A Beginner's Guide to Tube Filling Machine Troubleshooting

There's a pile of production orders sitting on your desk. Your tube filling machine suddenly starts to act strange in the middle of the night shift. Unfortunately, the clock is ticking, but you don't have any backup plan for the failure. Have you ever experienced such frustration?

It's normal to panic when a machine acts weird all of a sudden, especially if you're the one handling the operations. Most machine faults are caused by human error and poor maintenance. So, before you call a technician, let's see how you can quickly identify and resolve common problems with your tube filler on your own.

10 Troubleshooting Steps for Tube Filling Machines

In this section, we will share a few general steps for troubleshooting machine problems. No matter what type of tube filling machine you're using, following these steps can help you solve many common issues.

STEP 1 Turn off your tube filling machine before you start troubleshooting. Follow LOTO procedures to ensure a safe working environment.

STEP 2 Check if there are any blown fuses or loose connections. If found, replace or tighten it. Use a multimeter to measure voltage to see if it's within the expected range.

STEP 3 Ensure the compressed air supply is working properly. Inspect the pneumatic system to check if there are any leaks.

STEP 4 Confirm that your tube filling machine can accommodate the tube material you're using. Check the tubes for defects or contaminants. If found, replace or clean it.

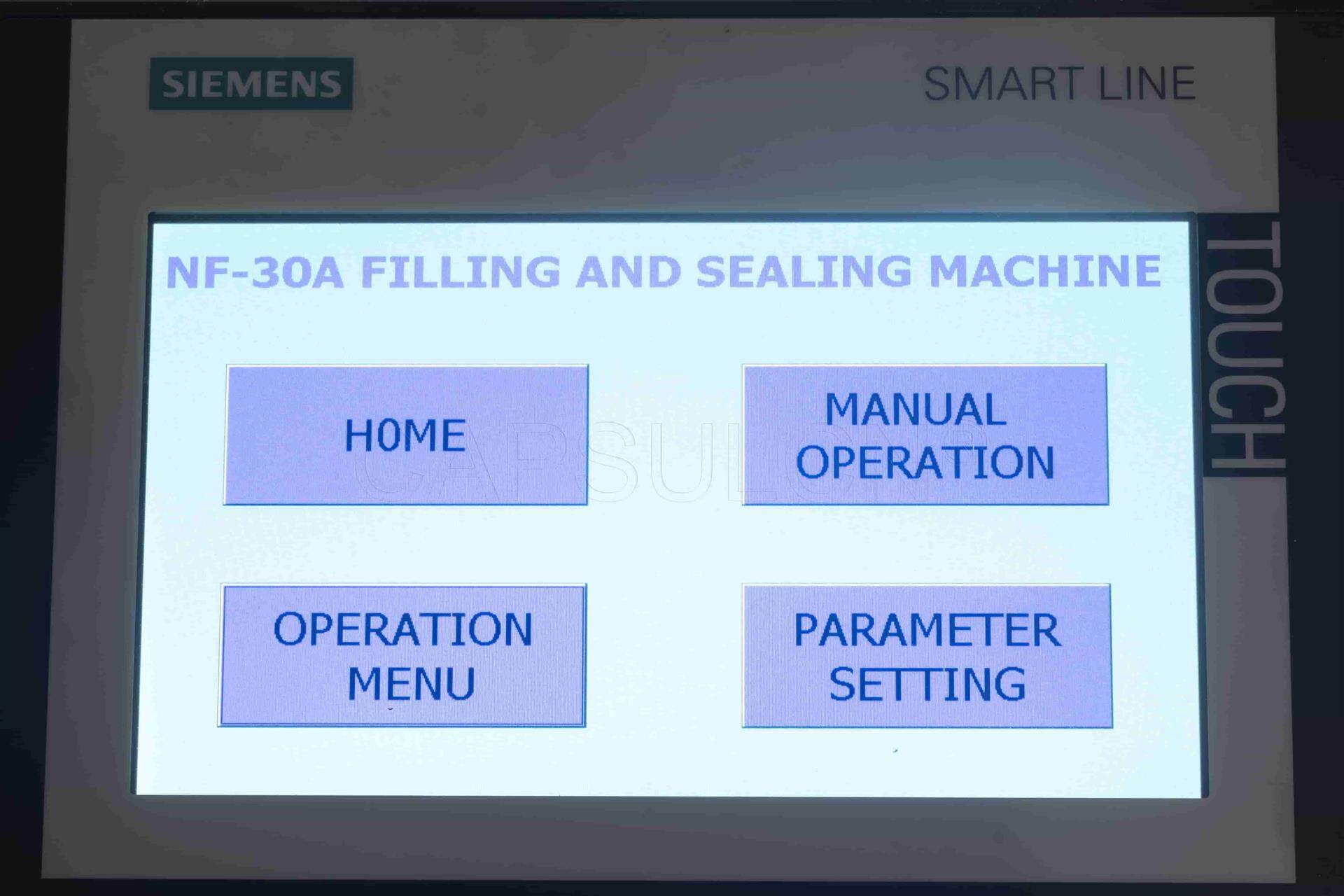

STEP 5 Check your machine settings, such as the filling volume, speed, and temperature. Make adjustments if necessary.

STEP 6 Inspect the key components of a tube filling machine.

- Identify any clogged or damaged filling nozzles. If found, clean or replace it.

- Ensure the turret can rotate smoothly without misalignment.

- Check if the sealing jaws are properly aligned.

- Ensure each sensor is functioning properly. Replace any failed ones.

STEP 7 Inspect your lubrication schedule to see if the machine's moving parts are regularly lubricated. Replace any worn-out parts.

STEP 8 Review your maintenance records to identify if the issue has happened before.

STEP 9 Ask the manufacturer or supplier for help if the issue persists. Be sure to provide detailed information about the issue.

STEP 10 Document each problem and solution for future reference. Also, carry out training to keep your team well-versed with the operation and troubleshooting procedures of the tube filling machine.

Common Tube Filling Machine Problems and Solutions

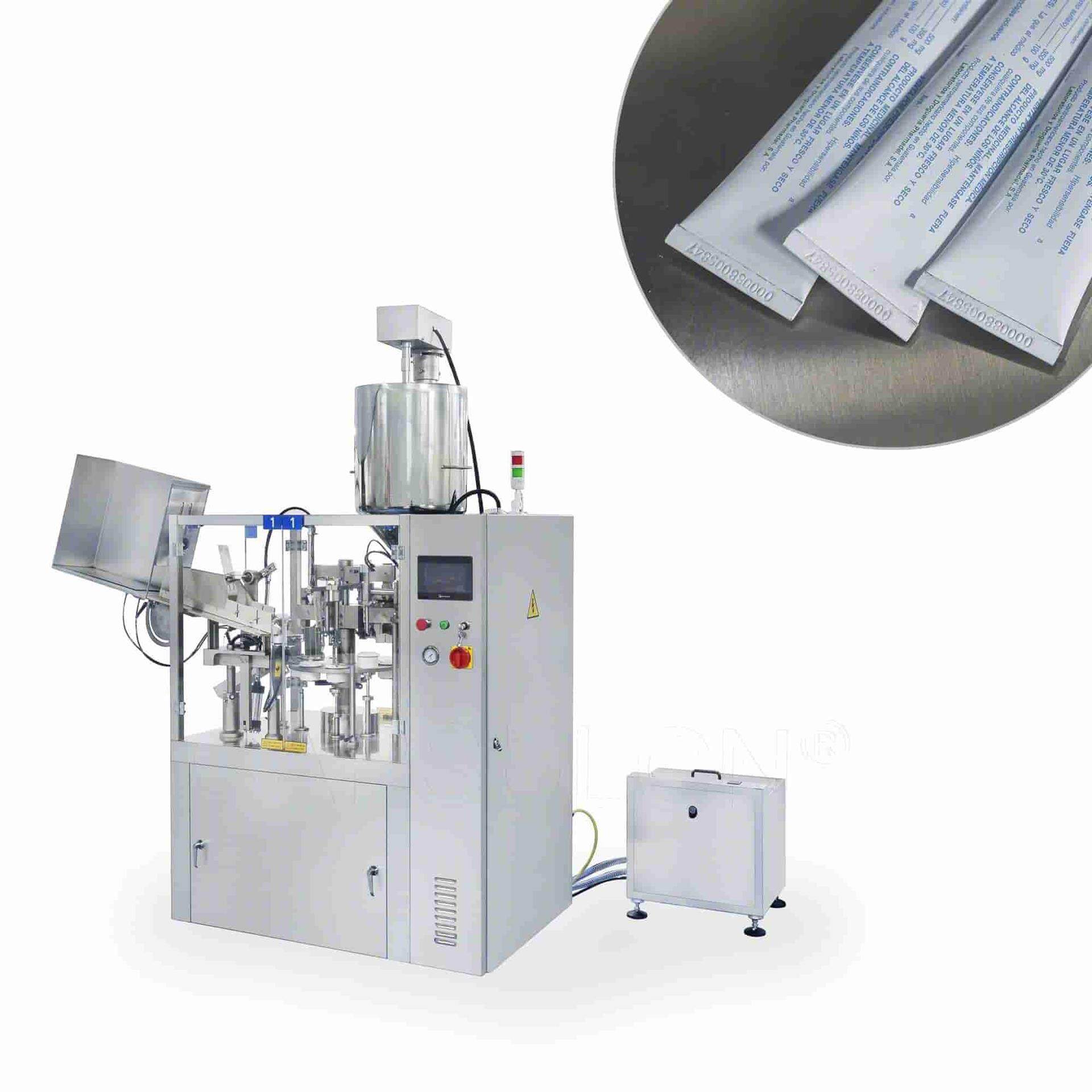

Tube filling machines can be classified into manual, semi-automatic, and fully automatic models. The latter two often encounter problems as they have many complex parts and components. Here are two tube filling machines that are popular across a wide range of customers. Let's take a glance at how to troubleshoot their problems.

- iPharMachine CNF-30A Semi-Automatic Tube Filling and Sealing Machine

|

Problems |

Possible Causes |

Solutions |

|

Temperature control display shows 4 "Hs." |

A thermocouple wire failure. |

Turn off the power. |

|

The heating temperature does not rise. There is a clicking sound from the relay. The heating current is not displayed. |

The heating element is burnt out or has poor contact. |

Replace with spare parts if available. |

|

The turret rotates, but the cylinder does not actuate, meaning there is no sealing action. |

Sealing start button not turned on or pneumatic circuit fault. |

Check the pneumatic circuit. |

|

Failure in the pneumatic mechanical valve corresponds to the distribution cam's innermost side. |

Replace the valve. |

|

|

Sealing but no filling. |

Failure in the pneumatic mechanical valve corresponds to the distribution cam's outermost side. |

Replace the valve. |

|

Infrared probe damaged or improperly adjusted. |

Adjust or replace the probe. |

|

|

The pilot 5/2-way solenoid valve (inside the machine) is damaged. |

Replace the 5/2-way solenoid valve. |

|

|

Fault or damage in the filling mechanical valve. |

Replace the valve. |

- iPharMachine NF-60Z Automatic Tube Filling and Sealing Machine

|

Problems |

Solutions |

|

Cylinder not working. |

Check if the emergency stop button is stuck. |

|

Confirm if the air supply switch is turned on. |

|

|

Check if the one-way signal valve is damaged. |

|

|

Tube misalignment. |

Check for the angle and distance between the photoelectric sensor and the tubes. |

|

Adjust the sensitivity of the photoelectric sensor. |

|

|

Check for any photoelectric sensor damage. Replace it if needed. |

|

|

Inaccurate filling or no filling. |

Inspect if the flow control valve is closed. |

|

Check if the filling rotary valve is open. |

|

|

Ensure there is sufficient material in the hopper. |

|

|

Check for sealing at various connection points. |

|

|

Unclear code printing. |

Check if code characters are correctly and securely installed. |

|

Check if the characters are worn out. Replace them if necessary. |

How to Use and Maintain a Tube Filling Machine Correctly

As mentioned above, most machine failures or breakdowns are a result of user error or neglected maintenance. To ensure you get the most out of your tube filling machine, here are some tips for using and maintaining the machine.

6 Tips on How to Use Tube Filling Machines

1. Read the user manual thoroughly prior to operating the machine.

WHY: This helps you gain a clear understanding of the machine's safety precautions, specifications, features, and other essential information.

2. Clean, inspect, and calibrate the machine.

WHY: Cleaning ensures no contaminants or debris could impact the filling and sealing. Damaged or worn-out components could lead to machine breakdowns, so inspection is crucial. Tube filling machines comprise a lot of parts and components. Calibration is required to keep the machine running smoothly to ensure each is in the right position.

3. Check for tubes to be filled.

WHY: This ensures tubes are free from contamination or defects. To put it simply, this step guarantees the quality of your final product.

4. Set up filling and sealing parameters.

WHY: To achieve your production target, the machine parameters should be set up or adjusted based on the tube format and filling material. Parameters include:

- Operating mode selection.

- Desired output.

- Filling volume and speed.

- Other functions relating to filling and sealing.

5. Monitor the filling and sealing operations.

WHY: Although the filling and sealing processes are automated, monitoring is still required to ensure everything goes smoothly in the machine. In case of any malfunctions, you can address them promptly.

6. Clean and inspect the machine after each shift.

WHY: Cleaning the machine thoroughly after each use can prevent contamination. When each bath is complete, checking the machine can ensure it's ready for the next run.

6 Tips for Tube Filling Machine Maintenance

1. Clean the machine on a regular basis.

WHY: The rotary turret and filling nozzles are where excess products are susceptible to building up. Regular cleaning helps prevent contamination, ensuring product quality.

2. Lubricate moving parts regularly.

WHY: A tube filling machine consists of numerous wear-prone moving parts. Sufficient lubrication is critical to keep each part in tip-top shape. Note: Be sure to use a lubricant compatible with the machine components.

3. Inspect sealing jaws, electrical components, and safety features.

WHY: Sealing jaws play a key role in the sealing process. These mechanisms are typically composed of two parts. So, alignment of the two parts is important to the sealing effect. Inspect and fine-tune them if needed. Additionally, electrical components are essential for the functioning of electrical equipment. Any faulty components must be replaced promptly. Safety features such as photoelectric sensors and emergency stop buttons can also impact the machine's operation.

4. Conduct operator training.

WHY: Operators are on the front line using the tube filling machine. They must be equipped with expertise in the machine's operation, troubleshooting, and maintenance. Adequate training can help them resolve common problems at the very beginning.

5. Keep maintenance logs.

WHY: A comprehensive maintenance log is a document that records all maintenance activities, dates, parts replaced, and any issues solved. The logs help identify recurring problems quickly.

6. Track spare parts inventory.

WHY: During maintenance, replacement is inevitable. Management of spare parts inventory is very important. This ensures that components are available in case of unexpected failures.

Final Word

Troubleshooting tube filling machines can be challenging, but with the steps and tips we shared in this post, you can identify and fix unexpected issues quickly. With some knowledge, troubleshooting issues with your tube filling machine can be made easier. And to learn more about tube filling and sealing machines, contact us today.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche