Vacuum Conveyors - for Powder

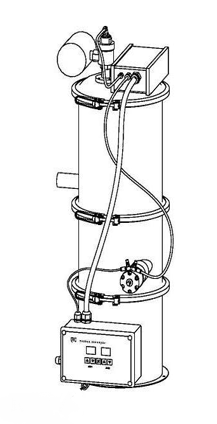

A vacuum conveyor is a dust-free, closed conduit conveying device that delivers particulate and powdered materials by means of vacuum suction. The device utilizes the difference in pressure between the vacuum and the environmental space to form a gas flow in the pipeline, which drives the movement of the powdered material, thereby completing the delivery of the powder.

This kind of conveying method can prevent dust environmental pollution, improve the working environment, and reduce environmental and personnel pollution of materials. It is widely used in various industries such as chemical, pharmaceutical, and food.

Features:

1. Safety and hygiene - The equipment is made of 304 stainless steel and meets GMP requirements.

2, strong conveying capacity - the inner wall is precision polished, does not bond materials, and the transfer efficiency is fast.

3, building-type structure - easy to disassemble, no dead ends, easy to clean.

4, light and easy to install - light weight, small size, low noise, no vibration.

Here are some faults that may occur while using vacuum conveyors:

| Faults | Reasons: | Solutions: |

| The conveyor is unable to transmit or the amount of transmitting is less |

The system air supply pressure has not reached 0.5-0.6MPA | Adjust the air supply pressure to 0.5-0.6MPA |

| Discharge door stacking powder | Clean the discharge door | |

| Sealing ring wear of the discharge door | Replace the seal | |

| Filter blocked | Blow or clean the filter | |

| Suction tube is blocked | Clean up the pipeline | |

| The clamp between the pump head and the hopper or clamp between the hoppers is not tightened. | Tighten the clamps | |

| Backflush system failure | Replace the backflush valve |

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche