Your Essential Guide to Sustainable Pharmaceutical Packaging

Sustainability isn't just a buzzword anymore—especially in pharmaceutical and nutraceutical packaging. It's now a top priority.

Today's manufacturers want packaging that's eco-friendly, reduces waste, and still keeps products safe. But how do you do that?

In this post, you'll learn what sustainable pharmaceutical packaging really means and why it matters. We'll cover the benefits you get, materials you can choose, and how to switch to greener packaging. Plus, we'll discuss the challenges you might face along the way, and look at some of the latest trends.

Ready to make your pharma packaging greener? Let's jump in!

What is Sustainable Pharmaceutical Packaging?

Simply put, sustainable packaging is all about protecting the environment without compromising product safety. It uses eco-friendly materials and smarter designs to reduce waste, carbon footprint, and resource use.

But sustainable packaging in the pharmaceutical industry must still meet all the strict safety and quality requirements for medications and supplements. It just does this in a greener way.

Why does this matter?

Traditional pharma packaging is usually single-use plastic. It's complicated to recycle. So millions of blister packs, bottles, and wrappers end up in landfills and oceans. They can stay there for centuries. This causes serious environmental problems.

With concerns about plastic pollution rising, regulators and customers want better solutions. Switching to sustainable packaging isn't just good for the planet—it's also becoming crucial for your company's reputation.

Materials Used in Sustainable Pharmaceutical Packaging

Manufacturers have an expanding toolkit of eco-friendly packaging materials. Key examples include:

Reusable & Refillable Materials

|

Glass Bottles |

Durable containers that can be cleaned and reused many times. |

|

|

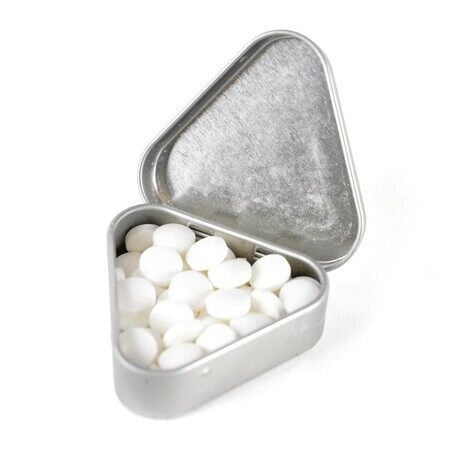

Metal Tins |

Strong, reusable containers ideal for refilling or repurposing. |

|

|

Rigid Plastics |

Durable plastics designed to withstand multiple uses and cleanings. |

|

|

Aluminum Bottles |

Lightweight, strong, and easy to sanitize containers suitable for reuse. |

|

Reuse is less common in pharma due to safety concerns, but some innovative approaches exist. Some companies have even introduced refillable medicine bottles that patients can reuse for refills.

And in distribution, durable, returnable shipping containers can replace single-use packaging, significantly cutting waste if managed properly.

Recyclable & Recycled Materials

|

Glass |

A reusable and recyclable option for certain pharmaceutical products. |

|

|

PET Plastic |

A widely recycled plastic, lightweight and versatile. |

|

|

HDPE Plastic |

Strong plastic commonly recycled into bottles or containers. |

|

|

Recycled Cardboard |

Paper-based material made from recycled fibers, easy to recycle again. |

|

|

Aluminum |

Highly recyclable material often used for blister packaging. |

|

|

Paperboard |

Lightweight paper-based material, easily recyclable. |

|

Traditional materials like glass and aluminum are infinitely recyclable and commonly used in vials and blister foils. Plastics can be made more recyclable using single-material (mono-material) packaging designs. For instance, making an entire blister pack out of one type of plastic instead of layered plastic and foil.

Using materials with recycled content is another strategy: PCR (post-consumer recycled) plastics or recycled cardboard can be turned into new pill bottles, cartons, and shipping boxes. Paper and cardboard are popular for secondary packaging because they are renewable, recyclable, and biodegradable.

Biodegradable & Compostable Materials

|

PLA (Polylactic Acid) |

Bioplastic derived from plant sugars; compostable under industrial conditions. |

|

|

Mushroom Packaging (Mycelium) |

Made from fungi, fully compostable and breaks down naturally. |

|

|

Starch-based Materials |

Packaging made from starch (corn, potato), fully biodegradable. |

|

|

Sugarcane Bagasse |

Fibrous residue from sugarcane, compostable and biodegradable. |

|

These materials decompose naturally over time, reducing long-term pollution. For example, PLA (polylactic acid) made from corn starch can decompose in months under the right conditions. Even seaweed-based packaging films are being tested as alternatives.

One pharma company (Astellas) even uses a plastic derived from sugarcane for its pill blister packs, showing that plant-based packaging can work in medicine.

Benefits of Sustainable Packaging in the Pharmaceutical Industry

Using sustainable packaging is a great way to help protect the earth. If you're a pharmaceutical manufacturer, you can benefit too. Check out these key advantages:

Better for the Environment

Recyclable, biodegradable, or reduced packaging creates less waste. Less waste means smaller landfills and fewer resources wasted. Using fewer plastics also means conserving natural resources. All these steps help your business reduce its environmental footprint.

Lower Costs in the Long Run

Sustainable packaging can save your company money. Minimal or lightweight packaging uses less material. Less material means lower shipping costs. Cutting waste also reduces disposal fees and boosts efficiency. Over time, these savings often cover your upfront investment.

Meet Regulations and Customer Expectations

Sustainable pharmaceutical packaging keeps your business ahead of regulations. Governments are pushing for greener packaging. For example, the EU plans to make all packaging recyclable or reusable by 2030. Going green now helps you avoid future penalties.

Plus, customers are increasingly eco-conscious. Around 70% of consumers are inclined to pay more for packaging that is environmentally friendly. Offering greener packaging builds your brand's image and appeals directly to these green-minded customers.

How Pharmaceutical Manufacturers Can Achieve Sustainable Packaging

Transitioning to sustainable packaging is a step-by-step process. Key steps to consider include:

1. Check Your Current Packaging and Set Clear Goals

First off, check the packaging you use now. Identify what's recyclable and what's not. Look closely at how much waste you're creating. Then, set clear goals, like using 50% more recycled materials or getting rid of all non-recyclable packaging by 2025.

2. Redesign and Source Eco-friendly Materials

Redesign your packaging to use fewer materials. Simple designs, like using just one type of material, make recycling much easier. Choose eco-friendly options, like biodegradable films or recycled paperboard. Work with suppliers who know sustainable packaging. Their expertise can help you find materials that are both eco-friendly and safe for medicines.

3. Test Carefully and Ensure Compliance

Before using new packaging, test it thoroughly. Make sure it keeps medicines safe and stable. Check for chemical interactions and shelf-life issues. Confirm that it meets all industry regulations. Changing your main packaging might need regulatory approval. So, involve your quality and regulatory teams right from the start.

4. Start Small, Get Feedback, and Refine

Train your team on how to handle the new materials. Roll out the changes gradually—maybe start with just one product. Pay attention to how it goes. Gather feedback from your team and customers. Measure results, like reduced waste and cost savings. Use what you learn to make adjustments. Keep improving, and you'll get the most benefit over time.

Challenges and Solutions for Transitioning to Sustainable Pharmaceutical Packaging

Of course, shifting to a new packaging solution comes with some challenges. But don't worry, you can manage them with the right approach. Let's look at the main issues and how you can handle each one:

1. Higher Initial Costs

Eco-friendly materials or new packaging designs can be more expensive initially. You might also need to invest in new machinery or tooling.

- Solution:

Test sustainable packaging on one product first. Measure savings like reduced material usage, lower shipping costs, or decreased waste disposal fees. Once you see positive results, scale up gradually.

Look into flexible financing or leasing options instead of buying new equipment. Partnering with suppliers or sustainable packaging experts can also help lower initial costs through better sourcing and design recommendations.

2. Strict Safety and Regulatory Requirements

Pharma packaging must meet strict safety standards. Switching to a new material requires approval from authorities (like FDA or EMA). Plus, not all eco-friendly materials keep your product as safe as traditional ones, so extensive tests are needed.

- Solution:

Partner with suppliers who specialize in pharma-grade sustainable packaging. They can suggest materials that already have some regulatory approval or testing.

Also, start the regulatory approval process early. Consider switching packaging gradually, starting with secondary or outer packaging first.

Finally, stay in close communication with regulatory bodies. They can provide guidance and clarify expectations, making the approval process smoother.

3. Limited Availability

Some sustainable materials (e.g., certain bioplastics) might not be widely available yet. Or they have limited suppliers. This can make sourcing a challenge.

- Solution:

Identify multiple reliable suppliers early. Don't rely on just one source for sustainable materials. Build relationships with these suppliers to ensure steady availability.

4. Recycling and Disposal Challenges

Some eco-friendly materials need specific conditions for recycling or composting. Local recycling centers may not handle them yet.

- Solution:

Collaborate with local recycling centers or waste management services. Ask them directly what materials they can handle.

Clearly label your packaging with recycling instructions. Educate customers on how and where to recycle your packaging correctly.

The Future of Sustainable Packaging in the Pharmaceutical Industry

The move toward sustainable pharmaceutical packaging is picking up speed. Here are some key trends worth your attention:

(Image Source: SYNTEGON)

(Image Source: SYNTEGON)

- Industry commitments and partnerships

Pharmaceutical companies are making bold sustainability pledges.

For instance, Novartis has committed to reducing PVC in packaging by 2025.

One collaboration led by PA Consulting and PulPac is developing a recyclable paper-based blister pack to replace traditional plastic/foil blisters.

- Regulatory pressure and consumer expectations

Governments are introducing policies to make packaging greener.

The EU, for example, has set a goal for 2030, mandating that all packaging should be recyclable or reusable. This will drive pharma companies to redesign packaging for compliance.

Meanwhile, consumers will continue to favor brands with eco-friendly packaging, making sustainability a competitive necessity rather than a nice-to-have.

- Innovation in materials and technology

The future will bring new solutions that make sustainable packaging easier.

Breakthroughs in bio-based materials (like algae-derived plastics or improved compostable polymers) are on the horizon. They may offer the same protection as current plastics with far less environmental impact.

Recycling technologies are also improving. This means materials that are hard to recycle today could become recyclable tomorrow.

We'll also see more digital integration. For example, QR code labels on packages (already encouraged in the EU) can reduce the need for paper inserts.

Over time, these innovations will make sustainable practices standard in pharma packaging.

Final Thoughts

Sustainable pharmaceutical packaging is the future. More companies are switching to eco-friendly materials and smarter designs to cut waste and reduce their impact on the planet.

Sure, the transition isn't always easy. It takes time, effort, and sometimes extra costs. Yet, in the long term, it proves to be worthwhile. Less waste, lower costs, happier customers, and fewer headaches with regulations.

The good news? Sustainable packaging is getting easier and more affordable. New materials and smarter solutions are popping up all the time. Now's the perfect time to make the switch and stay ahead in the game.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche