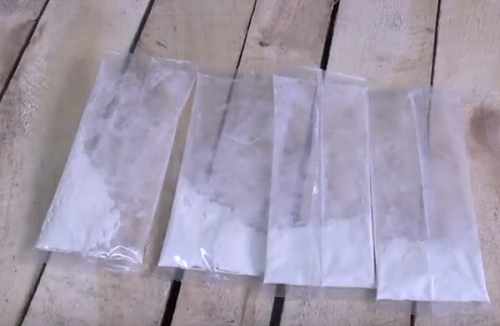

Powder Packaging Machine Maintenance Tips

In recent years, the powder packaging machine market has maintained rapid growth. they are widely used in both food and pharmaceutical industries. On the basis of the past, the powder packaging machine is constantly self-improving, aiming at humanized operation and paying attention to the perfect combination of product quality and appearance, which greatly saves the labor cost and improves the production quality.

However, there are many companies that do not understand the importance and maintenance of powder packaging machines. After purchasing the powder machinery, pay attention to its daily maintenance to ensure the normal operation of the equipment and extend the service life of the equipment.

1. Lubrication

It is necessary to regularly lubricate the gear meshing parts of the gears, the bearing oil filling holes, and the moving parts with oil. The gearbox is strictly prohibited from running without oil. When filling the lubricating oil, be careful not to put the oil tank on the rotating belt to prevent slipping or premature aging of the belt.

2. Maintenance

Before using the powder packaging machine, check the screws of each part and be sure that they do not loosen. Otherwise, it will affect the normal operation of the whole machine. For the electrical parts, pay attention to waterproof, moisture-proof and anti-corrosion work to ensure that the electrical control box and the wiring port are clean to prevent electrical failure. After the machine is shut down, the two air heaters should be in the open position to prevent the packaging material from being burnt.

3. Clean

After the equipment is shut down, the metering part should be cleaned in time, and the air heater should be cleaned frequently to ensure the sealing line of the packaged product is clear. The scattered materials should be cleaned up in time to facilitate the cleanliness of the parts, thus better extending their service life. At the same time, the dust inside the electric control box should be cleaned frequently to prevent electrical faults such as short circuit or poor contact.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche