Milk Powder Packing Explained: Types, Equipment & Selection Tips

Milk powder is a popular product used by people of all ages. Thus, to keep its quality, proper packaging is very important. Good packaging protects the milk powder from moisture, air, and contamination. It also helps keep the product fresh during storage and shipping. When selecting the powder packaging, you should know

- What types do you know for milk powder packing?

- What machines are always used to pack milk powder?

- How to choose milk powder packaging for your business?

Four Common Types of Milk Powder Packing

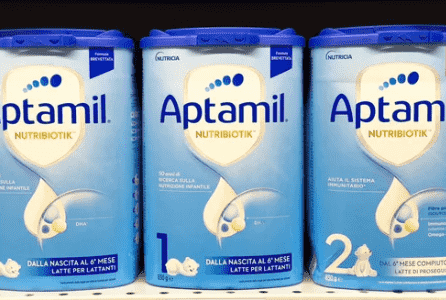

Tin Cans

Tin cans are widely used for packaging milk powder. They are mostly used for baby formula and high-end nutritional products. These cans are usually made of metal with a protective inner lining. This keeps the powder from reacting with the container. Tin cans often come with a foil seal and a plastic lid, offering a secure closure and a clean look. It also provides strong protection against moisture, oxygen, and light.

Tin cans are widely used for packaging milk powder. They are mostly used for baby formula and high-end nutritional products. These cans are usually made of metal with a protective inner lining. This keeps the powder from reacting with the container. Tin cans often come with a foil seal and a plastic lid, offering a secure closure and a clean look. It also provides strong protection against moisture, oxygen, and light.

This type of packaging is strong and durable, making it ideal for long-distance transport and storage. However, tin cans are more expensive than other packaging types. They are also less flexible in terms of shape and size. Despite these drawbacks, tin cans are still preferred for products that require a premium appearance.

Sachets and Pouches

Sachets and pouches are mainly made from multi-layer plastic films. They are commonly used for small amounts of powder, such as single-use servings or travel packs. Many companies also use stand-up pouches with resealable zippers for household use. Compared to rigid containers, sachets and pouches are more lightweight. They are also easy to store, and cost-effective to produce.

Sachets and pouches are mainly made from multi-layer plastic films. They are commonly used for small amounts of powder, such as single-use servings or travel packs. Many companies also use stand-up pouches with resealable zippers for household use. Compared to rigid containers, sachets and pouches are more lightweight. They are also easy to store, and cost-effective to produce.

However, they are not as durable as metal or plastic. This type of bags can be torn if not handled carefully. In addition, many sachets are not resealable. So it is harder to keep the product fresh after opening.

Plastic Jars

Plastic jars are another common packaging type for milk powder. These jars are usually made from food-grade plastic such as PET or HDPE. Moreover, they often come with screw-on or flip-top lids for reuse. Plastic jars are easy to open and close, making them convenient for daily consumption. Many milk powder suppliers choose this type because it can be shaped in various ways to meet branding needs. Transparent jars are popular. They allow users to see the product inside and check the quality like fineness directly.

Plastic jars are another common packaging type for milk powder. These jars are usually made from food-grade plastic such as PET or HDPE. Moreover, they often come with screw-on or flip-top lids for reuse. Plastic jars are easy to open and close, making them convenient for daily consumption. Many milk powder suppliers choose this type because it can be shaped in various ways to meet branding needs. Transparent jars are popular. They allow users to see the product inside and check the quality like fineness directly.

However, plastic jars require extra layers or coatings to provide enough protection against air and light. This increases the produciton costs. In addition, they also take up more space during shipping and storage compared to flexible pouches.

Glass Bottles

Glass bottles are not as common as other types of milk powder packaging. But they are sometimes used for special products or in niche markets. These bottles are usually made from thick, food-grade glass and come with airtight lids to keep the powder dry and safe. One of the main benefits of glass is its excellent barrier properties. And it does not react with the product. Glass also gives the product a clean, premium look that some brands use to attract customers.

Glass bottles are not as common as other types of milk powder packaging. But they are sometimes used for special products or in niche markets. These bottles are usually made from thick, food-grade glass and come with airtight lids to keep the powder dry and safe. One of the main benefits of glass is its excellent barrier properties. And it does not react with the product. Glass also gives the product a clean, premium look that some brands use to attract customers.

However, glass is heavy and fragile. This increases packaging and transport costs for secure shipping.

What Type of Machine is Used to Pack Milk Powder?

As sachets and puches cover a large market share, here introduces 5 common powder filling machines for your reference.

VFFS Packing Equipment

The VFFS machine forms a pouch from a flat roll of film, fills it with powder, and seals it. The entire process is conducted in one vertical direction. The VFFS system is compact and efficient, suitable for high-speed production lines. It can handle various pouch styles such as pillow bags, gusseted bags, or even stand-up pouches.

The VFFS machine forms a pouch from a flat roll of film, fills it with powder, and seals it. The entire process is conducted in one vertical direction. The VFFS system is compact and efficient, suitable for high-speed production lines. It can handle various pouch styles such as pillow bags, gusseted bags, or even stand-up pouches.

VFFS machines excel in its flexibility and speed. They can produce hundreds or even thousands of filled sachets per hour. This also helps reduce labor costs due to its high level of automation. This machine works best with free-flowing or semi-free-flowing powders. In addition, it may need extra features like dust control systems to handle fine products like milk powder.

Auger Fillers

The auger filling machine is one of the most commonly used machines for filling milk powder. It uses a rotating screw to dispense a precise amount of powder into containers. The filling volume can be controlled by adjusting the speed and rotation of the auger.

The auger filling machine is one of the most commonly used machines for filling milk powder. It uses a rotating screw to dispense a precise amount of powder into containers. The filling volume can be controlled by adjusting the speed and rotation of the auger.

This machine is often used in both semi-automatic and fully automatic packaging lines. It can handle a wide range of fill sizes, suitable for packing from small sachets to large tins. However, auger fillers need regular cleaning to avoid buildup of powder inside the screw.

Vacuum Filling Machines

Vacuum filling machines are used when high accuracy and hygiene are required. These machines use vacuum suction to pull the milk powder into a chamber, then release it into the container. This method is usually applied in small or expensive products like infant formula. Vacuum filling is slower than auger filling. But it is often used for sensitive products where quality is a top concern.

Vacuum filling machines are used when high accuracy and hygiene are required. These machines use vacuum suction to pull the milk powder into a chamber, then release it into the container. This method is usually applied in small or expensive products like infant formula. Vacuum filling is slower than auger filling. But it is often used for sensitive products where quality is a top concern.

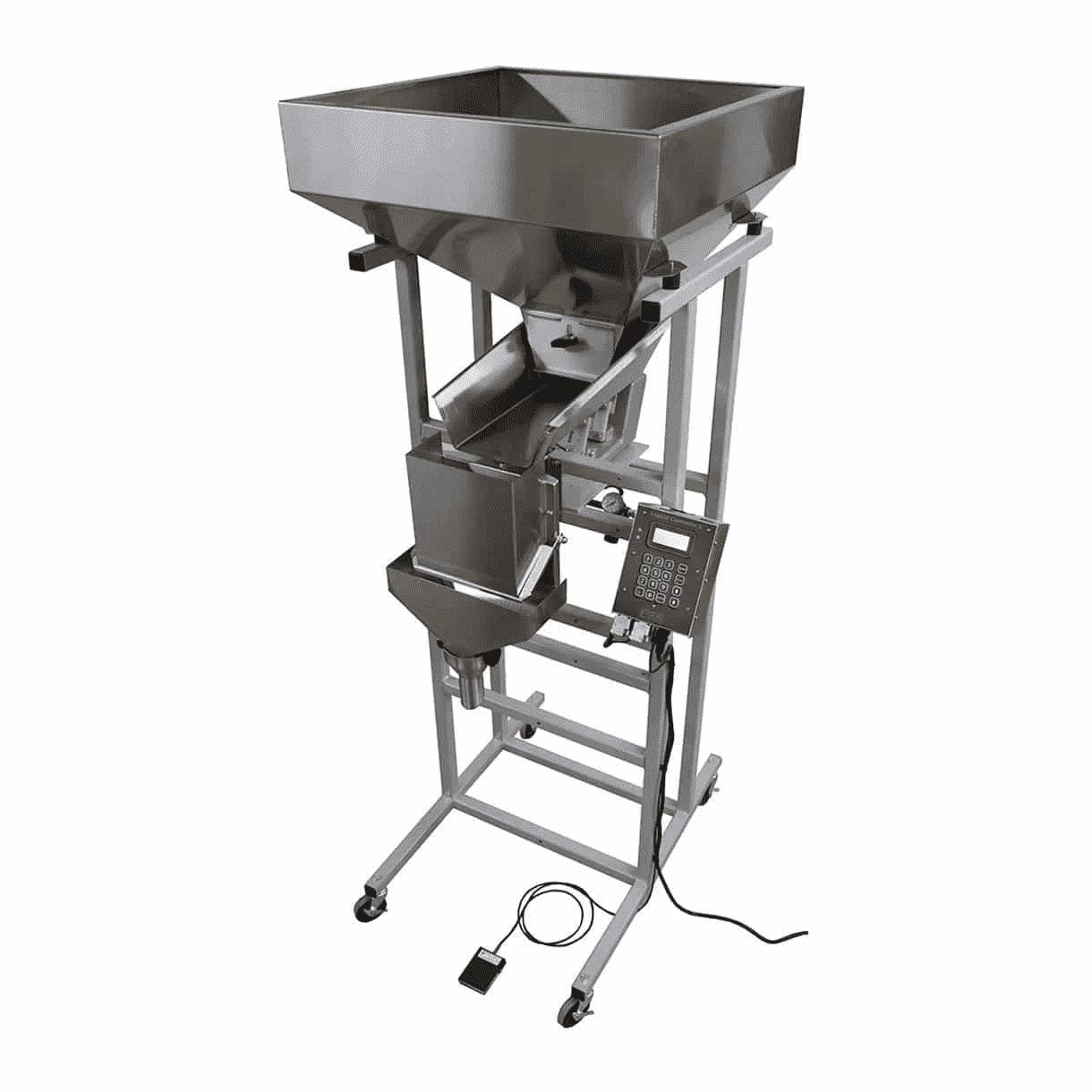

Net Weight Fillers

The machine uses a load cell to measure the exact weight of the milk powder. This type is ideal when weight accuracy is critical, such as in regulatory-controlled markets. Net weight fillers are often used in bulk filling operations. Compared to auger systems, these machines offer better control over product giveaway. But they may work more slowly.

The machine uses a load cell to measure the exact weight of the milk powder. This type is ideal when weight accuracy is critical, such as in regulatory-controlled markets. Net weight fillers are often used in bulk filling operations. Compared to auger systems, these machines offer better control over product giveaway. But they may work more slowly.

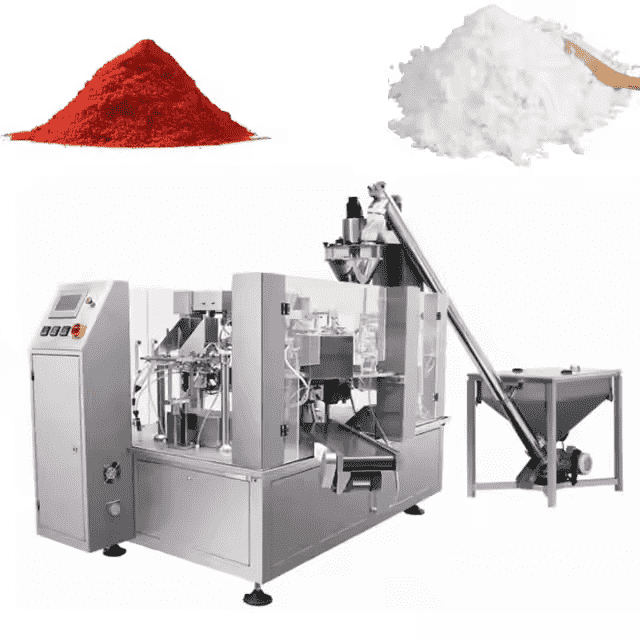

Rotary Filling Machines

A rotary filling machine has a circular layout. It is equipped with multiple filling heads that can rotate as the containers move. It features high-speed filling, ideal for large-scale production. Moreover, rotary systems can be combined with sealing and capping stations in your production line.

A rotary filling machine has a circular layout. It is equipped with multiple filling heads that can rotate as the containers move. It features high-speed filling, ideal for large-scale production. Moreover, rotary systems can be combined with sealing and capping stations in your production line.

How to Choose Suitable Milk Powder Packing for Your Business?

Product Type

If your product is baby formula or medical-grade nutritional powder, it will need much stronger packaging. It need to offer good protection against moisture, air, and light. In this case, tin cans or high-barrier plastic jars are often preferred. For general milk powder, such as full cream milk powder, more cost-effective options like pouches or sachets may be better.

Target Market

If you’re selling to individual consumers for home use, small to medium-sized packages such as 400g jars work well. If your product is for industrial buyers, such as bakeries or food manufacturers, bulk bags like 10kg are more appropriate. Single-use sachets are useful for customers who need convenience, such as travelers. So before making a packing, you need to research the market, and find a suitable packing type to meet your target customers’ needs.

Packing Material

Packing type also highly relates to the packing material. If the powder is sensitive to air and humidity, you’d better choose packaging made from metal, or multi-layer plastic film.

If you want to make sachets, multi-layer plastic films could be considered. The structure usually includes a PE layer, an aluminum foil layer, and a PET layer. Many manufacturers use this type to print various patterns and logos for more attraction.

The End

As a leading manufacturer in China, iPharMachine offers different powder filling machines. Based on production needs, you can choose semi-automatic or fully automatic models. We also provide customization for functions and patterns. We’ll discuss with you in every detail to meet your demand.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche