Coating Machine BYC-300: Basic Operation of Converter

Basic Operation of Converter

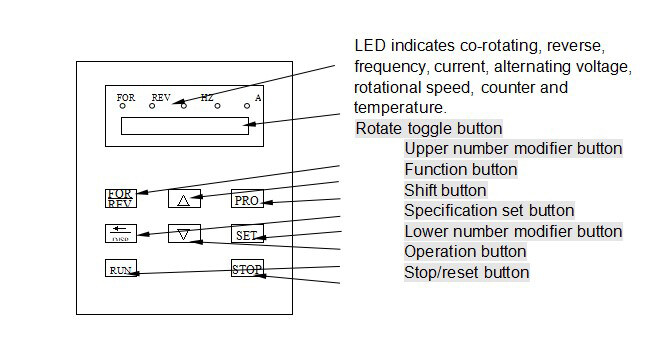

HLP-A Series

Simple operation: Connect power, open urgent stop button and the figure shows “000.00”. When the motor is operating, the figure indicates the operation frequency. Press “▽” button or “△” to change operation frequency. The last figure “0” of present figure “050.00” signs and press shift button to “5”. Then, press “▽” button to change figure from “5” to “2” and finally press “SET” button. The operation frequency is 20Hz now.

The specifications of converter have been set before leaving the factory and you don’t have to change it. If you want to change other specifications, please refer to converter user manual.

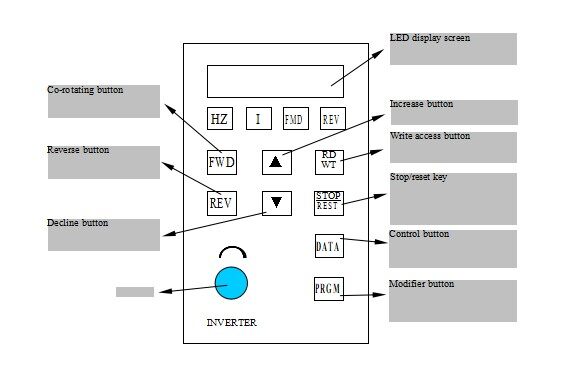

SAJ8000-M series

1) Functions of indicator lights

- HZ:LED displays frequency data.

- I:LED displays electric current data.

- FWD:The inverter is co-rotating work.

- REV:The inverter is work reversely.

2) Monitor operation specification

When the converter is operating, press “DATA” button, “▲” button or “▼” button to observe current or running frequency.

3) Simple operation

Observe specification: set “F039” to 0, “F040” to 25.00. Under this condition, potentiometer works.

Start/ stop: Press “FWD” button to co-rotating, press “REV” to work reversely and press “STOP/RESET” button to stop converter. Rotate potentiometer can change rotational speed.

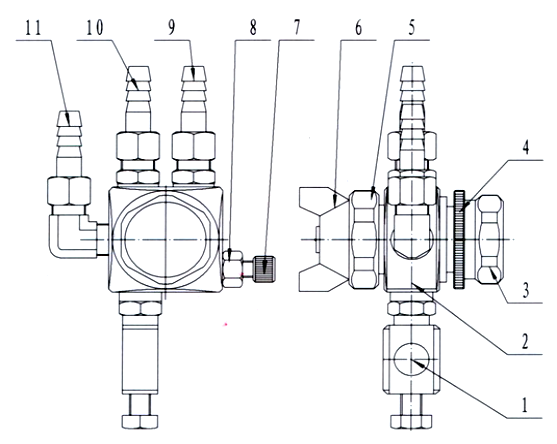

Construction and Usage of Spray Gun

- Fixing base

- Spray gun body

- Flow adjusting button

- Knob jam nut

- Spray head jam nut

- Cone angle adjusting spray gun head

- Atomization adjusting button

- Jam nut

- Liquid blasting inlet

- Coating liquid inlet

- Shoot fire inlet

- How to use the spray gun

- Flow control: Loose (4) knob jam nut at clockwise and adjust (3) flow adjustment button at counterclockwise to increase flow. After adjusting, lock (4) knob jam nut.

- Atomization adjustment: the same as flow control.

- Atomization cone angle adjustment: Loose (5) spray jam nut, rotate (6) spray gun and adjust to the proper atomization cone angle and finally lock (5) spray head jam nut.

Notice

Use distilled water or ethanol to clean spray gun, liquid barrel and pipe.

If coating liquid isn’t sprayed, please check: A. The liquid switch of the electric control cabinet; B. Whether the compressed air is purified (it is better to install cleaner in the air pump outlet); C. Whether the coating liquid is mixed evenly; D. Whether the spray gun is locked when adjusting atomization cone angle.

If crevasse occurs, please disassemble the following accessories: flow adjustment button→ spring→ tag pin→ spray head jam nut→ cone angle adjusting spray gun head. Use fine needle to clean spray head hole or use compressed air to blow-back.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche