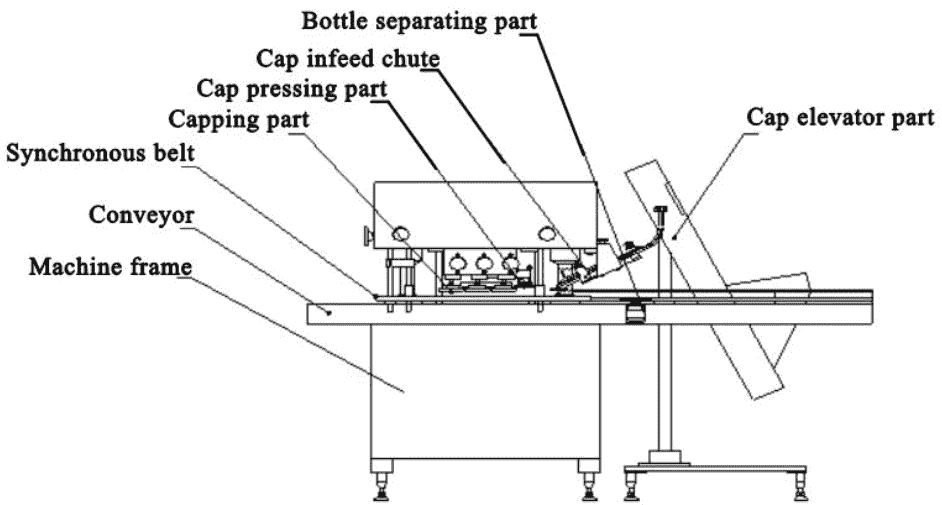

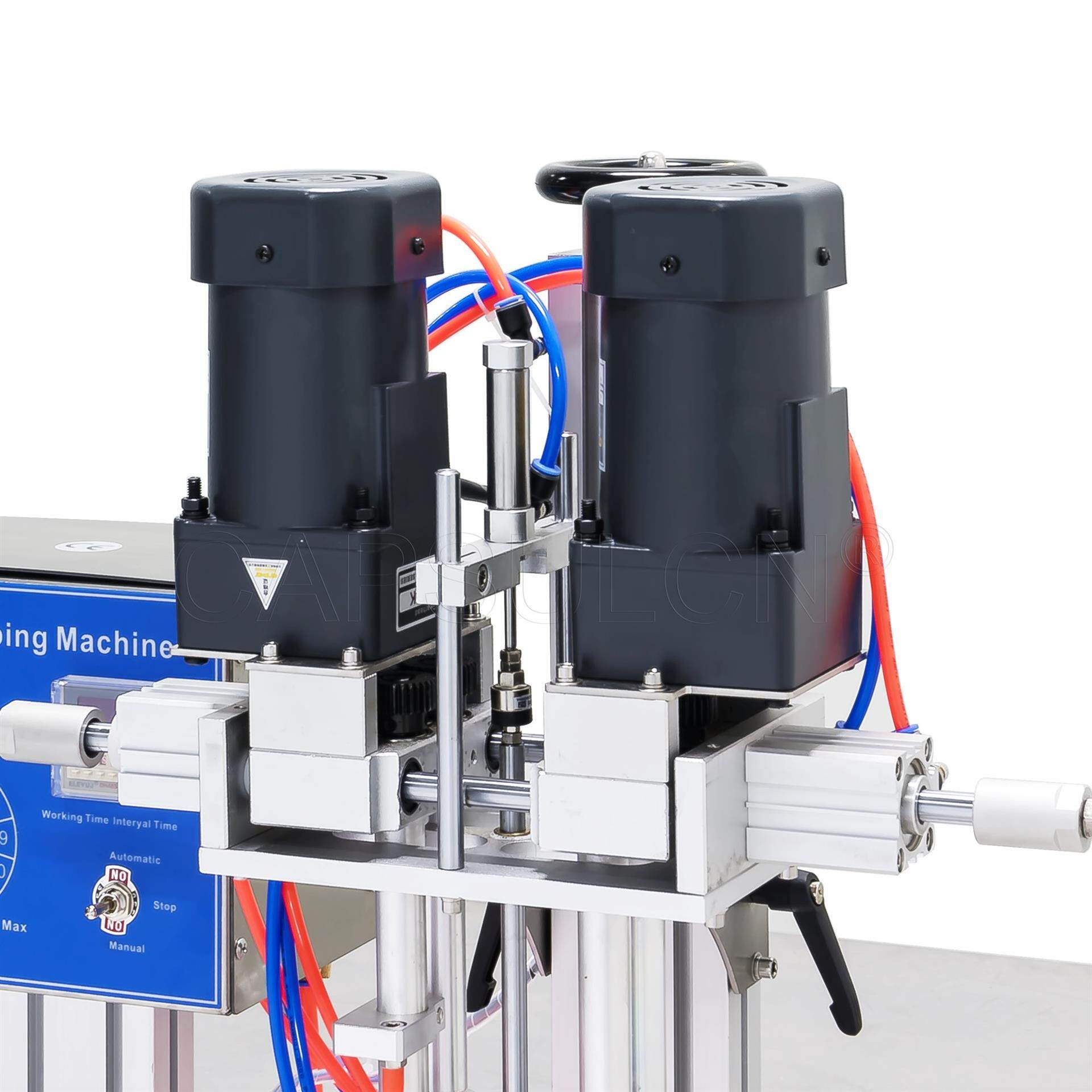

Automatic Bottle Capping Machine Diagram

There are several types of bottle cappers. The automatic bottle capping machine is the most popular type among them. Before we explore the capping machine parts, let's look at the entire machine.

What are the Main Parts of a Bottle Capping Machine?

A bottle capping machine consists of many parts, and each of them cannot be ignored. All these parts work together so that the machine can run efficiently. Well, let's take a closer look at these parts and their functions!

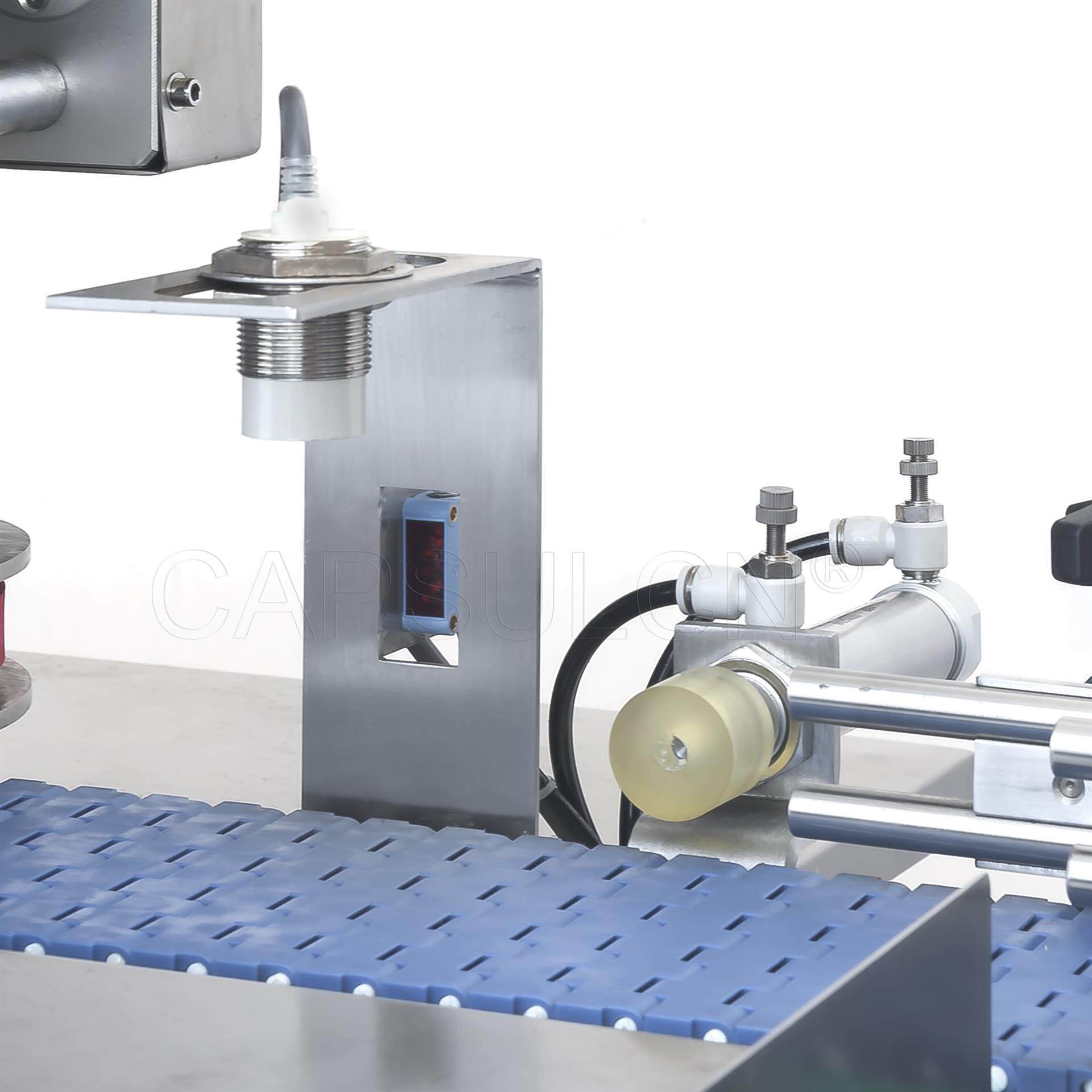

Conveyor Belt

You will find a conveyor belt in every automatic bottle capping machine. This device may seem ordinary, but it actually plays an important role in the entire capping process. As a conveyor, it is responsible for delivering each container to the right place. With it, your containers will always remain stable during the capping process.

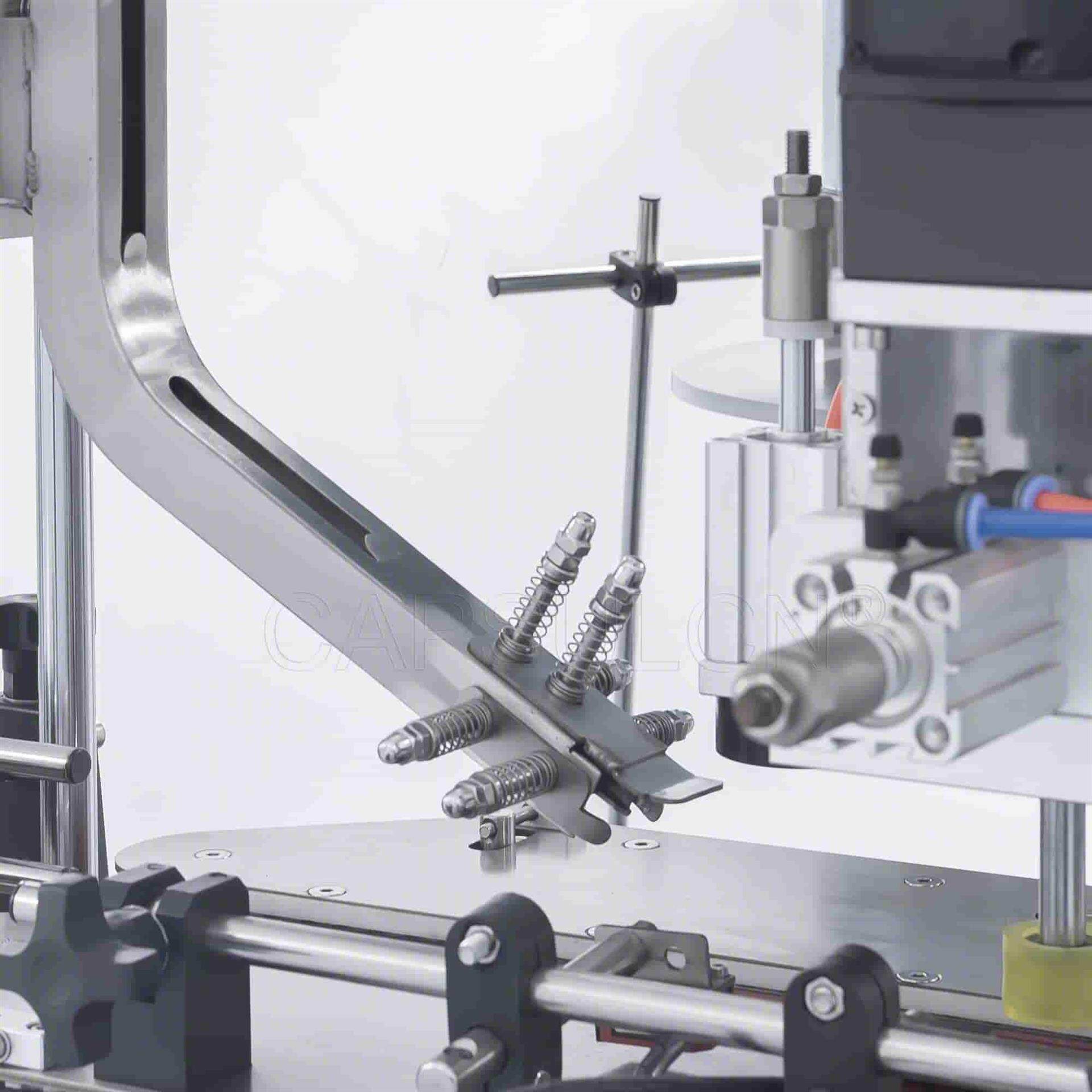

Cap Feeder

The cap feeder is a vital part of the bottle capping machine. A conveyor belt first transports the bottles to the cap feeder, where the caps are initially placed on the bottles.

There are normally three important elements of the cap feeder:

1. Chute

It is usually an inclined channel that looks a lot like a slide in a kindergarten. You know why a design like this? The inclined design makes it smoother for the caps to reach the container. Also, it also acts as a guide for the caps. Thanks to it, the cap will never get lost.

2. Hopper

It holds a bunch of caps that need to be pressed onto bottles.

3. Sorter

When your caps come in different shapes or sizes, you may use a sorter. It is useful for picking out qualified caps.

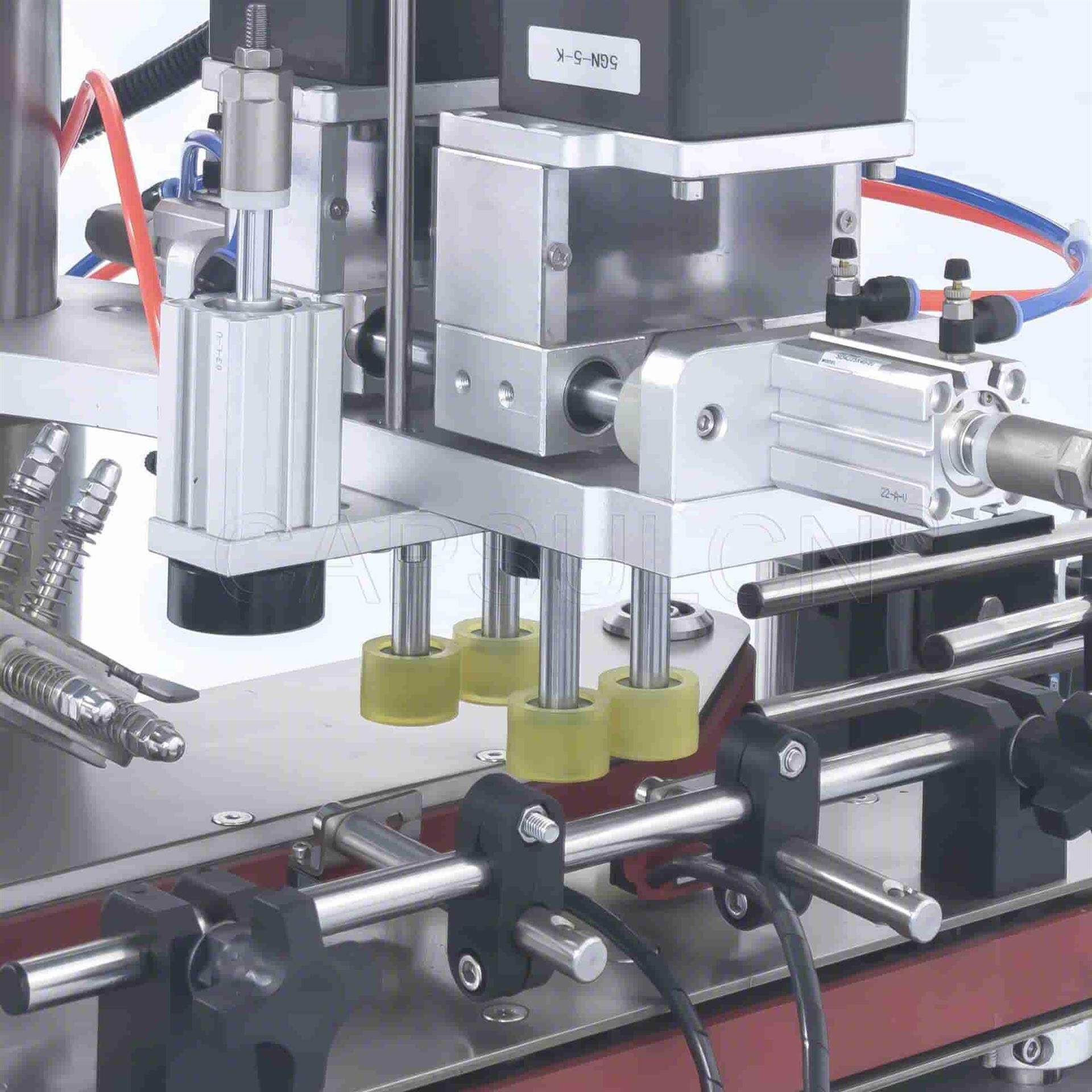

Cylinder

The cylinder is one of the important parts of a bottle capping machine. Its primary role is to provide the required force for tightening the bottle caps. Not only that, it also helps in closing the snaps on various kinds of bottle caps.

Capping Station

The capping station is the centerpiece of the cap screwing machine. It is where the actual capping process takes place. At the capping station, the capping head does the most important work. Normally, it consists of a chuck or gripper plus a spindle. The gripper is used to hold the cap securely. Meanwhile, the spindle tightens the cap onto the bottle neck.

Control Panel

The control panel is where you operate and monitor the capping machine. It makes it easier for you to control the entire machine. There are a series of parameters on the control panel, and you can adjust them as needed. More importantly, it helps you troubleshoot potential problems in the capping process.

Motor

As an integral component of the bottle capping machine, the motor powers the whole capping process. In addition to this, it somehow guarantees the stability and precision of the machine. Usually, the motor powers the capping head through a gearbox or other device. This collaboration between the motor and other components makes a bottle capper run smoothly.

Understanding Different Types Of Bottle Capping Machine

If you are trying to start your own pharmaceutical business, a reliable bottle capping machine is what you need. However, there are so many types of bottle cappers. By automation, you will find three main types: manual, semi-automatic, and fully automatic. To help you make a better choice, we'll go over each type in detail.

Manual Bottle Capping Machine

A manual bottle capping machine, also known as a handheld bottle capper, tightens bottle caps onto containers.

A manual bottle capper is quite simple to use. First, you can put the bottle on a flat surface and then lay the cap on the bottle. After that, press the lever, and the cap will be tightened onto the bottle.

A handheld capping machine is a relatively inexpensive solution for capping bottles. It may not work as fast as semi-automatic and fully-automatic machines, but it is cost-effective. So, it's good enough for companies on a tight budget.

Semi-Automatic Bottle Capping Machine

A semi-automatic bottle capping machine perfectly combines manual and automation to realize bottle capping. In general, its performance is better than the manual capper, while the price is lower than the fully automatic one. Also, it can fit all types of containers. So, a semi-automatic bottle capper can be a great choice for medium-sized company.

Semi-automatic bottle cappers are typically table-top machines. When operating a bench top capper, you should first snap the cap onto the filled bottle and then place it under the chuck head. Next, set the gears to manual mode. For the final step, you just need to press the foot pedal switch and the machine will begin its bottle capping process.

Automatic Bottle Capping Machine

Obviously, an automatic bottle capping machine is a super smart and labor-saving device. That is why it has been popular in today's packaging industry.

What may surprise you is that an automatic capping machine can handle hundreds of containers per minute. Besides, this machine ensures accuracy and high quality while keeping it fast.

Compared to common manual machines, it comes with many more functions. Among them, the most useful one is that it can correctly sort the caps and pick out which is best for the machine.

The Bottom Line

The bottle capping machine is a multifunctional equipment. The bottle capping machine is a multifunctional equipment. So, knowing its important components can be beneficial in boosting your packaging business!

After reading this article, if you would like more information about bottle capping machine parts, you can refer to the capping machine manufacturer's manual or contact Ipharmachine, our experts are available 24/7 to help you.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche