Continuous Band Sealer LF1080: Adjustment

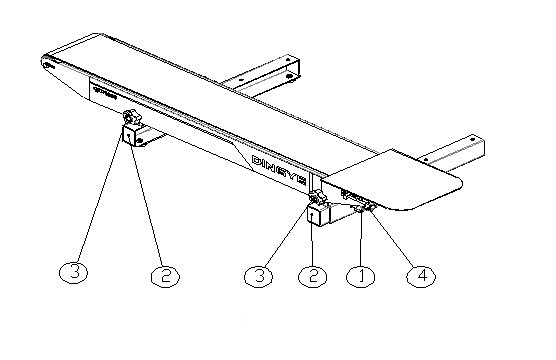

Conveyor adjustment

- Adjusting lock knob

- Foot stool

- Lock knob

- Conveyor tensioning adjusting knob

Continuous Band Sealer Conveyor tensioning adjustment: When conveyor is too tighten or loosen, spin the “conveyor tensioning adjusting knob” to the tension is suitable.

Conveyor table adjustment (front and back): when the work table need adjust, loose the “adjusting lock knob”,then pull or push work table, when it is suitable, tight the “adjusting lock knob”.

Conveyor table adjustment (up and down): when the work table need adjust, loose the “lock knob”, then pull the work table up or down,when it is suitable, tight the“lock knob”.

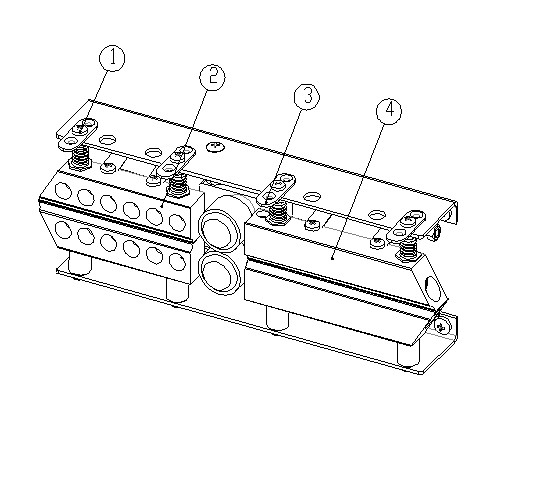

sealing parts adjustment

- Adjusting screw

- Cooling block

- Elevate slice

- Heating block

Heating and cooling block spacing adjustment(up and down):Because sealing material and thickness is different, so the space of heating and cooling block need adjust when sealing different product.Specific methods:rotate “adjusting screw”deasil can increase the space of up and down.rotate “adjusting screw”widdershins can decrease the space.

Replace sealing belt and adjustment:when the heating block cool,pull the elevate slice up and rotate it 90°;And loose the spring between pattern printing wheel and pressure wheel,take down the gear belt,then push the processed driven wheel,take down the sealing belt,replace new sealing belt,then adjust all back.

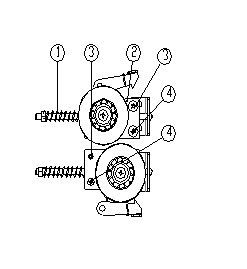

Driven wheel with holder adjustment

- Spring

- Hold for driven wheel

- Adjust screw

- Ajust screw

If sealing belt is skewing,please adjust the adjust screw to make it properly.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche