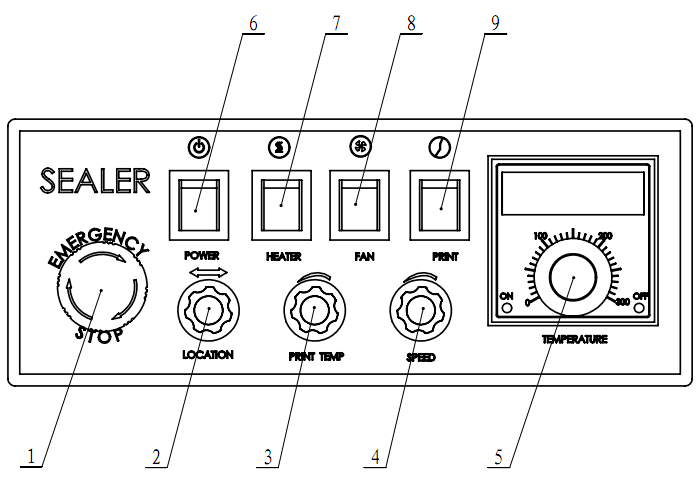

Solid-ink Coding Band sealer FRD-1000: Panel Function

- Urgent stop switch: under emergency status, disconnect the power supply.

- Sealing speed: adjusting the running speed of sealing belts.

- Printing temperature adjustment: Adjusting temperature of solid-ink roller heating block.

- Printing position adjustment: Adjusting the position of solid ink coding.

- Sealing temperature adjustment: adjust and control the temperature of heating block.

- Power switch: Control the whole machine on or off.

- Sealing heating: Control the power of heating block on or off.

- Cooling: Control the cooling fan on or off.

- Printing heating: Control the solid ink heating block on or off

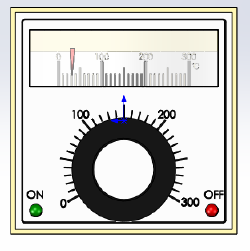

Temperature controller setting methods:

A. Rotating the screw scale into needed working temperature

B. The temperature which display in the dial is the actual temperature of working.

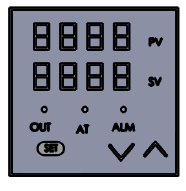

If you order our band sealer with intelligent temperature controller, intelligent temperature controller setting methods:

A. Upper number display (red) is real temperature; bottom number display (green) is setting temperature

B. Press the button SET in lower left, at this moment the bottom number (green) turns into flashing.

C. Then press button p increase or button q decrease, to set the required temperature. This temperature should be set which is based on the thickness of plastic film, normally the temperature set as about 150℃.

D .When the temperature is set, must press the button SET again to return it back to normal status, then put into working.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche