What is Auger Filling Machine: A Complete Overview

Have you ever wondered how pharmaceutical and food companies go about their packaging? How do they ensure that the same products have equal quantities? All these are made possible by auger filling machines. Do you want to know more? Read on!

Packaging is the last phase of the manufacturing process. It involves filling the products into the packages, sealing, and labeling the products. Auger filling machines play critical roles in these processes. In this article, you will learn more about the operations of this equipment.

What is an Auger Filling Machine?

Auger fillers are excellent for filling dry powdered products into packages. They are ideal for the manufacturing and packaging process in the pharmaceutical and food industries. The foremost concern of manufacturers is the production of quality products. They find original materials that can help them make worthwhile products.

This approach is critical in helping them meet the needs of their customers. Yet, the fact that a product is effective is not enough to make customers happy. For example, it is great that a drug can cure an ailment. Yet, customers also want even products. In other words, they want products with the same quantity.

For example, they expect a 500 mg baking soda product to have this quantity. If they pay the same amount for products that have 400 mg instead of 500 mg, they will be unhappy. It can affect the brand image of the company and affect its customer retention and loyalty. Thus, manufacturing companies use auger filling machines to ensure accuracy.

Auger fillers are ideal for products such as spice powder, ground coffee, talc, and baking soda. Companies that make chemical powder, pepper powder, and flour also use this machine. It makes the process easier due to its accuracy and simplicity.

Auger Filler Machine Parts

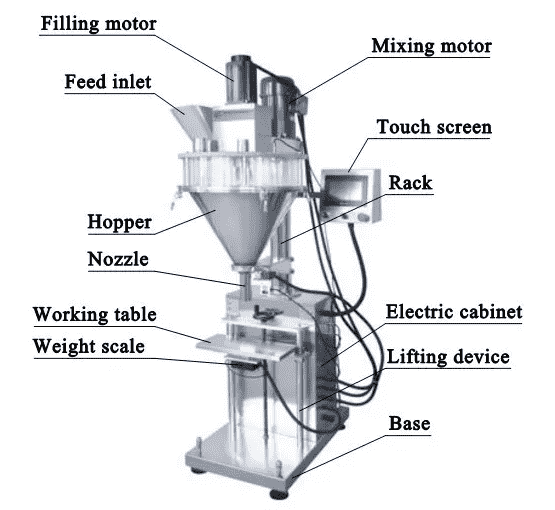

It is evident that these machines are not the same. Thus, some parts present in one model might be absent in others. Yet, most auger fillers have the following parts:

- Drive motor

- Blender motor

- Agitator or blender blades

- Screw auger

- Feeder inlet

- Inspection port

- Exhaust vent

- LCD HMI

- Emergency stop

- Visible window

- Hopper

- Funnel

- Power switch

These parts can be categorized into five major systems. The first is the drive assembly. It includes the motors, start/stop mechanism, and transmission mechanism.

The second is the hopper. While packing materials for the tooling, the hopper holds them temporarily. From the hopper, the items will be supplied to the tooling for the next stage.

The third is the tooling. The tooling consists of the funnel, the auger, and the agitator. They can be changed depending on the need of the operator. Its auger blade has a constant rotation speed for feeding products out of the funnel. This feature contributes immensely to the accuracy of this machine.

Its agitation blades break down any product bridge to ensure the production of even powders. It also de-aerates the powder while rotating opposite the auger. Agitation blades prevent rat-holing through their extension to the funnel’s throat. They also ensure that the auger flights are never empty.

The fourth is the support structure, which offers a base for the rest of the structure. The final one is the control system, which helps the operator to instruct the machine.

How Does an Auger Filling Machine Work?

Auger filling machines are of various kinds. They can be categorized into:

- Dual-head automatic auger fillers

- Single-headed automatic auger fillers

- Single head auger filler with embedded check weight

- Multi-head automatic twin auger filling machine

- Economic single-head automatic auger fillers

Regardless of the type of auger filler you have, they have similar working principles. Here are the steps of operation of this machine:

Step 1 – Setting the Filling Parameters

It begins with the setting of the filling parameters by the operator. The operator does this on the control system of the machine.

Step 2 – Feeding the Containers

In an automatic auger filler, a power conveyor system aids the automatic queuing of the containers. But in semi-automatic or manual models, it is different. In such models, the operator has to carry out this process manually.

Step 3 – Feeding the Products to the Auger Screw

The next stage is when the operator feeds the products to the auger screw. It involves the use of the hopper. Some auger filling machines have scales for measuring the products. But these machines are mainly volumetric fillers.

Auger drives rotate at a constant speed. This operation makes it possible to feed the products into the hopper’s tube. Thus, this machine creates homogeneous mixtures effortlessly. Its working principle also prevents inconsistencies in the formation process.

Applications Of Auger Fillers

Auger filling machines have wide applications. They are useful in the pharmaceutical, food, and chemical industries. The auger’s lower parallel flights have precise volumes. They ensure that the doses are the same. Typically they offer accuracies in the range of ± 0.5% to 2%, which makes them reliable machines.

This wide range of applications is possible due to the versatility of this machine. In these industries, auger fillers have the following application:

- Filling containers with syrups, gels, and drugs in powder forms in the pharmaceutical industry.

- Filling containers with coffee, tea, spices, stews, dough, and flour in the food industry.

- Filling containers with detergents, cosmetics, and creams in the chemical industry.

Yet, it is important that the operator is careful when filling in some items. For example, fruits, vegetables, tobacco, and cornflakes are delicate for this machine. The engine might crush them in the process of filling them into containers.

Why You Need an Auger Filling Machine?

By leveraging auger technology, auger fillers are reliable equipment. They are useful in the food, chemical, and pharmaceutical industries for the following reasons:

Accuracy and Reliability

Manually filling products into packages can be stressful. Thus, it is impossible to write off human errors, especially when you start getting tired. However, with auger fillers, you can fill many packages with accuracy. As long as you program the machine correctly, there is no cause for alarm.

These heavy-duty engines can work for prolonged periods with a high level of accuracy. So, they are reliable for commercial purposes in the food, chemical, and pharmaceutical industries.

Saves Time and Energy

Most auger machines have user-friendly interfaces that make them easy to operate. So, you will save yourself a lot of stress and energy by investing in an auger filler. It is never easy to maintain consistency in the manufacturing industry for years. Thus, you need equipment that will make things simpler and easier for you.

Auger fillers are such machines. They make life easier with their automated system. They help you do so much within a short period. Thus, they increase your efficiency and save your energy.

Safety

Safety is a critical factor in the food, chemical, and pharmaceutical industries. It is natural that you want your employees to be safe during the manufacturing process. Auger fillers contribute to your ability to achieve this goal. They help you to avoid dust explosions with their explosion-proof mixing. Thus, they reduce the chances of contamination.

More Revenue

When you can do more in shorter periods, it will enhance your productivity. The result of an increase in your efficiency will lead to the production of more products. Thus, you will be able to meet the demands of your customers, increasing your revenue.

iPharMachine’s Auger Filling Machine

Now that you understand the advantages of auger fillers, it is great that you invest in one. iPharMachine supplies small or medium-sized pharmaceutical equipment. It uses 100% safe raw materials to produce its machines. Some of the products of the company include blister packing machines, bottling lines, tablet press machines, and capsule filling machines.

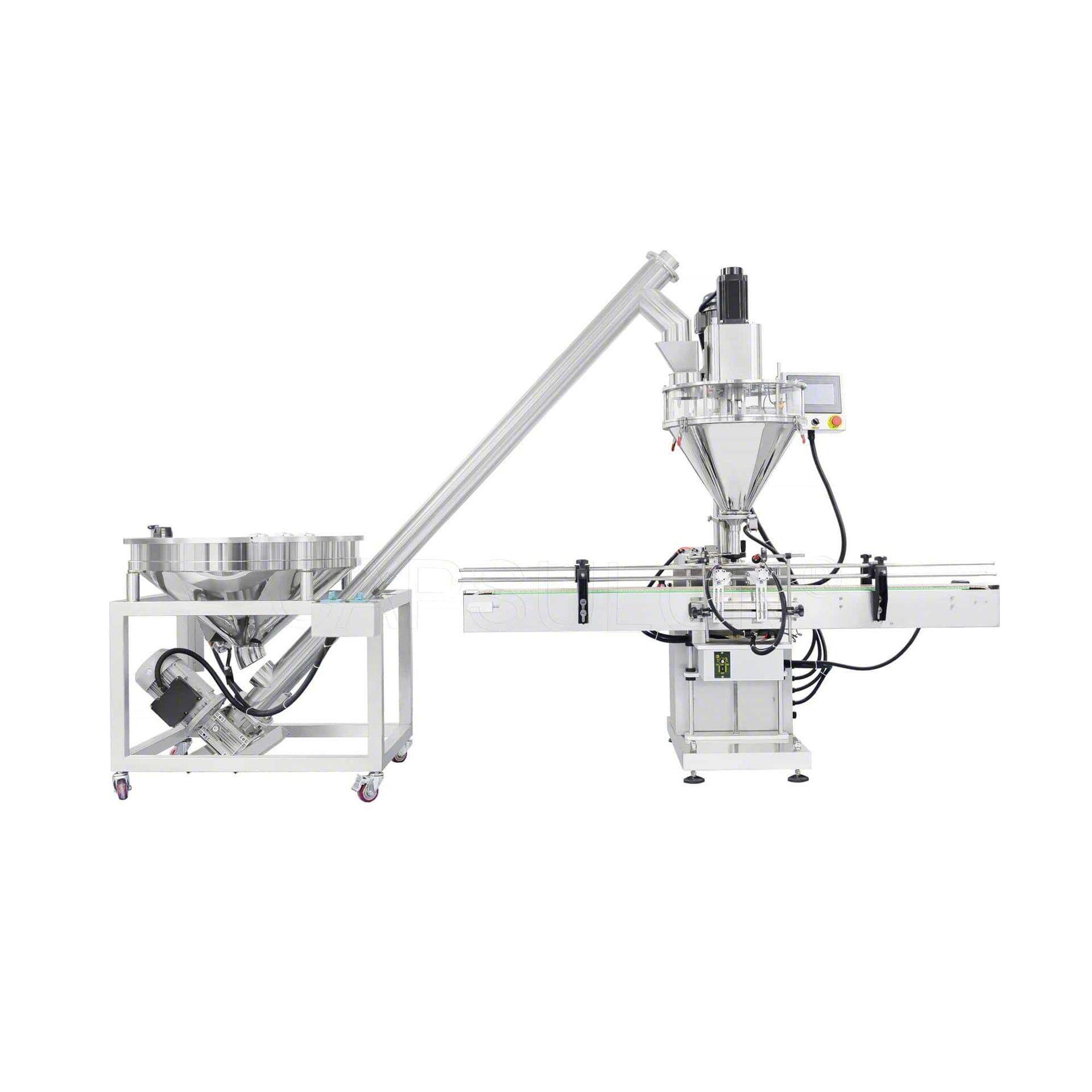

Its auger filler is the Automatic Powder Filling Machine CN-HZFB. This machine has a simple structure despite its effectiveness. Its wide adaptability and flexible combination are some of its exciting features.

Its accuracy and low failure rate are some of the reasons pharmaceutical companies invest in this product. It also features automatic material cleaning and calculation. Below is a summary of its features:

- Dust control system to prevent contamination

- Easy to clean and maintain

- Easy to control even for new users

- Sturdy, compact, stainless steel design

- Automatic error correction

- High sensitivity

- Automatic feeding device

- Material level control

- Strong reliability

- Applicable to the pharmaceutical, chemical, and food industry

Final Words

Auger fillers are increasingly popular in the food, chemical, and pharmaceutical industries. This device makes the manufacturing process easier and faster. So, it is not surprising that many companies invest in these engines to increase their productivity. iPharMachine’s automatic powder filling machine is one of the best in the market. Invest in one today to take your manufacturing process to the next level.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche