A Complete Guide to Tablet Press Tooling System

In our previous blogs, we’ve already know the parts of tablet press machines and their function in the three steps of tablet compressing procedure. However, there is a system beneath all these components which directly influences the compression stage——the tablet press tooling system.

In the following parts, we’ll unveil the definition of this system as well as its function.

An introduction to tablet press tooling system

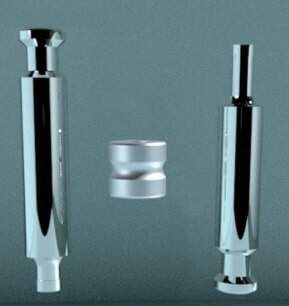

Narrowly speaking, tablet pressing tooling system basically contains the punches and the dies of the tablet press. They decide the features of the tablets.

What is a tablet press tooling?

Like what’s introduced above, the punches and dies play a decisive role in tablet making. Not only are they essential components of tablet press machines, but they are also called tablet press tooling as well.

The punches can be divided into upper punches and lower punches. Together they compress the powder into tablets. In single punch tablet presses, only upper punches give force to the powder. In rotary tablet machines, both upper and lower punches work as sets in finishing the compression step.

The punches in rotary tablet machines are fixed to a turret. When the turret spins, it carries the punch sets moving through several cams. The lower punches mainly help hold the powder inside the die cavities. They also eject the fully compressed tablets from the die cavities after the compression stage.

The upper punches compress the powder to squeeze out the air inside first. Later, they compress the powder into pills precisely.

The die cavities and punches sets decide the shape and size of the tablets. Since these features are vital in tablet manufacture, the punches focus a lot on accuracy. Also, they must be durable in long terms of usage.

That’s where our company, IpharMachine, can help judging by our 17 years of efforts in this field.

Types of tablet punches & dies

There are multiple types of tablet punches and dies in tablet press toolings.

The simplest type of tablet press tooling can make tablets in regular shapes——round, oval, etc.

If needed, they can also provide some tablets with symbols attached. Figures, letters are the most common ones, together with the division line.

A normal tablet press tooling provides round tablets. However, the low cost also brings some problems, among which the counterfeit is the worst.

So here comes the solution——the customized tablet press tooling.

No matter what features you want on your tablets, customized tablet press tooling can help. You can ask the tablet compression machine companies to provide special shapes or labels on the punch heads to get yourselves unique-designed tablets. These tablets surely help to prevent the appearance of counterfeit tablets.

You may also want your machine to be more efficient in bulk production. That would ask the machine factories to build larger turrets or inputs more punch sets into a single turret. Smaller punches are also needed in some cases to make unusual tablets.

These customized tablet press toolings helps to deal with some special requests of tablet manufacturers. The disadvantage might be their higher price comparing with the normal ones. They are welcomed by large companies in pharmaceutical industry. Small companies or start-ups favor normal tablet press toolings more, for they can lower the cost in purchasing machines.

Suitable material for punch & die systems of tablet press

The material for punch and die systems of tablet press should meet the standards in tablet manufacture (CGMP). The raw material used for making tablets also matters. The material for the system is not allowed to pollute the tablets.

Besides, the longevity of the system requires the punch heads and dies to be more abrasion-resistant. Some raw materials don’t ask for this feature.

Stainless steel, with its strong wear resistance, is usually used to make dies. The stainless steel helps to keep the stability of the dies. Its compression resistance also keeps the dies from being out of shape during continuously compressing.

The dies made by stainless steel won’t wear for a long period of time, preventing the mass production from a series of problems. The tablets remain the same features, and won’t cost more power to force them out of the die cavity.

When erosion may happen between the powder and tablet press tooling systems, we need to use other materials to build the punch heads and dies. Coating the punches with other materials is another choice, which we would discuss in the following paragraphes.

Treating & coating tablet press tooling

Sticking and picking are problems you might find in tablet producing. When the granules of the raw material stick into the symbols (letters, figures, etc.) by the punches, this phenomenon is called picking. The punch heads stick the tablets after the compression is sticking.

To reduce the appearance of these problems, often there are treatments to the tablet press tooling. The polishing to the punch heads is a normal treatment, but an effective one to stop the sticking and picking.

However, this only delays the tablet press tooling systems’ aging. Thus, coating the heads of the punches becomes a normal way to enhance the durability.

Effervescent tablet production prefers diamond as the coating in the tooling system. The powder is not sticky, so as the diamond layers. The layer is wear resistant, and it’s the hardest material on the earth.

As most manufacturers’ favorite, galvanic chrome treatment is widely used in most normal tablet compression machines. This treatment lengthens the longevity of the tooling system, and the cost won’t be too high.

The component of coating can be a variety of metals or metal compounds, such as aluminum, nitride and titanium nitride. They all provide a higher surface hardness for the punch heads and dies.

Conclusion

The tablet press tooling system is the most essential part in a tablet compression machine. Choosing a proper tooling is of great importance in manufacturing tablets. iPharMachine, with years of experience in pharmaceutical industry, welcomes people from all over the world to get the best machines as well as expert services.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche