7 Most Important Liquid Filling Machine Parts You Need To Know

Liquid filling machines come in a variety of types. However, as the demand for machine automation and accuracy increases, automatic liquid filling machines are becoming more widely used compared with the other types.

Whether you are a beginner or an expert, understanding the main parts of an automatic liquid filling machine will spare you a lot of trouble. This can help you make wise decisions from purchasing your first liquid filler to maintaining the machine.

Well, before buying a liquid filling machine, we need to do our research first. Knowing the working principle of liquid filling machine and its parts is essential to your final decision. In this blog, we will guide you to figure out the liquid filling machine parts. Let's get into the topic!

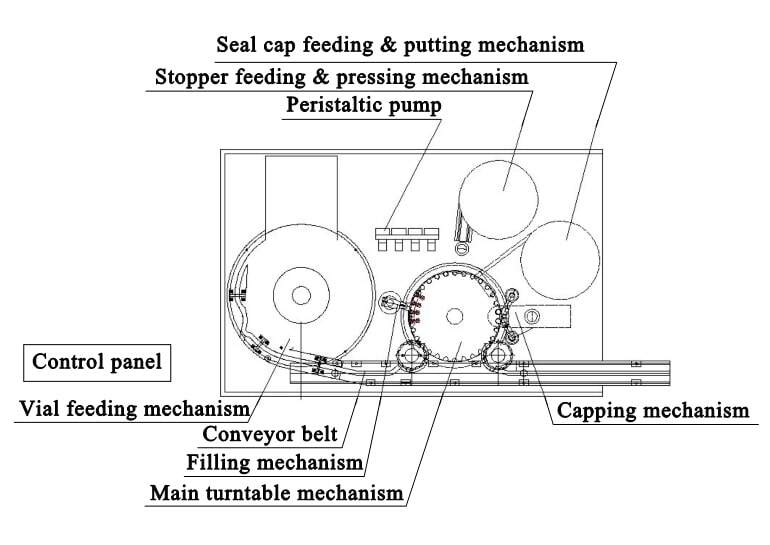

Automatic Liquid Filling Machine Diagram

Before jumping right into how each part of an automatic liquid filler works, we first take a look at the entire machine. With so many different types of liquid filling machines, here is a diagram of an automatic liquid filler. On the diagram, we can see clearly the main components of a filling machine and how they are arranged. Of all the parts, the filling mechanism plays a decisive role in the success of filling process, and we will explore it later on.

What Are The Important Parts Of A Liquid Filling Machine?

An automatic liquid filling machine is a versatile device that consists of many individual parts. Below is a guide that explains the functions of important machine parts in detail.

1. Bottle Feeding Mechanism

The bottle feeding mechanism is the very first stage in the filling process. The bottles are manually put into the inlet of the feeding mechanism. Then, the turntable rotates under the drive of motor, enabling the bottles to enter the conveyor belt in a orderly and automatic manner. Depending on filling head number, there are different types of bottle feeders to choose from.

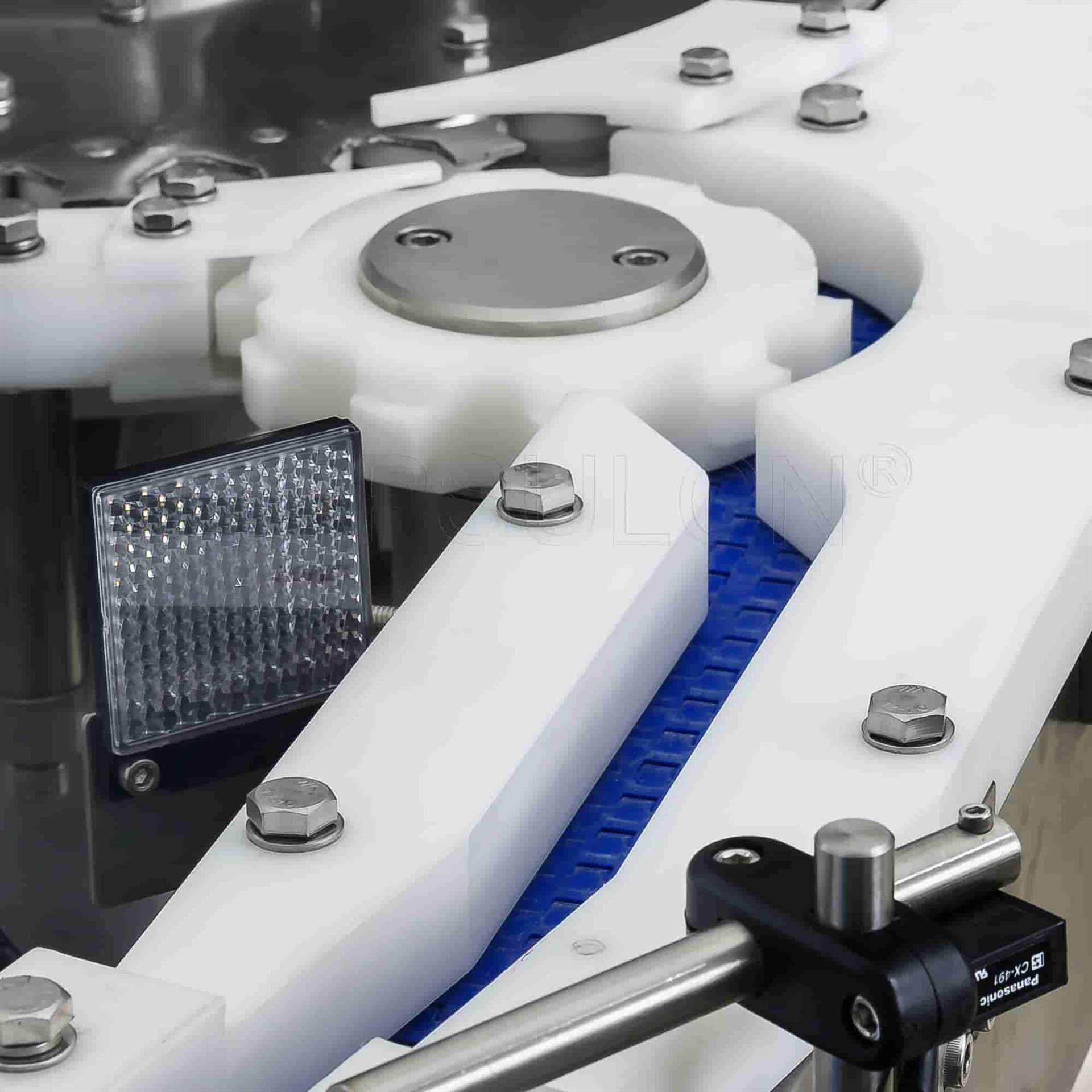

2. Conveyor Belt

Chances are you've seen a conveyor belt on your liquid filling machine. However, few people are aware how important it is. Conveyor belts are used to carrying containers throughout the entire filling line.

In addition, the speed and size of a conveyor belt can be adjusted based on certain demand. With it, your filling process can be more efficient and productive.

3. Filling Nozzle

For an automatic liquid filling machine, the filling nozzle is a must have. Literally, the filling nozzle is the actual tool for filling the liquid. However,it’s not just a tool. It controls the direction of liquid flow as well as the accuracy of filling. For your successful filling, it plays a decisive role.

Based on how thick the liquid is, there is a wide range of filling nozzles to choose from. Common filling nozzles include straight-through nozzle, purge nozzle, and overflow nozzle.

Straight-through nozzles are the most common and versatile ones you can see on liquid filling machines. They can be used for filling so many kinds of liquid. Also, they feature a simple design that enables liquid flow smoothly.

Purge nozzles are mainly used to remove air from containers before or after filling. With them, degradation and contamination can be avoided to a great extent.

Overflow nozzles are designed to fill containers to a consistent level. These nozzles discharge the liquid into the container. Once the liquid product reaches a certain height, the extra liquid will flow back into the supply tank via the nozzles.

In some cases, you may need multiple nozzles to get your job done. But there is no worries, most filling machines are easy to change their nozzles.

4. Peristaltic Pump

As an essential component of liquid filling machines, the peristaltic pump uses silicone hoses to pump liquid. It features high accuracy and great stability. When the rollers starts running, the hose is squeezed. Along the hose, the liquid product will be carried from one end to the other.

What’s more, the peristaltic pump contributes to the entire filling process because of its excellent performance. It comes with high precision, which is an important feature for pharmaceutical industry. Besides, peristaltic pumps have mild nature and cause no foaming to the liquid product. Also, they are easy to clean and quick to disassemble.

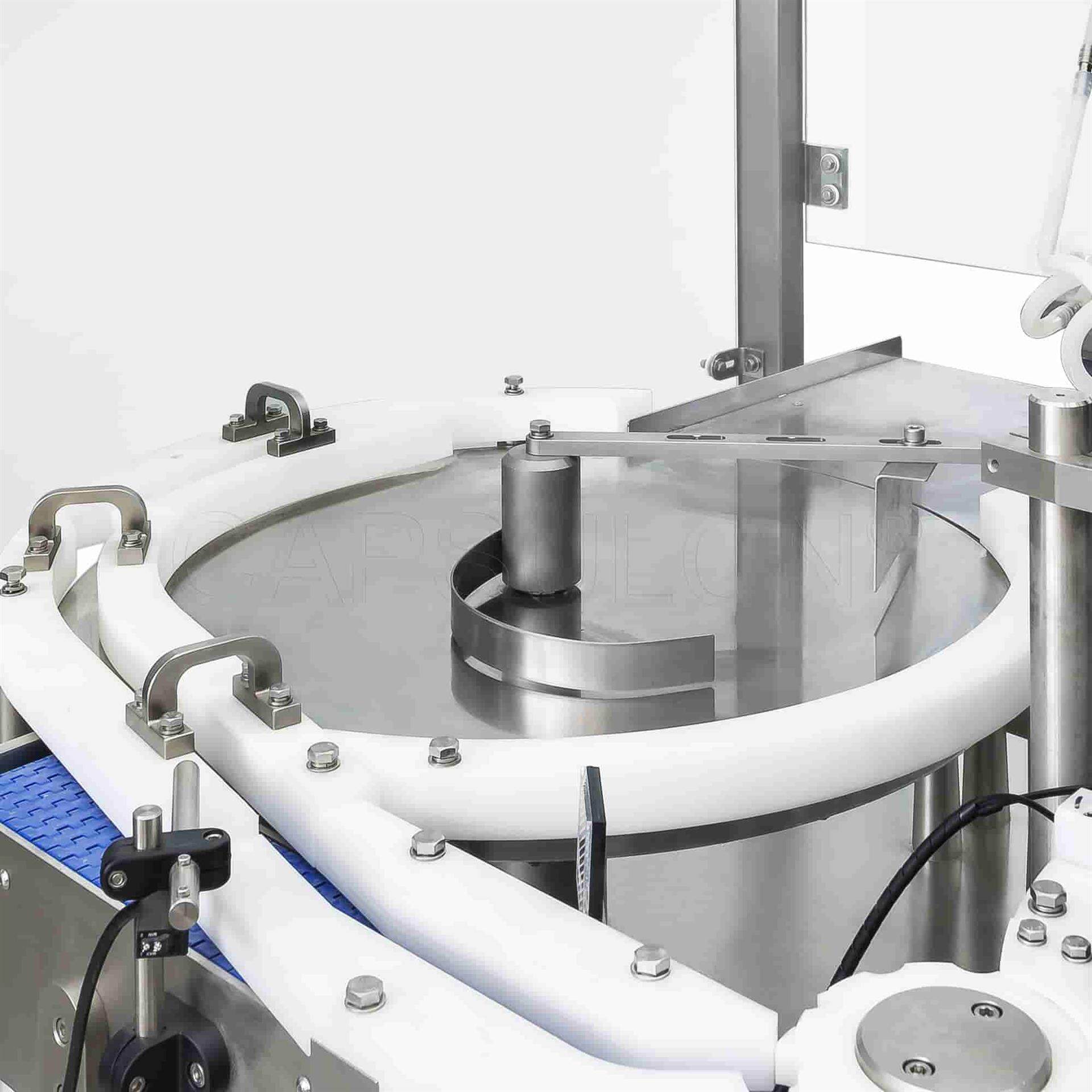

5. Main Turntable

The main turntable rotates the containers to each filling station. So it’s definitely an integral part for any liquid filler. It makes it possible to synchronize several filling steps. When one container is being filled, another is probably being capped at the same time.

Moreover, the turntable offers a stable platform for the filling nozzles, which guarantees that each container is filled precisely. When there are no bottles under the filling nozzle, the sensor installed above the turntable will detect it and stop the peristaltic pump from working.

6. Capping Mechanism

Normally, the capping mechanism is placed at the end of the liquid filling machine. Once the container is filled, it will be transported to the capping mechanism by the conveyor belt. After capping, the container moves to the next unit, ready for packaging and labeling.

The capping mechanism is one of the important components for a liquid filler. It ensures proper capping and perfect sealing. Furthermore, this helps avoid leakage and contamination.

7. PLC Control Screen

The PLC control screen is a device where all parameters are set and adjusted. Common settings include filling volume, filling speed, data memorization, and more.

By changing certain settings, the machine can react faster and more correctly to the real-time filling process. Every time the sensor detects an error with the filling volume, the PLC control system will send signals to the machine. Then, it will respond to add or decrease liquid volume.

The Bottom Line

If you've read through our guide for liquid filling machine parts, then you probably know more about this machine than most. Getting the right parts for your machine is for sure worth a try. At the end of the day, you will find it enhances the efficiency and accuracy for your filling business.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche