Capsule Polishing Machine YJP-III: Cleaning

Capsule Polishing Machine needs regular cleaning to maintain its status.

Use the gauze to clean the machine base and the transmission parts inside the machine with clear water or alcohol. Also clean the hopper, inlet, motor cover, top cabinet and lower slot with the same method.

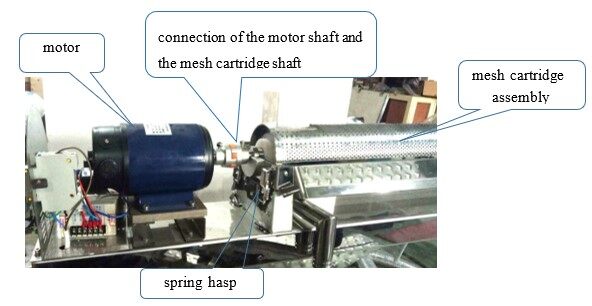

Use a Phillips screwdriver to loosen the screws on the both sides of the lower part of the motor cover (total of 8 screws), and remove the motor cover.

Loosen the spindle hasp of the spindle assembly, take out the hopper, and open the top cabinet.

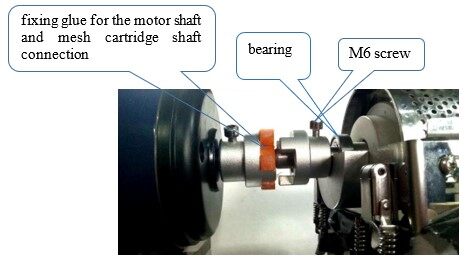

Loosen the two M6 screws of the connection of the motor shaft and the mesh cartridge shaft.

Loosen the two M6 screws, remove the mesh cartridge, and take out the spiral brush and clean it with water or gauze. The brush and the mesh cartridge can be dried with compressed air.

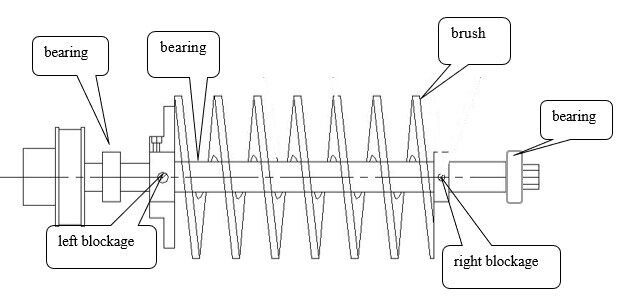

- Wipe the two bearings on the main shaft with a dry cloth and apply them anti-rust oil;

- Remove the left and right blockage, and clean the blockages and the mesh cartridge with water or alcohol.

Notice: the spacing of the spring steel wires inside the mesh cartridge shall be even, and the width of the lane between the steel wire and the inlet or outlet shall longer than the length of the capsule.

After all the components being cleaned and dried, assemble the machine in reverse order of disassembly for usage.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche