Lab Mixers for Pharma: 5 Common Types & 3 Considerations

Mixing machines are necessary tools in the lab. They are used to prepare samples, create solutions, and ensure material uniformity in research and experiments. The right mixer can make a big difference in the consistency and quality of results. In this article, we will explore futher about laboratory mixers.

- What are laboratory mixers?

- What are popular types in the market?

- How to choose a mixer for your samples?

What are lab mixers?

These mixing equipment can combine, blend, or homogenize different substances to achieve a uniform mixture. These substances can range from liquids, powders, and gels to even delicate biological samples. Laboratory mixers typically work by applying mechanical energy to the sample to create motion. This motion helps to break up clumps, and dissolve solid particles in liquids. They are widely used in a range of fields。 Common examples are listed below.

Applications of lab mixers

Pharma industry

In pharmaceutical labs, mixers are used to combine APIs with excipients. They work together to create uniform formulations for tablets, capsules, and liquid drugs. Consistent mixing ensures accurate dosages and effectiveness in the final product.

Chemical areas

In the production of chemical compounds, mixers are used to blend raw materials or reagents for consistent reactions. Common materials include solvents, catalysts, and other chemicals. Moreover, lab mixing equipment are applied for polymerization and solvent removal.

Biotechnology and life sciences

In cell culture labs, mixers are used to prepare nutrient media. This ensures that all components are well-dissolved and evenly distributed for cell growth. This equipment can also break down biological tissues or cells to extract proteins, DNA, or RNA.

Food and beverage industry

Mixers combine various ingredients, such as flour, sugar, oils, etc. When making emulsions, such as mayonnaise, or sauces, mixers help break down fat droplets into tiny particles.

Cosmetic areas

Mixers are essential in the cosmetic industry. They combine oils, emulsifiers, and water to create creams and lotions. Some products like facial serums also need even mixing for high quality. In addition, mixers can create custom colors for products like lipsticks, foundations, and eyeshadows. These mixers ensure that the pigments are well-integrated into the base materials.

What are the different types of laboratory mixing equipment?

Mixers have different types. Each type is designed for specific tasks. Here are some common examples for your reference.

Magnetic stirrers

This device is simple in design but effective for small to medium volumes. The basic setup includes a flat platform and a small magnetic bar. The platform contains a rotating magnetic field underneath. When the magnetic field rotates, it causes the stir bar to spin. This stirs the liquid without any direct mechanical connection. Magnetic stirrers are often used to dissolve solids into liquids, prepare buffers, and keep solutions homogeneous during experiments.

This device is simple in design but effective for small to medium volumes. The basic setup includes a flat platform and a small magnetic bar. The platform contains a rotating magnetic field underneath. When the magnetic field rotates, it causes the stir bar to spin. This stirs the liquid without any direct mechanical connection. Magnetic stirrers are often used to dissolve solids into liquids, prepare buffers, and keep solutions homogeneous during experiments.

However, magnetic stirrers also have some limitations. They are not suitable for mixing large volumes or very viscous liquids. Because the magnetic bar can lose its coupling and stop spinning if the load is too heavy or thick. The strength of the magnetic field is limited, so the stir bar must be relatively small and lightweight.

Vortex mixers

This equipment is designed to mix small liquid samples quickly. While working, it creates a circular motion that forms a vortex in the liquid. When a container is pressed against the rubber cup at the top of the machine, the motor underneath moves the cup in a fast, circular motion. This motion causes the liquid inside the container to spin rapidly. Then it mixes the contents within seconds.

This equipment is designed to mix small liquid samples quickly. While working, it creates a circular motion that forms a vortex in the liquid. When a container is pressed against the rubber cup at the top of the machine, the motor underneath moves the cup in a fast, circular motion. This motion causes the liquid inside the container to spin rapidly. Then it mixes the contents within seconds.

Vortex mixers are ideal to blend small volumes, usually up to 50 mL. Many models also offer adjustable speeds, so users can control how gentle or vigorous the mixing should be. But they cannot mix multiple samples at once. When many samples need to be processed, it can take more time. In addition, since the device relies on contact with the container, it is more easily to spill and splash. Some delicate samples may also be damaged by the intense agitation if the speed is set too high.

Lab shakers

A lab shaker uses a shaking motion to create mixing. This motion can be orbital, linear, or reciprocal. The method mainly depends on the design of the machine. Lab shakers are useful to mix delicate samples or multiple samples at the same time. Most models have platforms with clamps or holders for test tubes, Erlenmeyer flasks, or microplates. This makes them ideal for applications like mixing reagents. Because there is no direct contact with the samples, shakers provide gentle mixing. So they are always used to deal with cells or fragile compounds.

But shakers may not be effective for high-viscosity liquids or large volumes. They are not strong enough to move thicker materials. In addition, overloading the shaker can cause vibration or imbalanced motion. It may affect performance.

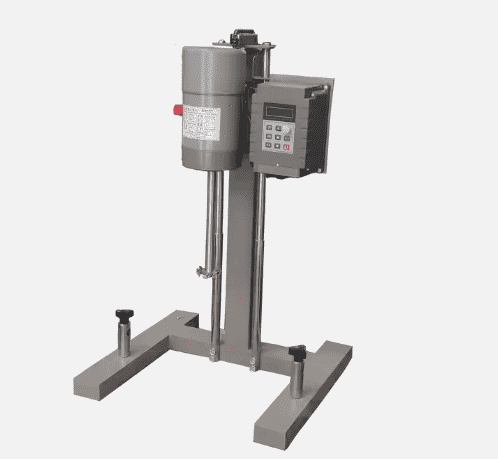

High-shear blenders

This machine has multiple functions. It can blend, emulsify, homogenize, or dissolve materials. It applies intense mechanical force through a rotor-stator system. As the rotor spins at high speed, it creates a strong shear field that breaks down particles and disperses them evenly. This method is always used to mix immiscible liquids like oil and water. If you pursue higher processing precision and finer particle size, a laboratory homogenizer is much better.

However, they are not suitable to blend heat-sensitive materials like proteins. Because they can generate a lot of heat due to the intense friction during mixing. Moreover, high-shear mixers usually require more maintenance and cleaning. So they require more costs than other mixing equipment in labs.

Laboratory rockers

This type gently moves samples back and forth like a seesaw. Rockers gently and consistently mix ingredients without creating bubbles or shear stress. They are commonly found in biology and chemistry labs, especially when working with gels, membranes, or fragile cells. But lab rockers are not ideal for thick and viscous samples or rapid mixing.

How to choose a mixer for your samples?

Material properties

Different pharmaceutical materials have different characteristics. Some materials are free-flowing, while others may be sticky. They require mixing equipment with specific handling methods. If the materials can react with metal, the mixer’s contact parts should be made of compatible materials, like stainless steel with special coatings. This prevents contamination and enhances the shelf life of your equipment.

Mixer capacity

The size of the mixer should match the volume of material that needs to be processed. If a mixer is too small, it may require multiple batches. This leads to longer processing times and possible variations between batches. On the other hand, if a mixer is too large for small-scale production, it can waste energy and increase cleaning time. For pharmaceutical production, it’s important to choose a model that fits your required volume. In addition, manufacturers should also check whether the mixer allows for flexible batch sizes without affecting mixing performance.

Mixing speed

Speed is an important factor. It affects how thoroughly and quickly materials are mixed. Sensitive pharmaceutical ingredients require gentle motion to prevent damage or heat buildup. Some may need high-speed mixing to ensure even distribution. If you need to handle various materials, you’d better choose mixers with adjustable speed settings. It allows more processing flexibility.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche