Difference Between Alu-Alu Packaging and Alu-PVC Packaging

When it comes to pharmaceutical packaging, blister packaging is one of the most popular solutions. This packaging option mainly comes in two styles, varying based on the materials used. Actually, blister packaging that people talk about in the pharmaceutical industry often refers to the aluminum-plastic (Alu-PVC) option. The other type uses aluminum-aluminum (Alu-Alu) for packing medications.

If you've ever wondered about the difference between Alu-Alu and blister packaging, here's a simplified breakdown. Whether you're a curious consumer or an industry insider, this blog post will leave you enlightened and ready to make informed packaging choices. Let's jump right in to unravel the mysteries behind Alu-Alu and Alu-PVC blister packaging!

What is Alu-Alu Packaging?

The term "Alu-Alu" is derived from the materials used in this packaging style. Alu-Alu packaging comes in a multiple-layered structure. Simply put, it uses aluminum-based materials for both the lidding and base of the blister pack.

The aluminum foil layers in this packaging form play a vital role in protecting the content inside the blister cavity. They serve as a shield against moisture, air, and UV rays. This enhances shelf life and tamper resistance, making it ideal for packing sensitive medications.

What is Alu-PVC Packaging?

Alu-PVC packaging is another widely used blister packaging in the pharmaceutical industry. It's a combination of two materials. This packaging utilizes a clear PVC film as its base. It is coated with a layer of aluminum foil to create the blister pack.

The PVC film is the primary structural component of this pharmaceutical packaging. It offers a robust and flexible base for securely holding the medication. The aluminum foil layer is sealed to the PVC film, providing a protective barrier to prevent moisture, oxygen, and light from drug degradation.

How to Make Alu-Alu Packaging?

Typically, the Alu-Alu blister packs are produced by the following steps.

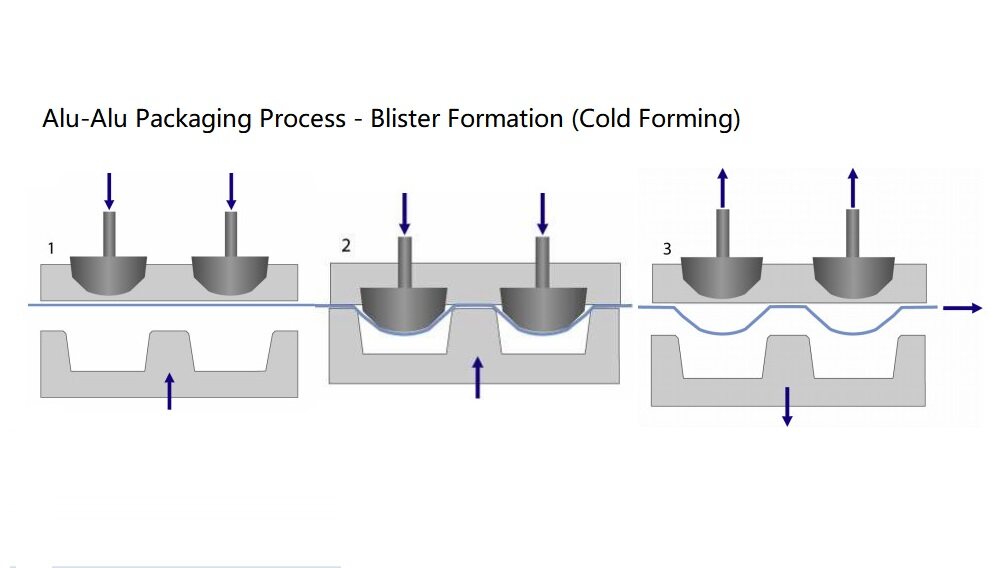

1. Blister Formation. Due to the characteristics of the materials, Alu-Alu packaging is made by cold forming. The aluminum foil is sandwiched between layers of plastic film during the process. The laminate is pressed into a mold cavity using a stamp without applying heat.

2. Product Filling. The formed blister pack is then transferred to the filling station, where the cavities are filled with the required products.

3. Sealing. After filling, another layer of aluminum foil is applied on top of the filled blister cavities by sealing.

4. Perforation and Cutting. The sealed blisters are then perforated if necessary and cut into individual packs.

How to Make Blister Packaging?

The Alu-PVC packaging process is quite similar to the Alu-Alu process. The major difference lies in the blister forming step.

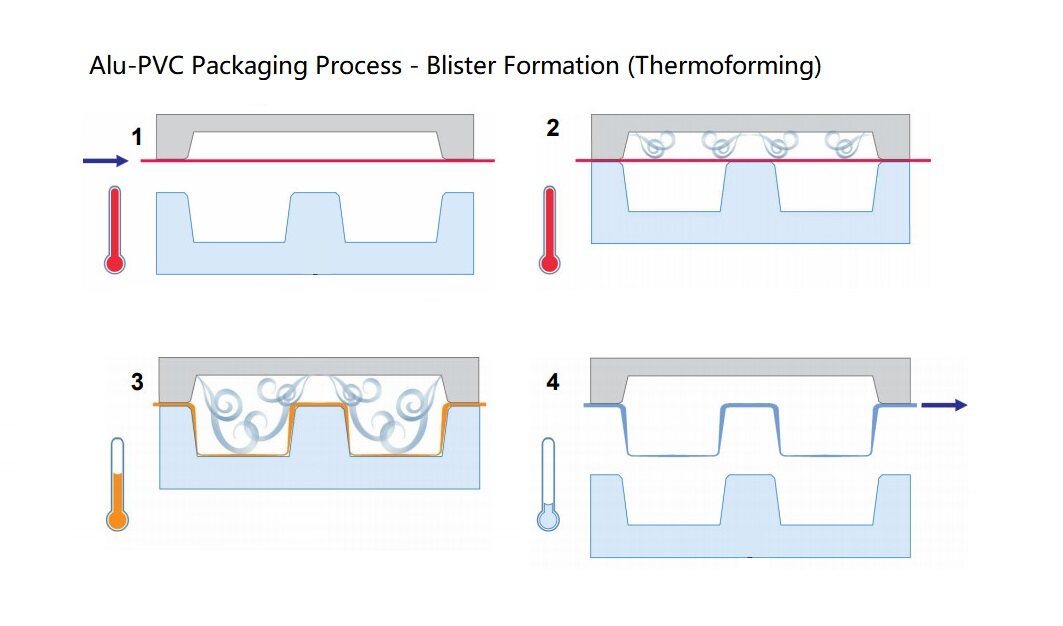

1. Blister Formation. Alu-PVC packaging utilizes thermoforming. The plastic film is heated to a specific temperature to be soft and pliable. It is then placed on a mold and subjected to vacuum or pressure to shape the blister cavity.

2. Product Filling. After being formed, the blister pack is taken to the filling station, where the products are placed into each cavity.

3. Sealing. A layer of aluminum foil is heat-sealed to the preformed PVC blister pack. All cavities are securely covered and sealed.

4. Perforation and cutting. This step is the same as the one during the Alu-Alu packaging process.

Pros and Cons of Alu-Alu Packaging Vs. Blister Packaging

The difference between Alu-Alu and blister packaging also manifests in their own benefits and drawbacks.

Advantages of Alu-Alu Packaging

1. In Alu-Alu packaging, aluminum foil offers exceptional protection for the medication from humidity, oxygen, and UV radiation. These external elements could degrade its quality or efficacy.

2. The robust design of the Alu-Alu blister pack safeguards against physical damage or impact during handling, transportation, and storage.

3. The superior barrier properties of Alu-Alu packaging contribute to an extended shelf life for pharmaceutical products.

4. Alu-Alu packaging features tamper resistance. For example, blister perforation or tear-off tabs can provide visible indications of tampering. This ensures the integrity of the products inside.

Disadvantages of Alu-Alu Packaging

1. Alu-Alu packaging is generally more expensive than other packaging solutions due to aluminum-based materials. It can lead to increased production costs.

2. Though the aluminum foil itself is recyclable, the blisters in Alu-Alu packaging are not made from this single material. Also, aluminum foil is not biodegradable, so it has environmental implications to some extent.

3. The aluminum-based materials used in the packaging make it difficult to visually inspect the contents of each blister cavity without opening the package.

4. Aluminum foil is not that flexible compared to plastic material. It can't be simply molded into any shape.

Advantages of Blister Packaging

1. Alu-PVC blister packs are made of plastic-based materials. This results in lower production costs, making it a more cost-effective option for pharmaceutical packaging.

2. Alu-PVC packaging allows for easy visibility of medications inside the blister cavities. This enables end consumers to check the product integrity and verify the dosage before consumption.

3. Alu-PVC blister packaging is more flexible and versatile in customization. The PVC blister cavities can be easily molded to accommodate different product shapes and sizes.

Disadvantages of Blister Packaging

1. While Alu-PVC packaging provides reasonable protection, it may not offer the same barrier performance level as Alu-Alu packaging.

2. The plastic material makes Alu-PVC blister cavities more susceptible to impact damage during handling, transportation, or storage.

3. PVC material has poor thermal stability. It's crucial to carefully control the temperature during the blister formation and heat sealing stages.

4. The transparency of the PVC material is a two-edged sword. While it allows for excellent product visibility, it may not be suitable for light-sensitive medications.

5. PVC is not readily biodegradable. Improper disposal of PVC blister packs can cause environmental concerns.

A Tablet Summary of the Difference Between Alu-Alu and Blister Packaging

Here's a summary of comparing Alu-Alu Packaging Vs. Blister Packaging. This comparison table will show you a quick overview of the difference between Alu-Alu and blister packaging.

|

Alu-Alu Packaging |

Alu-PVC Packaging |

|

|

Composition |

Aluminum foil layer sandwiched between plastic film layers |

Aluminum foil layer with a layer of polyvinyl chloride (PVC) |

|

Barrier Properties |

Exceptional shield against humidity, oxygen, and UV rays |

Good barrier against moisture and light |

|

Visibility |

No visibility for the contents inside the blister cavities |

Transparent PVC film for excellent product visibility |

|

Tamper Resistance |

Enhanced tamper resistance with features like blister perforations or tear lines |

Can be made tamper-resistant with appropriate blister designs |

|

Flexibility |

Less flexible, suitable for standard-sized blisters |

More flexible, suitable for various blister shapes and sizes |

|

Cost |

Generally more expensive |

Generally more economical |

|

Heat Resistance |

Aluminum-based materials with good resistance to temperature changes |

Plastic-based materials with limited heat resistance |

|

Recyclability |

Less recyclable due to a combination of materials |

More recyclable with separate PVC and aluminum recycling |

|

Shelf Life |

Extended shelf life due to excellent barrier properties |

Good protection but slightly inferior barrier properties |

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche