Pneumatic Vacuum Loader QVC-1: Working Principle

Vacuum loader is a vacuum conveying machine by using pneumatic vacuum pump as vacuum source. With the help of this vacuum loader, materials could be conveyed directly from container into mixer, tablet machine, packing machine, vibration sieve, granulator, capsule filling machine, granulator, disintegrator, etc. Using this machine could lighten workers’ labor intensity, put an end to powder pollution and ensure that the production process meets GMP requirements.

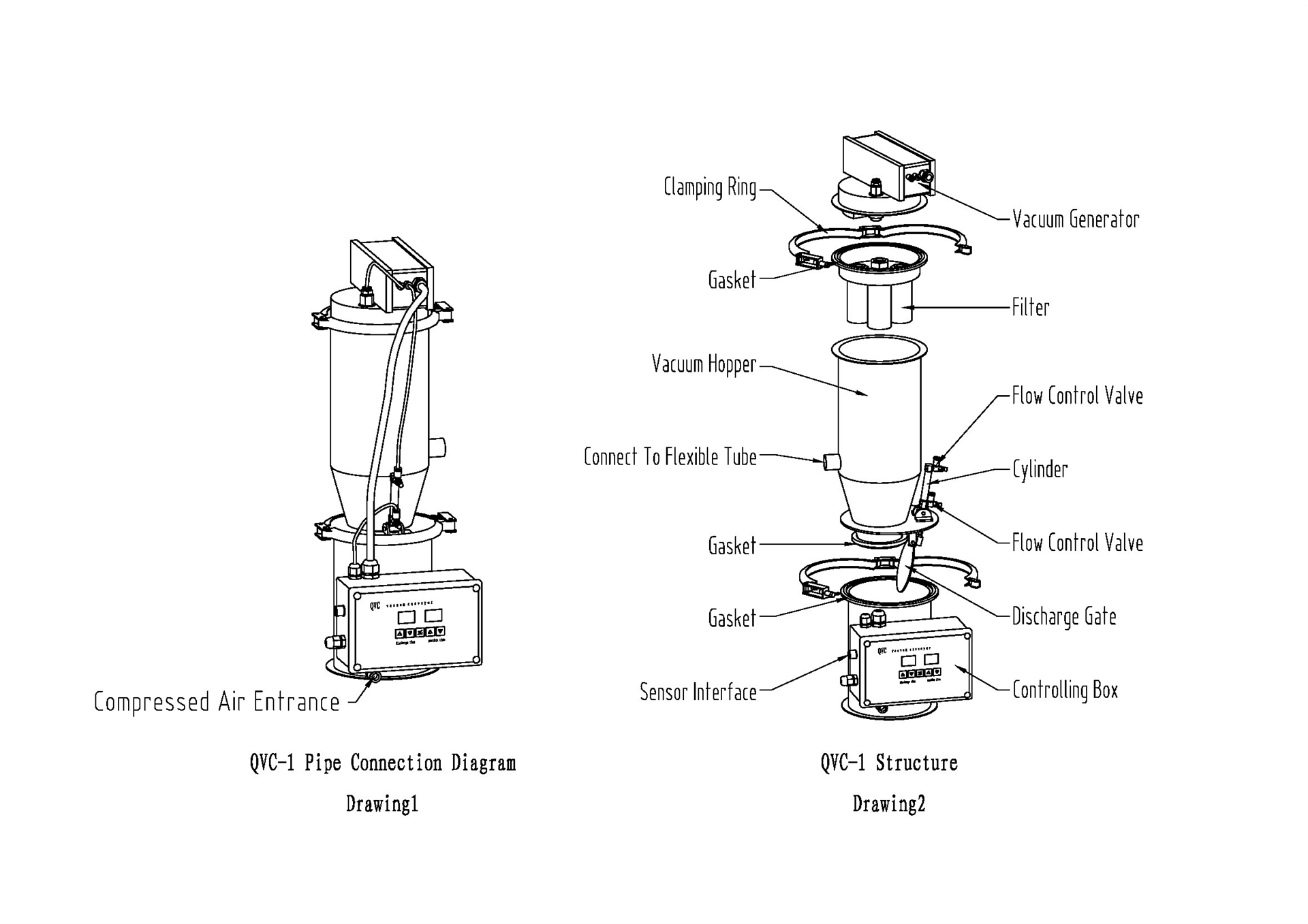

QVC-1 Structure:

Working Principle

When “ON/OFF” button is pressed, compressed air gets into vacuum generator and the discharge of the hopper, driven by pneumatic cylinder, is closed. Vacuum is established in hopper. Thus, an air current is formed under vacuum. Operated by this air current, material is conveyed to vacuum hopper via hose. After a period of time (feeding time, adjustable), compressed air is cut off. Pneumatic vacuum pump could not generate vacuum and the discharge of the hopper, driven by pneumatic cylinder, gets open. While the vacuum in hopper disappears, material is automatically discharged from the discharge into the receiving machine (such as tablet press and packing machine). Meanwhile, the compressed air stored in the air tank blows the filter in reverse to make the filter cleaned automatically. After a period of time (discharge time, adjustable), compressed air is restarted. In this way the conveyor works in cycles to make the material transferred into receiving machine continuously.

The automatic transferring of vacuum conveyor with material level control is realized with the hopper of the material-receiving machine through material level control. When the material level is higher than a position in the hopper of the material-receiving machine, vacuum loader stops conveying; when the material level is lower than a position in the hopper, vacuum conveyor starts working automatically.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche