How to make up a suitable bottling line

We have mentioned that it is better to choose a bottling line according to the products. And in order to make up a bottling line, machines should be of high degree of automation, stable and reliable performance, convenient operation and maintenance, exquisite appearance and easy transportation, qualification rate of counted particles.

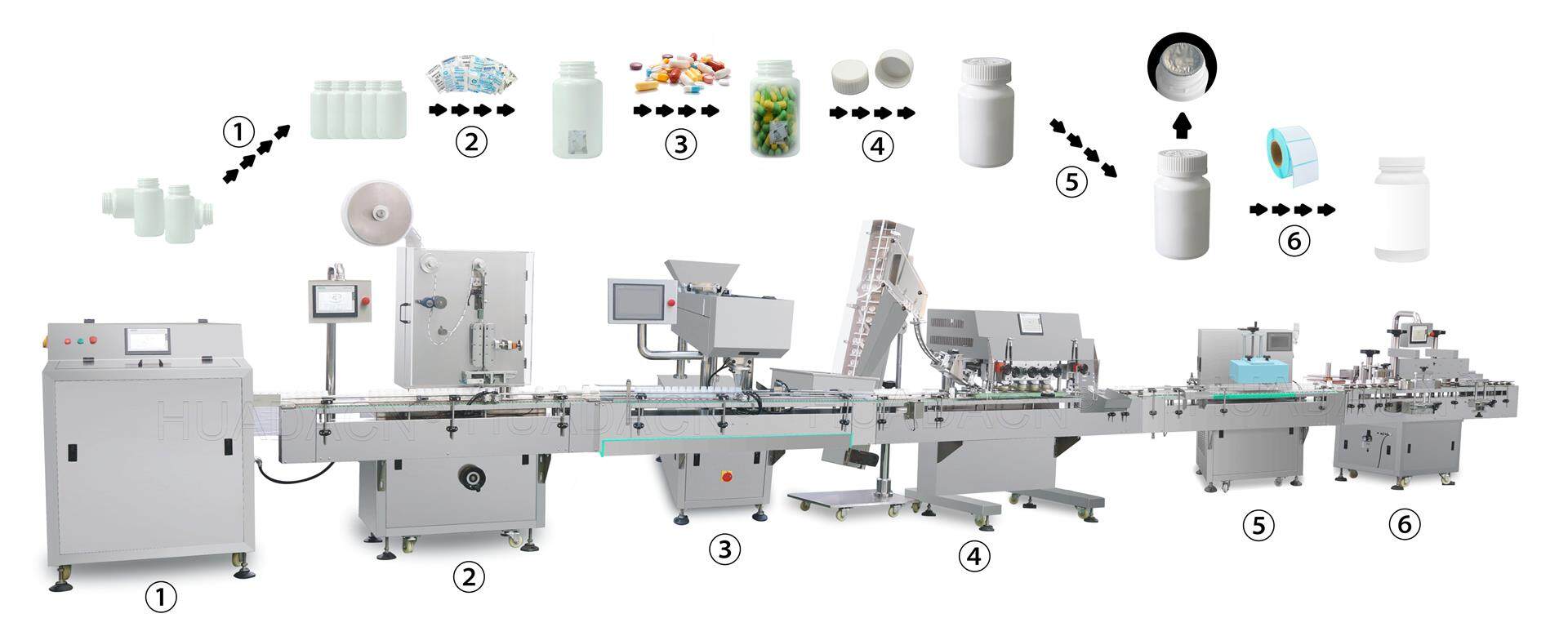

The components of the bottling line: bottle setting - bottle cleaning – counting – inserting – capping – sealing - labeling.

Here, we will briefly introduce the functions and features of each main station of the bottling line and hope it will be helpful to who are going to picking up a bottling line.

Bottle unscrambler

The machine for first station of the bottling line is bottle unscrambler which is mainly for arranges the messy plastic bottles and transfer them into the conveyer. According to the operation speed, it can be divided into low-speed bottle unscrambler and high-speed bottle unscrambler. The speed of the low-speed bottle unscrambler is about 60~100 bottles/min. The structure is relatively simple, the price is low and the machine performance stability. Except for the speed, the machine could meet most requirements, and it is suitable for round and square bottles. For high-speed bottle unscramblers, the speed is 100 ~ 250 bottles/min. The structure is complex and meets the needs of high-speed operation. It can be used for shaped bottles such as flat bottles and oval bottles.

Counting machine

The counting machine is more complicated, you may find detailed information in “Overview of the development of counting machine” above.

Inserter

According to the material need to be inserted, the inserter can be divided into cotton inserter, paper inserter, etc. These inserters can be kept or removed based on the detailed requirements of the bottling line. The new type of inserter generally adopts an electronic positioning system to set the amount for inserting. The high-quality machine should be flexible in starting, fast, low in noise and reliable in positioning. Another important point is the depth of the inserting. If the material cannot be well inserted, it will affect the subsequent process of capping and sealing.

Capping machine

The capping machine is divided into claw capping machine and screw capping machine. The claw type capping machine is relatively slow in speed, and different manipulator need to be replaced when cap specification changes, and the price is relatively low. The screw type capping machine is faster, and only needs to adjust the parameters when cap specification changes, but the price is relatively high.

Sealer

The sealer is used to heat and seal the aluminum foil of the bottle cap, and has a high-power magnetic field and radiation, which has certain influence on other equipment and personnel. The high-quality sealer should be of high shielding, good cooling and high speed. It can also be seal bottles when there is some foreign matter, and automatically remove the bottle without aluminum foil.

Labeler

The labeler is used to attach the labels to the bottle body, for identifying products and manufacturer. The label is composed of self-adhesive or paste materials, and now the self-adhesive is popular in users. Self-adhesive labeler can be divided into circumferential labeling, side labeling, double-sided labeling, etc, and some machines are suitable for all different forms of labeling. The main factor for picking up a labeler include speed, stability, and anti-interference ability. In addition, there are many labels that can directly print simple information such as date and lot number. Some labelers can alarm for some situation as labels broking, no labels, codes missing, and labels missing.

In addition to the above machines, a cartoning line could be connected after the bottling line, putting in the instructions in, and packing bottles into the boxes. For sure, the user shall make the packing line according to their needs. For example, how many different of material need to be packed, and what processes of packing are required for each material, and then chose the products of most cost-effective and best service, based on their financial ability.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche