Solid-ink Coding Band sealer FRD-1000: Adjustment Methods of Each Component

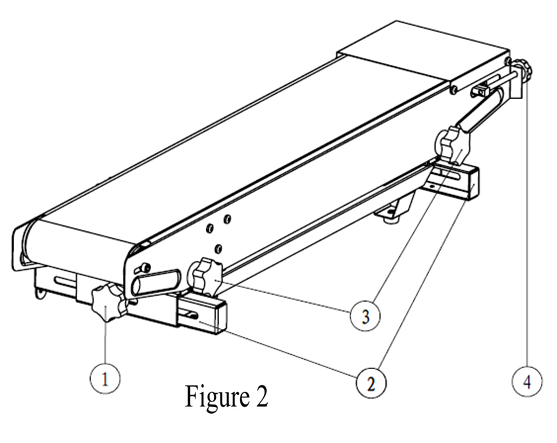

Adjustment method of Conveyor part

- Adjusting fasten knob

- Foot stool

- Fasten knob

- Conveyor belt tension wheel adjustment screw

Conveyor belt tension adjustment: when the conveyor belt is too loose or too tight, adjusting conveyor belt tension wheel adjustment screw ④ of two sides (right rotation is to be tight, left rotation is to be loose), until the tightness of conveyor belt is appropriate.

Conveyor worktable front and back fine adjustment: when the conveyor worktable needs front and back adjustment. first to loosen adjustment fasten knob ① of both sides, then push or pull the worktable, tighten the two sides adjustment fasten knob ① until the position is suitable.

Conveyor worktable up and down fine adjustment: when the conveyor worktable needs up and down adjustment, first to loosen two sides fasten knob ③,then pull the worktable up or down, tighten the two sides fasten knob ③ until the position is suitable.

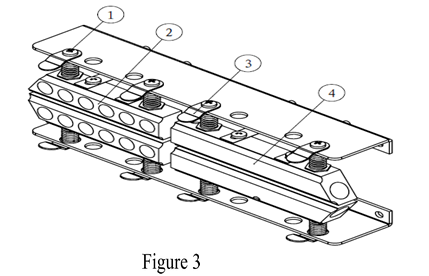

Adjustment method of sealing parts

- Adjustment screw

- Cooling block

- Lifting piece

- Heating block

Distance adjustment of Up and down heating block & cooling block: because of different sealing material and thickness, each kind of product needs to adjust the distance between heating block and cooling bock.

The method is described as follows: right-handed rotation adjustment screw ① can increase the distance between up and down heating blocks and cooling blocks, Left-handed rotation adjustment screw ① can decrease the distance between up and down heating blocks and cooling blocks.

Sealing belt replace method & adjustment: after the heating block cool down, take down the protective cover, rotating the lifting piece ③ into 90°which on the heating block and cooling block in Figure 3, then loose the embossing wheel and the spring of middle pressure wheel, take down the leading belt, then push driven wheel in the direction of the heating block, and take down the sealing belt and replace with new sealing belt. Finally adjust the position back of driven wheel, heating blocks, cooling blocks and embossing wheel.

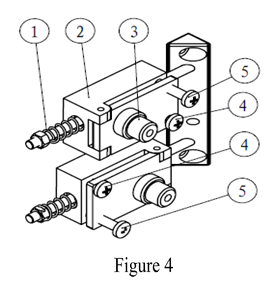

Driven belt roller adjusting blocks

- Spring

- driven belt wheel seat

- driven wheel seat

- Adjusting screw

- Adjusting screw

If the sealing belts have phenomenon of off tracking, it can adjust the adjusting screw of driven belt wheel seat ②.

More information click Continuous Band Sealer to view.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche