High-speed Bottle Unscrambler PBL-160 Maintenance

Maintenance

Daily Maintenance

Daily Check before start

Before start the machine, must check no sundries, like: spanner, screw and so on.

Check the power supply, air supply is normal. The electric wire, or air pipe is no broken.

Daily Check before the worker‘s off

The worker must check the power supply and air supply disconnect before be off. Besides power and air supply check, still need to check below works:

Clean the whole machine appearance, use the dry soft cloth to wipe with the appearance. Or use the compressed air to blow the dust.

When wipe with, please check if has the unscrewed nut, if has, please screw it tightly.

Must wipe with the unscramble disc and other parts which touches with the bottles by dry soft cloth with the alcohol.

Routine Maintenance

Every month need to add the 3# white grease on the gear.

If this machine do not run for one month, must to apply the anti-rust oil on the Bottle Unscrambler.

Common Faults and Elimination Methods

| FAULT | REASON | ELIMINATION METHODS |

| The month-downward bottle not be rejected | The bottle-blow air supply is not enough |

Adjust the air supply

|

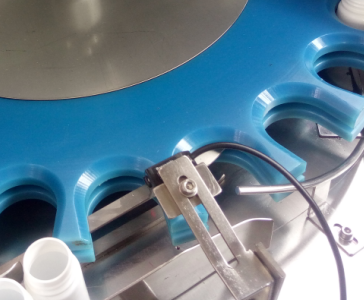

| The bottle is choked when unscramble | Not adjust the unscramble disc well | Adjust the unscramble disc height and the width of the exit of bottle unscrambler. |

| The unscramble disc can’t work |

1.The motor or transmission gear is damaged 2.Friction plate can’t work 3.power is not connected |

1. Replace or maintain the motor or transmission gear. 2. Replace the friction plate or adjust the friction force between the friction plate and the big gear. 3.connect the power supply. |

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche