How To Fill Gelatin Capsules With Liquid?

Hard-shell capsules are probably the first choice when we want to fill powders, granules, pellets, micro-tablets, or combinations. And when you need to make a drug or supplement in liquid form, filling softgels might be the first popping into your head. That said, sometimes hard-shell gelatin capsules work better for liquid filling than softgels.

Liquid-filled hard capsules (LFHCs) refer to hard-shell capsules containing liquid-based formulations. The liquid hard capsule filling is actually not new technology. It emerged in the early 1980s as an alternative to softgel technology.

Have you ever wondered how to fill gelatin capsules with liquid? The process of making liquid capsules is quite straightforward. It's kind of similar to that of solid formulation encapsulation. Liquid-filled capsules are also produced using specifically designed equipment - a liquid capsule filling machine.

1. A brief intro to the liquid capsule filling machine

As with conventional capsule fillers, liquid capsule filling machines are available in three types - manual, semi-automatic, and automatic. In this article, we're going to focus on the automatic type.

The liquid capsule filling machine consists of several major parts. Most of them serve a similar function to the parts of conventional automatic encapsulation machines.

Yet, the liquid capsule filling machine alone is not enough to complete the manufacturing process. In other words, you need to enable the machine to work in synergy with other systems.

The most important parts of a liquid capsule filling machine may include the following:

- Capsule hopper

- Capsule feeding unit

- Liquid hopper

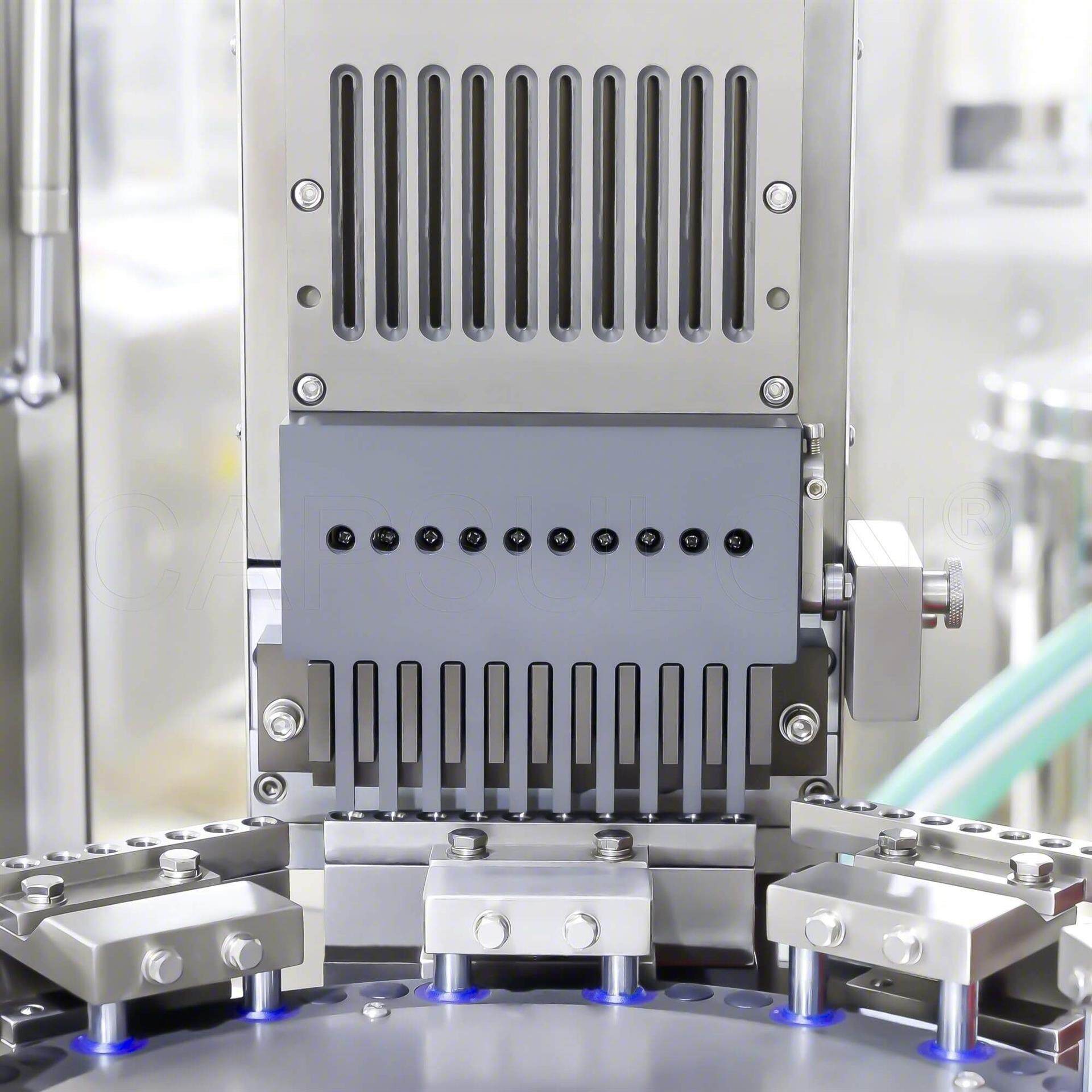

- Liquid dosing and filling system

- Ejection system

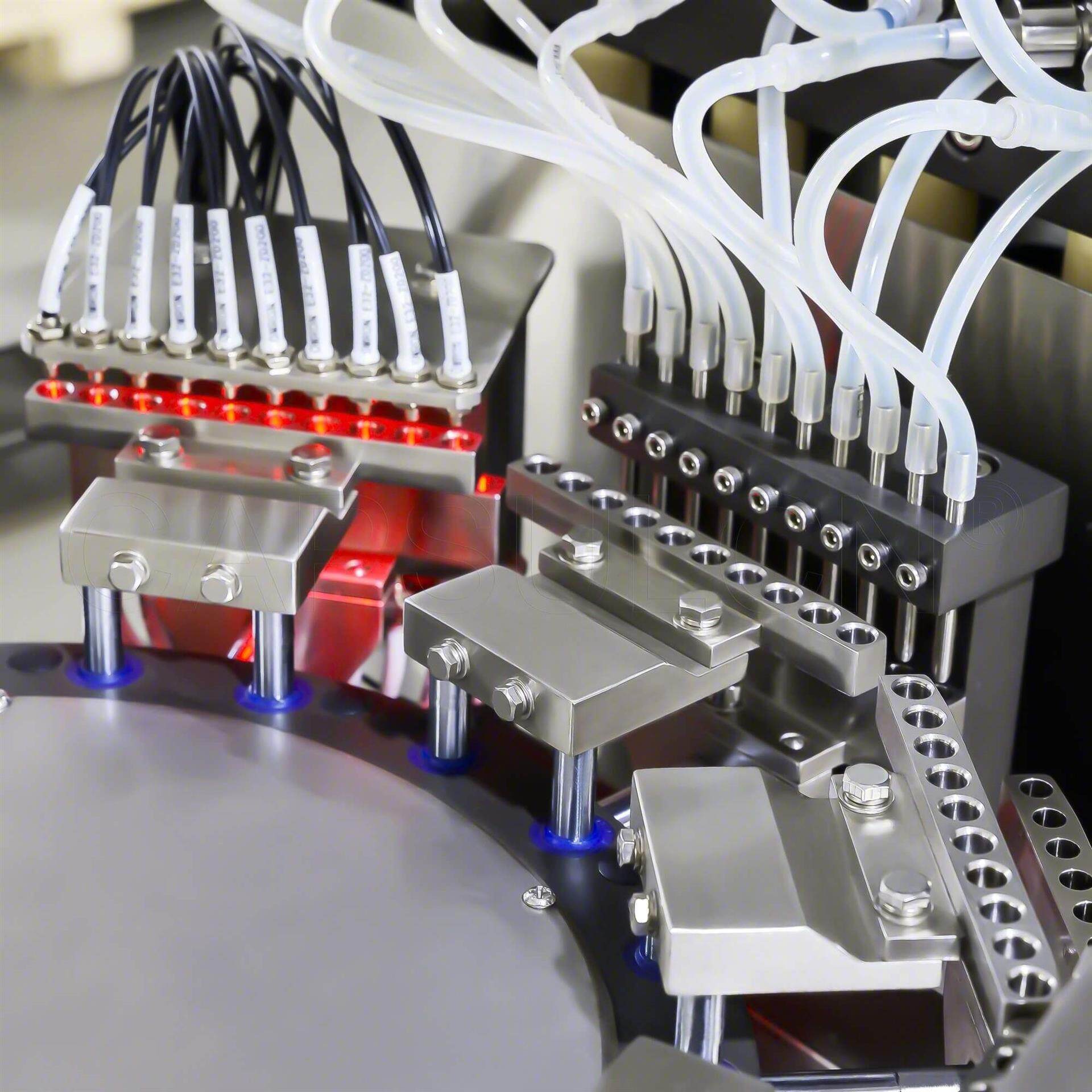

- Vacuum system

- PLC with HMI touchscreen

- Transfer system

- Sealing system

- Drying system

The sizes and outputs of encapsulation machines vary. It's crucial to pick a model that meets your production needs. In the meantime, it should comply with necessary quality standards, such as GMP, or cGMP, as set forth by the FDA.

2. So, how to fill gelatin capsules with liquid?

If you have read this far, you probably have a rough idea of the liquid capsule filling machine. Now, let's dive into the manufacturing process.

To help you learn how to fill gelatin capsules with liquid in a more intuitive way, let's take a specific machine as an example.

At iPharMachine, we offer an array of best liquid capsule filling machines. CapCN-L30 is a state-of-the-art model with the utmost versatility and flexibility.

3. Liquid capsule manufacturing process

How to fill gelatin capsules with liquid using a machine? There are a series of stages as follows:

Stage 1: Preparation of empty capsules and liquid fills

The operator loads empty capsules and liquid fills into their hoppers. CapCN-L30 is capable of handling capsule sizes ranging from #00 to #5. Aside from liquids, the equipment can also fill many other materials, such as semi-solids, suspensions, pastes, and waxy substances.

Stage 2: Capsule feeding and separation

During this stage, the empty capsules are rectified and transferred to the segments in the vertical position. When each capsule is fed into the segment pore, they are ready for the next step - separation.

The vacuum system plays a key role in capsule separation. When the capsules are separated, the bodies fall into the bores of the lower segment, while the caps remain in the bores of the upper segment.

Stage 3: Liquid dosing and filling

After separation, the lower segment holding empty capsule bodies moves to the filling station. Liquid fills are pumped into the filling station by a peristaltic pump. The pump enables precise liquid dosing without leaking, dripping or air bubbles.

Stage 4: Capsule closing

Now the lower segment carrying filled capsule bodies rotates to the closing station. As with conventional capsule filling machines, the upper segment is lined up with the lower one. A row of pins pushes the bodies up from the bottom of the lower segment to close the capsules.

Stage 5: Filled capsule transfer

In the above four steps, any capsule that fails to separate or close is rejected by vacuum. In this stage, the closed capsules are pushed out of the segments into the holes of a rotary disc. All segments are then cleaned by vacuum and go back to the first place for the next circle.

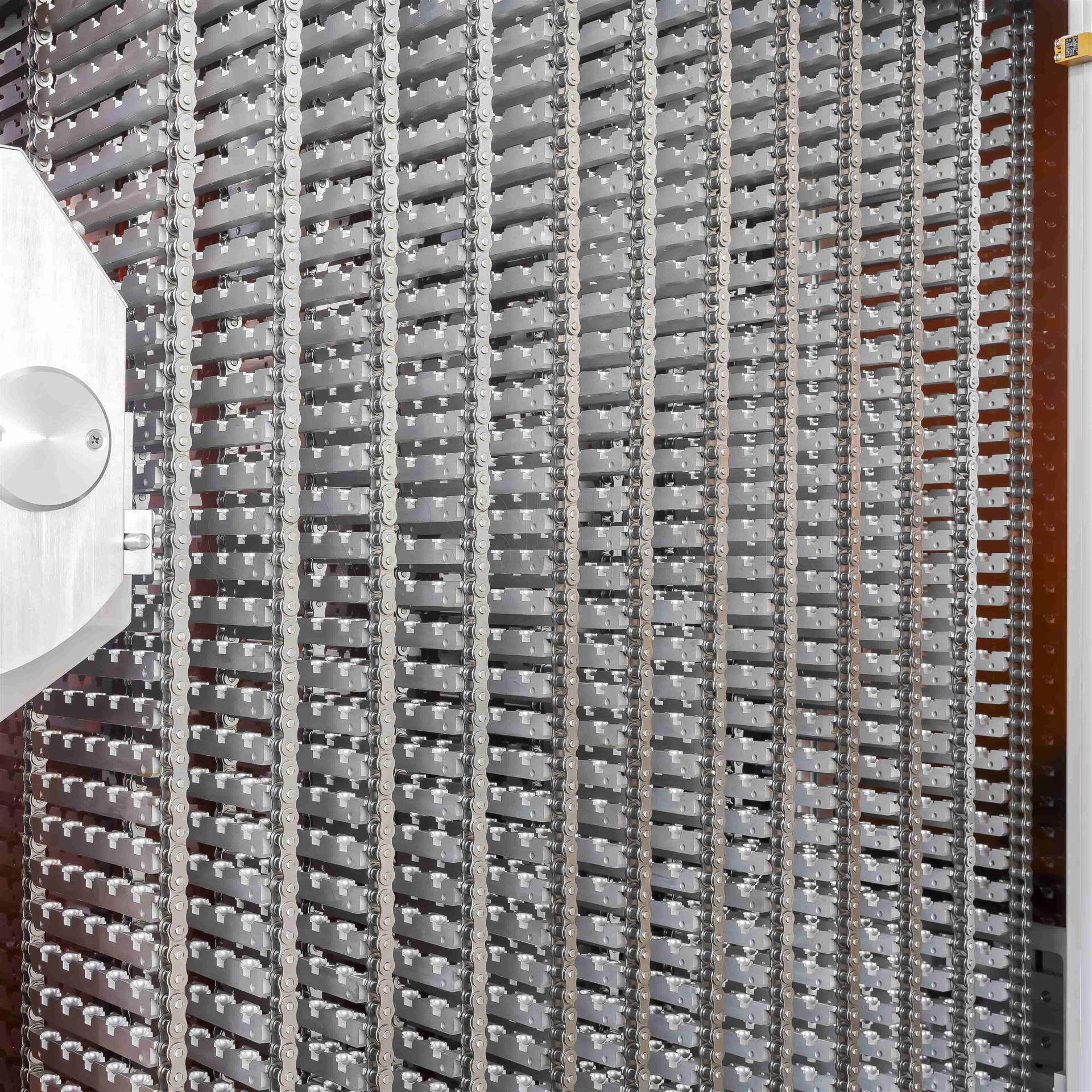

Since CapCN-L30 is not a standalone machine, it's connected to a transfer system that takes the filled capsules to the sealing and drying stations. The transfer system consists of a rotary disc, a guide chute, a transfer roll, and a slat conveyor.

When the disc rotates to align with the guide chute, a line of pins pushes the capsules out of the disc holes into the channels of the guide chute. And then, these capsules go down along the channels to reach the transfer roll.

The transfer roll is designed with cavities, allowing the capsules to sit. The liquid-filled capsules are then oriented and transferred to the pockets of the slat conveyor via the roll.

Stage 6: Filled capsule sealing

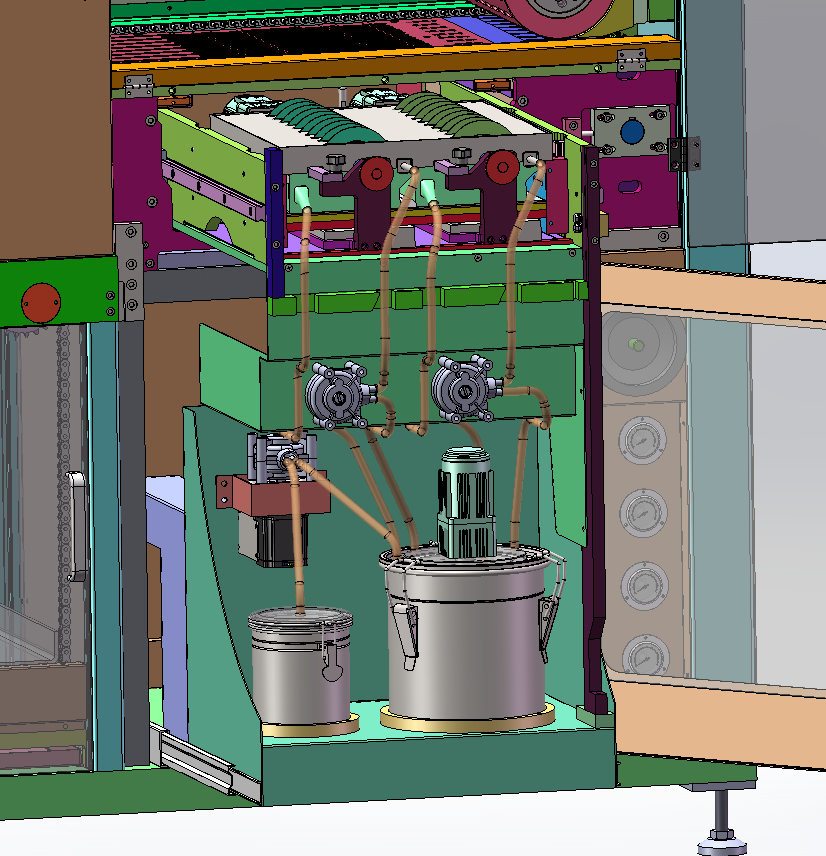

The sealing mechanism is mounted under the slat conveyor. It comprises two sealing rollers, two gelatin bowls, a water tank, and a gelatin tank. By the way, two gelatin bowls and the gelatin tank are equipped with heaters to maintain the temperature of the gelatin.

When the filled capsules pass through the sealing station via the slat conveyor, the sealing rollers apply the heated gelatin and rotate around the joint of the capsule to create a sealing band. Why are there two sealing rollers? It's for improving the sealing effect.

Stage 7: Sealed capsule drying

The sealed capsules are then moved to the drying carriers from the slat conveyor and transferred into the drying box. The drying box uses filtered indoor air at a constant room temperature to dry the capsules on the carriers.

Finally, the finished products flow out of the machine through the discharge chute. The liquid capsule manufacturing process is complete.

4. Wrap-Up

Liquid-filled hard capsules come with a lot of benefits. Research shows that a liquid hard-shell capsule can enhance the bioavailability of poorly water-soluble drugs. And the banded capsules are tamper-evident to help preserve the quality of the formulation inside.

If you're going to add liquid capsule manufacturing into your business but feel confused about how to fill gelatin capsules with liquid, we hope you find the answers to all your questions in this article.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche